Chapter 3 Wiring of Servo System IS620P User Manual

- 62 -

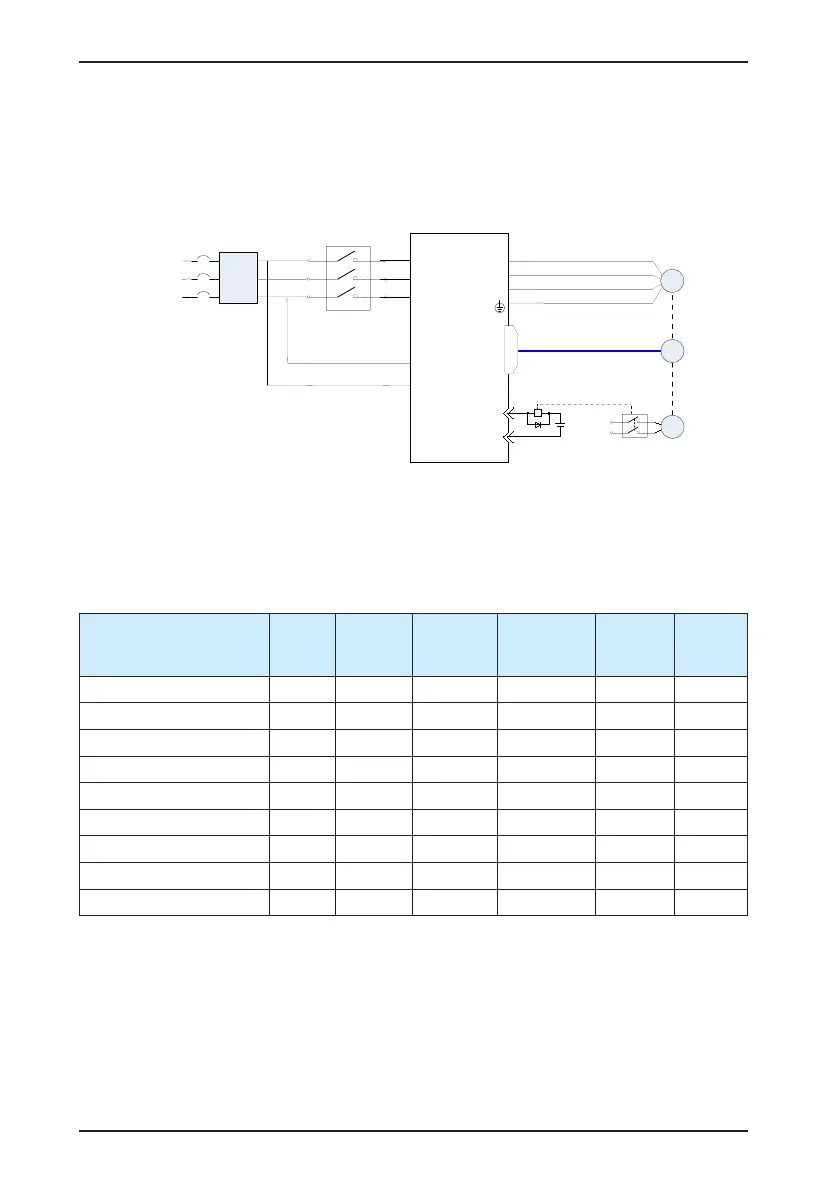

1) Wiring example of holding brake

The connector of the holding brake is of no polarity. You needs to prepare a 24 V external

power supply. The following gure shows the standard wiring of brake signal (/BK) and power

supply of the brake.

Figure 3-10 Wiring of the holding brake

Brake control relay

Servo drive

CN1

BK-RY

+24V

DO5+(/BK+)

DO5-(/BK-)

+24V

(Brake power supply)

