Chapter 6 Troubleshooting IS620P User Manual

- 142 -

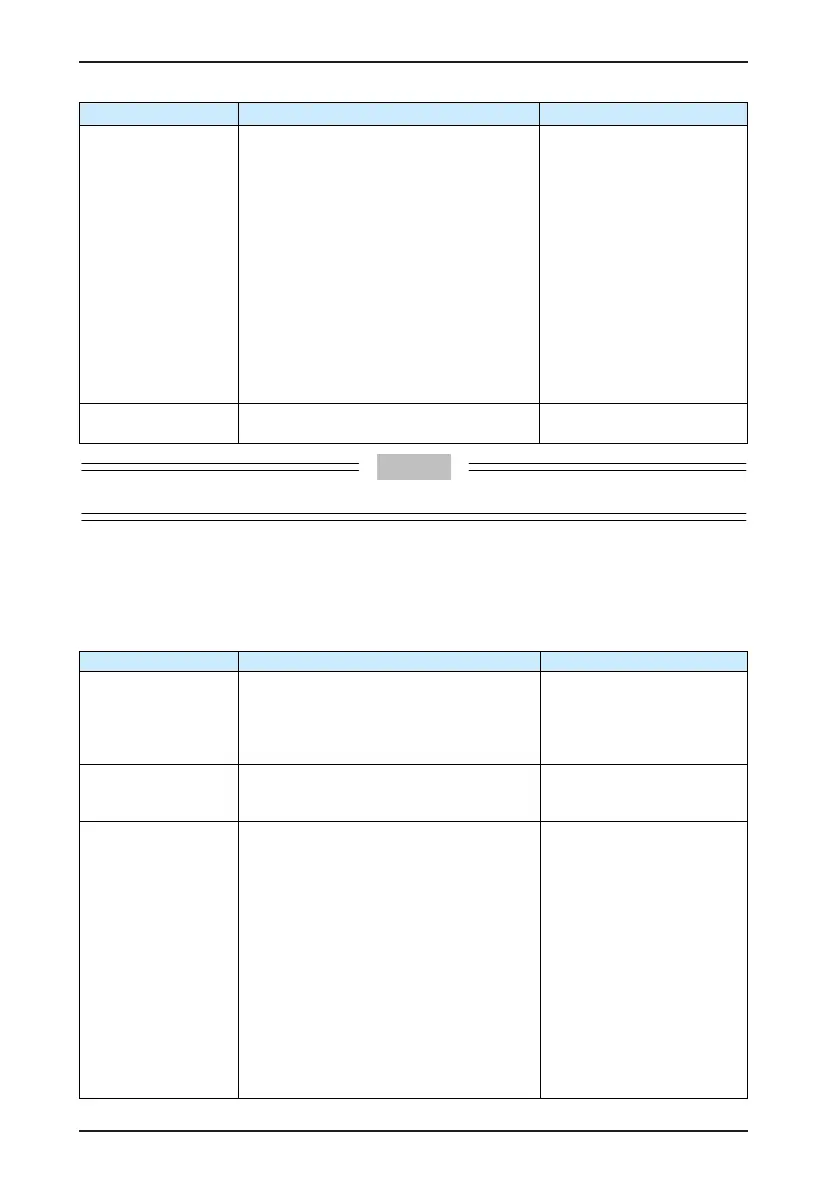

Cause Conrming Method Corrective Action

6. Locked-rotor occurs

due to mechanical

factors, resulting

in very heavy load

during running.

•

Check the running reference and the

actual motor speed (H0B-00) by using

the drive debugging platform of Inovance

or the operation panel.

Running reference in the position control

mode: H0B-13 (input reference pulse

counter)

Running reference in the speed control

mode: H0B-01 (speed reference)

Running reference in the torque control

mode: H0B-02 (internal torque reference)

Check the running reference in

corresponding mode is not 0 but the

motor speed is 0.

Eliminate mechanical factors.

7. The servo drive is

faulty.

•

The fault remains after the servo drive is

powered off and then powered on again.

Replace the servo drive.

You can clear the fault or re-power on the system 30s after occurrence of the overload fault.

