IS620P User Manual Chapter 6 Troubleshooting

- 119 -

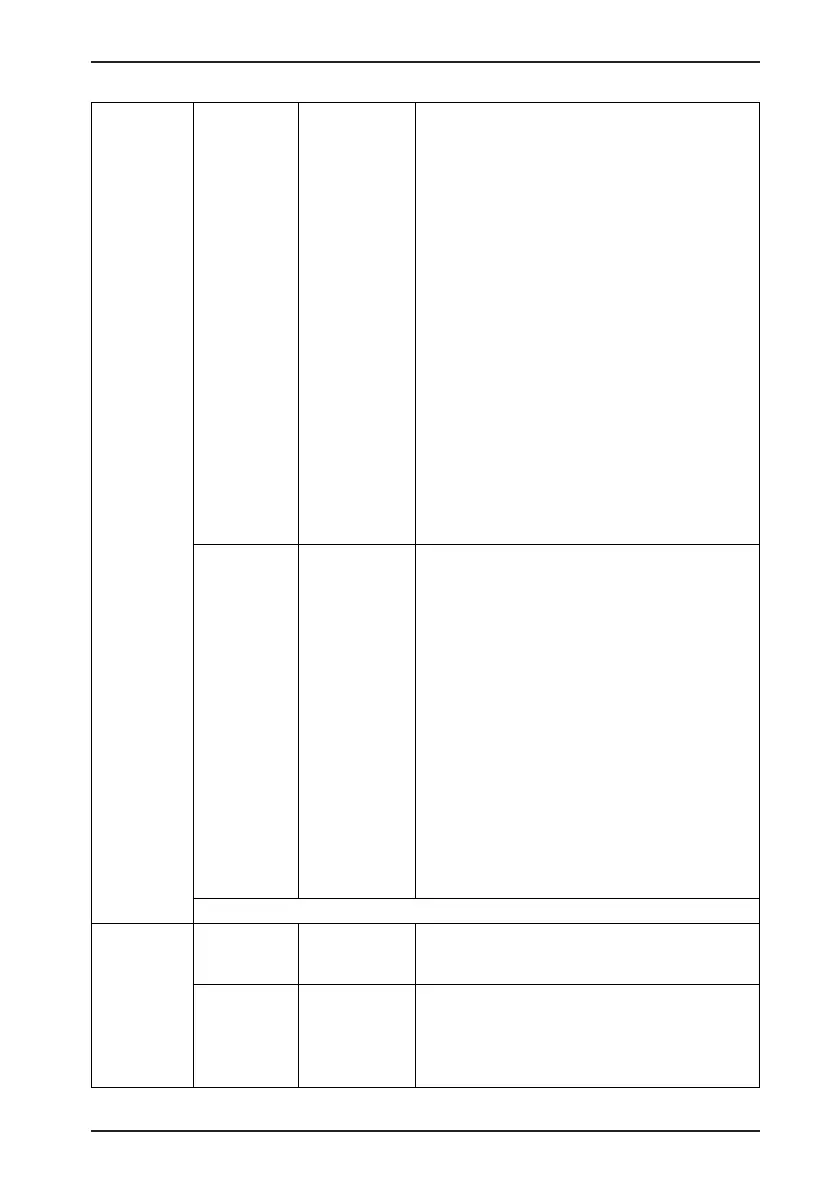

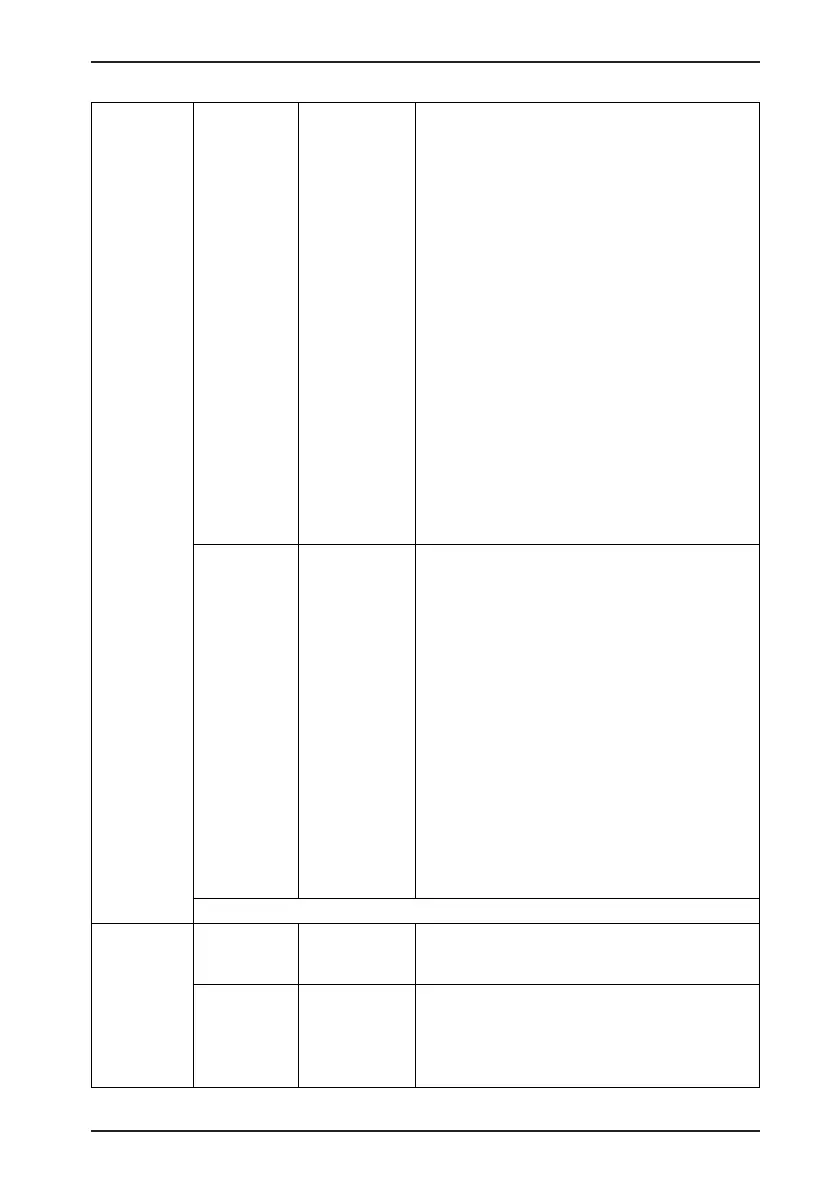

Input the

torque

reference

The servo

motor does not

rotate.

The internal

torque reference

(H0B-02) is 0.

•

The AI wiring is incorrect.

When the torque reference is input through

AI, check whether the AI is wired correctly by

referring to Chapter 3 Wiring of Servo System.

•

The torque reference selection is incorrect.

Check whether H07-02 (torque reference

source) is set correctly.

•

The torque reference is not input

When AI is selected to input the torque

reference, check whether the AI related

parameters in group H03 are set correctly rst.

Then check whether the input voltage is correct

by observing the voltage on oscilloscope or

viewing the AI sampling voltage in H0B-21 or

H0B-22.

When digital setting is used to set toque

reference, check whether H07-03 (keypad

setting value of torque reference) is 0.

When communication is used to set toque

reference, check whether H31-11 (torque

reference set via communication) is 0.

The servo

motor rotates

in the reverse

direction.

The internal

torque reference

(H0B-02) is

negative.

•

When AI is selected to input the torque

reference, check whether the polarity of input

signal is reversed. You can conrm the condition

by using an oscilloscope or viewing H0B-21 or

H0B-22.

•

When digital setting is used to set the speed

reference, check whether H07-03 (keypad

setting value of torque reference) is smaller than

0.

•

When communication is used to set toque

reference, check whether H31-11 (torque

reference set via communication) smaller than

0.

•

Check whether the DI function FunIN.25:

ToqDirSel (torque reference direction) has been

allocated and whether the logic of corresponding

DI is effective.

•

Check whether H02-02 is set correctly.

■ After the preceding causes are removed, the servo motor can rotate.

The servo

motor jitters at

low speed.

The motor

speed is not

steady.

The gain is set

unreasonably.

•

Perform automatic gain adjustment based on

section 4.5.2 Automatic Gain Adjustment.

The motor

shaft vibrates

left and right.

The load inertia

ratio (H08-15) is

too large.

•

If the servo motor can run safely, perform the

inertia auto-tuning based on section 4.5.1 Inertia

Auto-tuning

•

Perform automatic gain adjustment based on

section 4.5.2 Automatic Gain Adjustment.

Loading...

Loading...