IS620P User Manual Chapter 2 Mounting Dimensions of Servo System

- 19 -

2.1.3 Installation Precautions

Table 2-2 Installation precautions

Item Description

Rust-proof

treatment

Wipe up the antirust agent at the motor shaft end before installing the servo motor,

and then take rust-proof treatment.

Encoder

•

Do not strike the shaft end during installation. Failure to comply will lead to

damage to the internal encoder.

•

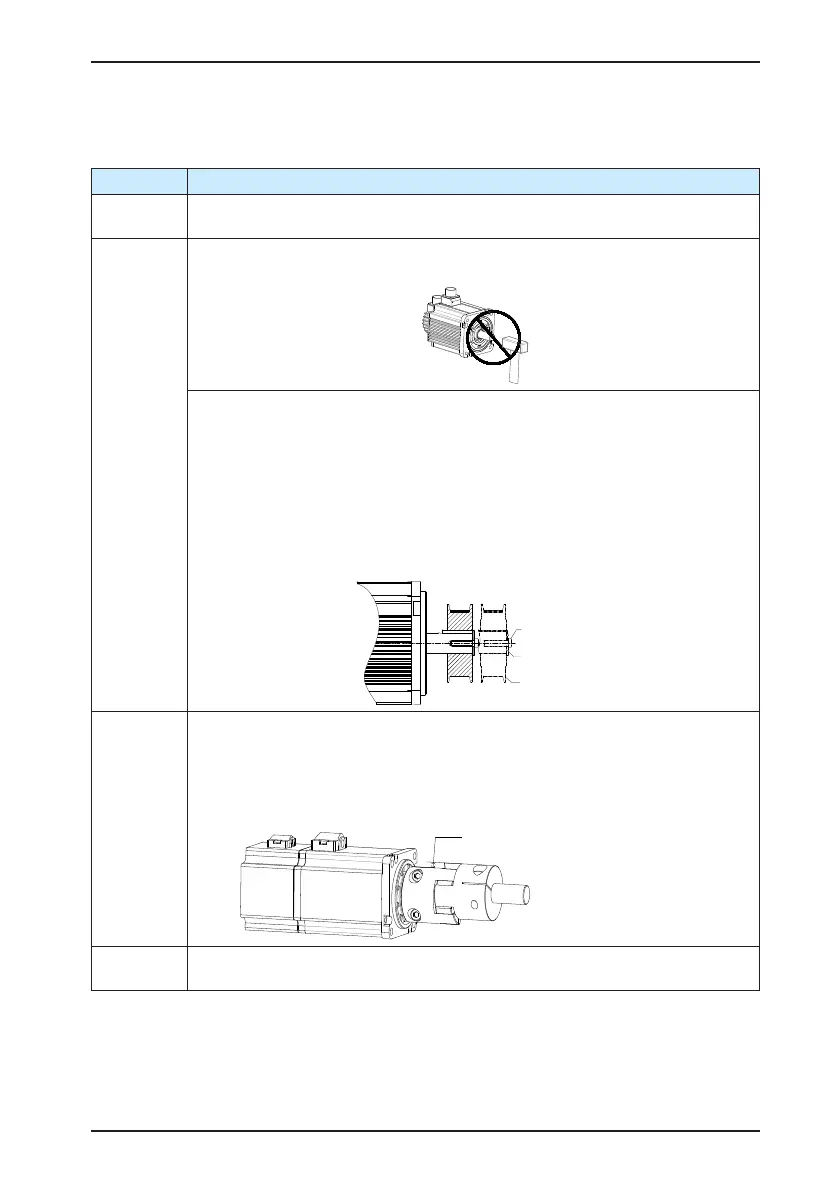

Use the screw hole at the shaft end when mounting a pulley to the servo motor

shaft with a keyway. To t the pulley, insert a double-end screw into the screw hole

of the shaft, put a washer against the coupling end, and then use a nut to push

the pulley in.

•

For the servo motor shaft without a keyway, use friction coupling or the like.

•

When removing the pulley, use a pulley remover to protect the shaft from suffering

severe impact from load.

•

To ensure safety, install a protective cover or similar device on the rotary area

such as the pulley mounted on the shaft.

Flange coupling,

pulley

Washer

Screw

Alignment

Align the shaft of the servo motor with the shaft of the equipment and then couple

the shafts. When installing the servo motor, make sure that the alignment accuracy

satises the requirement as described in the following gure. If the shafts are not

properly aligned, vibration will be generated and may damage the bearings and

encoder.

Measure the distance at four different

positions on the circumference. The difference

between the maximum and minimum

measurements must be 0.03 mm or less.

Installation

direction

The servo motor can be installed horizontally or vertically.

Loading...

Loading...