IS620P User Manual Chapter 4 Running and Commissioning

- 75 -

4.1 Use of the Position Control Mode

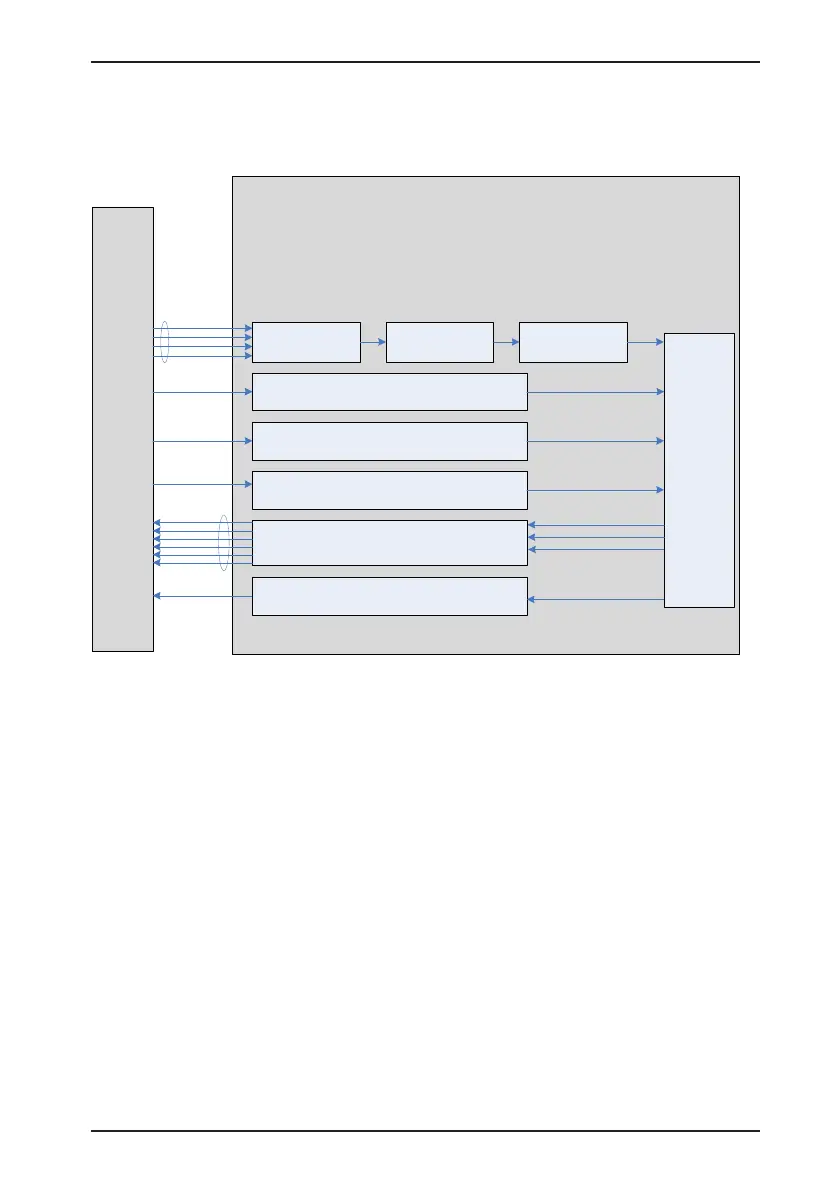

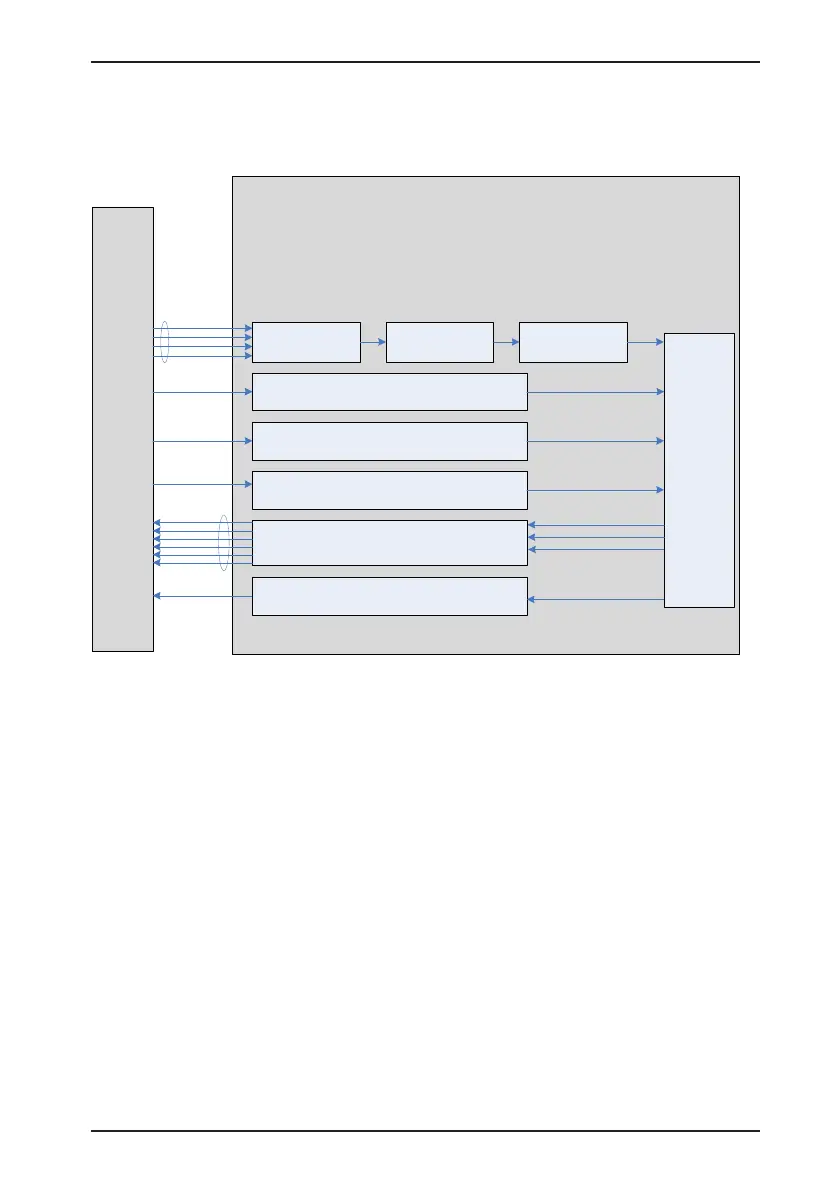

Figure 4-1 Diagram of the position control mode

Reference input

setting

Position

regulator

Host

controller

Pulse input

H05-00 Position

reference source

H05-01 Pulse reference

input terminal selection

H05-15 Pulse reference

form

H

05-

07 Electronic gear ratio 1

(numerator)

H05-09 Electronic gear ratio 1

(

denominator)

H

05-11

Electronic gear ratio 2

(numerator)

H05-13 Electronic gear ratio 2

(denominator)

H05-02 Pulses for one motor

revolution

H05-04 First-order low-

pass filter time constant

H05-06 Filter time

constant of average value

of position references

H05-20 Output condition of positioning

completed signal (COIN)

H05-

21 Threshold for positioning

completed

Electronic gear

ratio

Position

reference filter

Reference direction selection

POSDirSel

input

INHIBIT

input

Frequency-division output

Frequency-

division pulse

output

Pulse input forbidden

Position deviation cleared

COIN output

Positioning completed

Servo drive

H05-17 Encoder

frequency-division pulses

H05-38 Servo pulse

output source

CLR input

The position control mode is the most common mode of the servo drive. The main use

procedure is as follows:

1. Connect the power cables of the main circuit and control circuit of the servo drive, motor

power cables, and encoder cables correctly. After power-on, the keypad of the servo drive

displays "rdy", indicating that the wiring is correct.

2. Perform trial jog running by pressing keys and ensure that the motor can run properly.

3. Connect the signals of terminal CN1, such as the pulse direction input, reference pulse

input, and required DI/DO signals (servo drive enabled and positioning completed)

according to Figure 4-2.

4. Perform the setting related to the position control mode. Set the DI/DO functions in groups

H03 and H04 based on actual requirements. You may also need to set the home return

and frequency-division functions based on actual requirements.

5. Enable the servo drive. Send a position reference from the host controller to enable

the servo motor to rotate. Make the motor rotate at a low speed and check whether the

rotating direction and electronic gear ratio are normal. Then, adjust the gain. For details,

see the commissioning procedure in section 4.5.

Loading...

Loading...