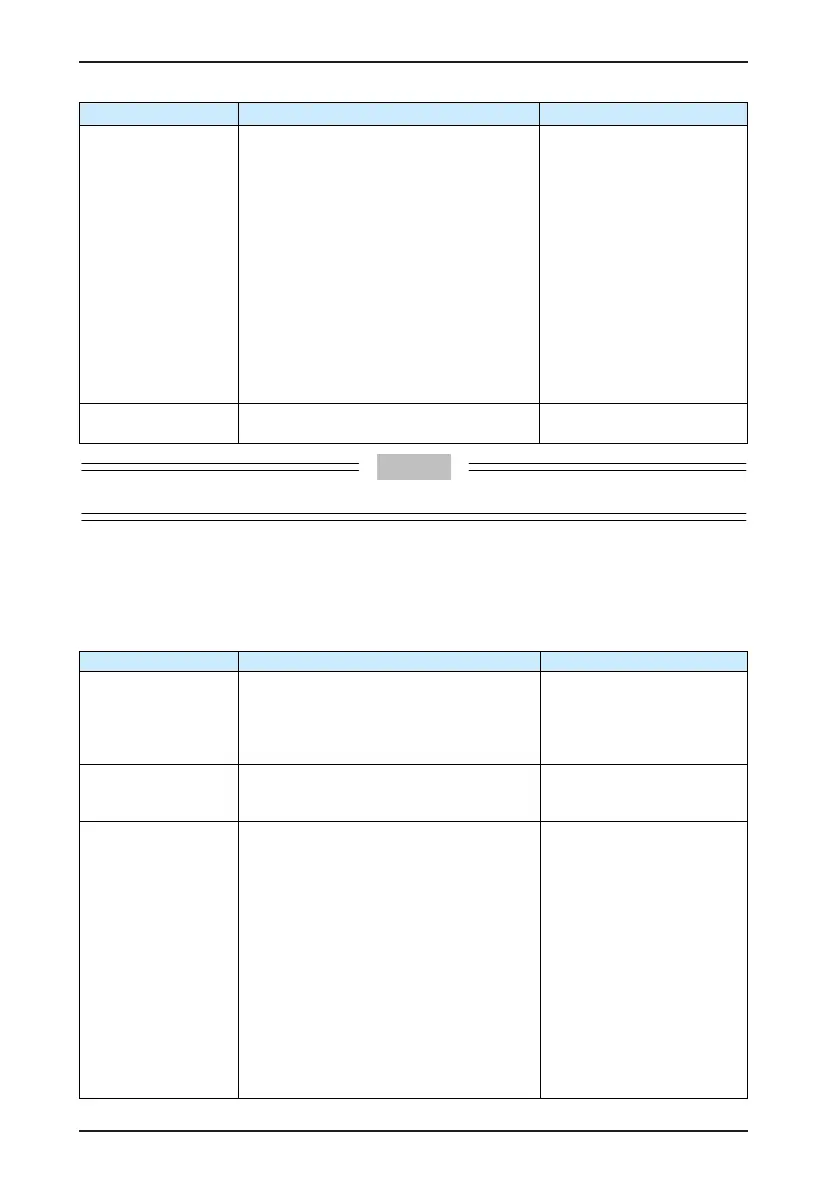

27. Er.630: Overheat protection of locked-rotor motor

Cause:

•

The actual motor speed is lower than 10 rpm but the torque reference reaches the limit.

The duration reaches the value set in H0A-32.

Cause Conrming Method Corrective Action

1. The power output

phase (UVW) loss

or incorrect phase

sequence occurs on

the servo drive.

•

Perform motor trial running when the

motor has no load and check the motor

wiring.

Connect the motor cables

correctly again or replace

them.

2. The UVW cables

or the encoder cable

breaks.

•

Check the wiring.

Connect the motor cables and

encoder cable correctly again

or replace them.

3. The motor rotor

is locked due to

mechanical factors.

•

Check the running reference and the

actual motor speed (H0b-00) by using the

drive debugging platform of Inovance or

the operation panel.

Running reference in the position control

mode: H0B-13 (input reference pulse

counter)

Running reference in the speed control

mode: H0B-01 (speed reference)

Running reference in the torque control

mode: H0B-02 (internal torque reference)

Check whether the running reference

in corresponding mode is not 0 but the

motor speed is 0.

Eliminate mechanical factors.

Loading...

Loading...