Encoder

Brake

Motor

EMI

filter

L1C

L2C

Three-phase

220/380 VAC

R

S

T

U

V

W

M

CN2

PG

BK

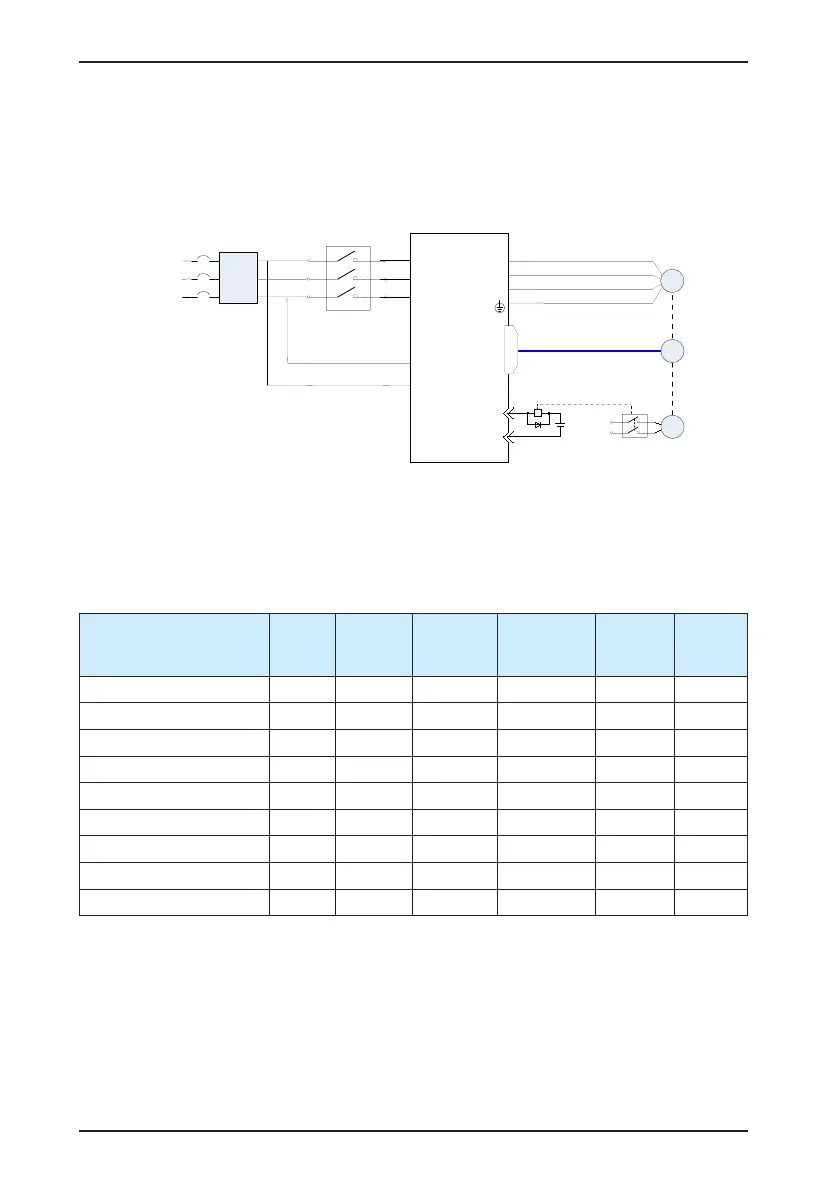

2) Wiring precautions

a. To decide the length of the cable on the motor brake side, consider voltage drop caused

by the cable resistance. The input voltage must be at least 21.6 V to make the brake

work. The following table lists brake specications of ISMH servo motors.

Table 3-18 Brake specications

Servo Motor Model

Holding

Torque

(N·m)

Supplied

Voltage

(V)±10%

Resistance

(Ω) ±7%

Supplied

Current

Range (A)

Release

Time (ms)

Applying

Time

(ms)

ISMH1-10B 0.32 24 96 0.23–0.27 10 30

ISMH1-20B/40B 1.3 24 82.3 0.25–0.34 20 50

ISMH1-75B 2.39 24 50.1 0.40–0.57 25 60

ISMH2-10C/15C/20C/25C 8 24 25 0.81–1.14 30 90

ISMH2-30C/40C/50C 16 24 21.3 0.95–1.33 60 120

ISMH3-85B/13C/18C 16 24 21.3 0.95–1.33 60 120

ISMH3-29C/ 44C/55C/75C 48 24 13.7 1.47–2.07 100 230

ISMH4-40B 1.3 24 82.3 0.25–0.34 20 50

ISMH4-75B 2.39 24 50.1 0.40–0.57 25 60

b. The brake shall not share the same power supply with other devices. Otherwise, the

brake may conduct false operation due to voltage or current drop resulted from working of

other devices.

c. Cables of 0.5 mm

2

and above are recommended.

Loading...

Loading...