HD2 Series Inverter Basic Operation Guidelines

-73-

synchronous motor 1) can be obtained via calculation.

4. Motor autotuning can be carried out on current motor only, if you need to perform autotuning on

the other motor, switch over the motor through selecting the switchover channel of motor 1 and

motor 2 by setting the ones of P08.31.

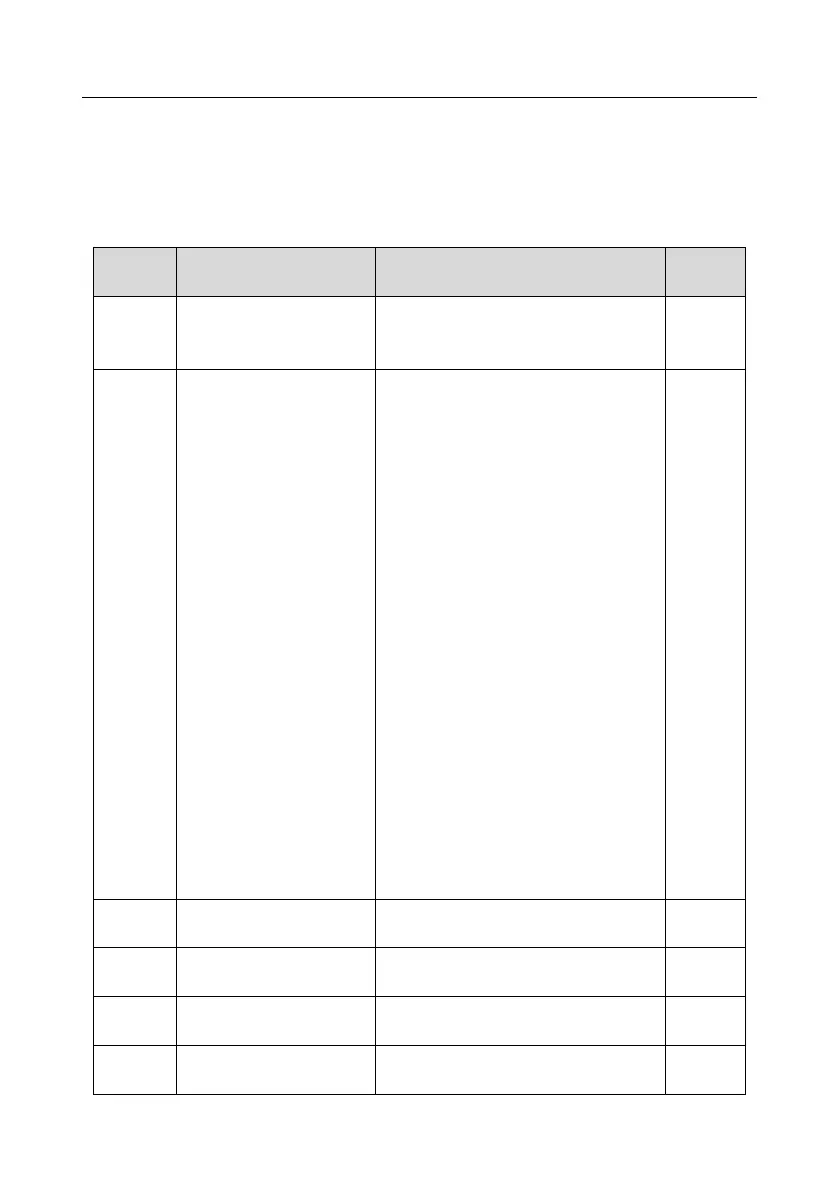

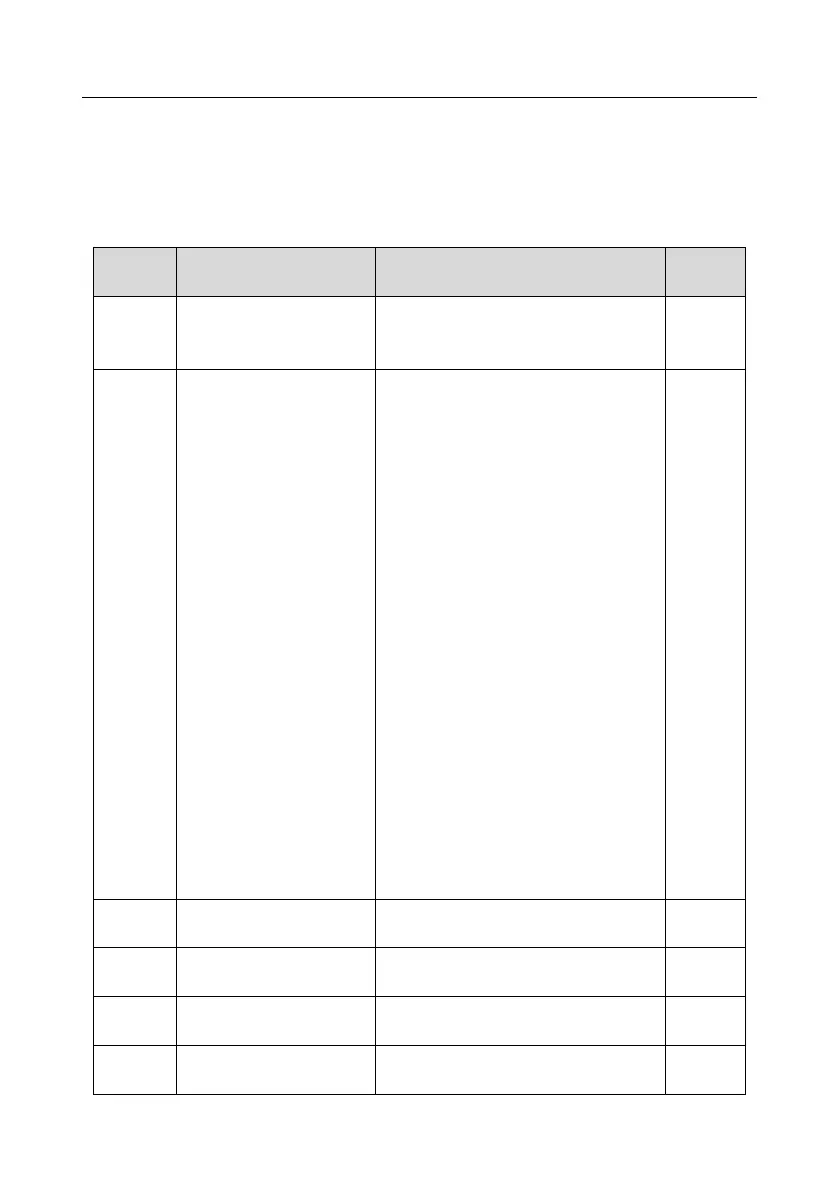

Related parameter list:

0: No operation

1: Rotary autotuning 1; carry out

comprehensive motor parameter

autotuning; rotary autotuning is used in

cases where high control precision is

required.

2: Static autotuning 1 (comprehensive

autotuning); static autotuning 1 is used in

cases where the motor cannot be

disconnected from load.

3: Static autotuning 2 (partial autotuning);

when current motor is motor 1, only

P02.06, P02.07 and P02.08 will be

autotuned; when current motor is motor

2, only P12.06, P12.07 and P12.08 will

be autotuned.

4: Rotary autotuning 2, which is like

rotary autotuning 1 but is only applicable

to asynchronous motors.

5: Rotary autotuning 3 (partial

autotuning), which is only applicable to

asynchronous motors.

Loading...

Loading...