Chapter 2 Mounting Dimensions of Servo System IS620P User Manual

- 20 -

Item Description

Handling oil

and water

Conrm the IP level of the servo drive in water drop applications (except for the

shaft-through portion). In the environment where the shaft-through portion is

exposed to oil drops, select and use a servo motor with an oil seal.

Observe the following conditions when using the servo motor with oil seal:

•

Keep the oil level under the oil seal lip during usage.

•

Use the oil seal in favourably lubricated condition.

•

Avoid oil accumulation at the oil seal lip when using the servo motor with its shaft

in upward direction.

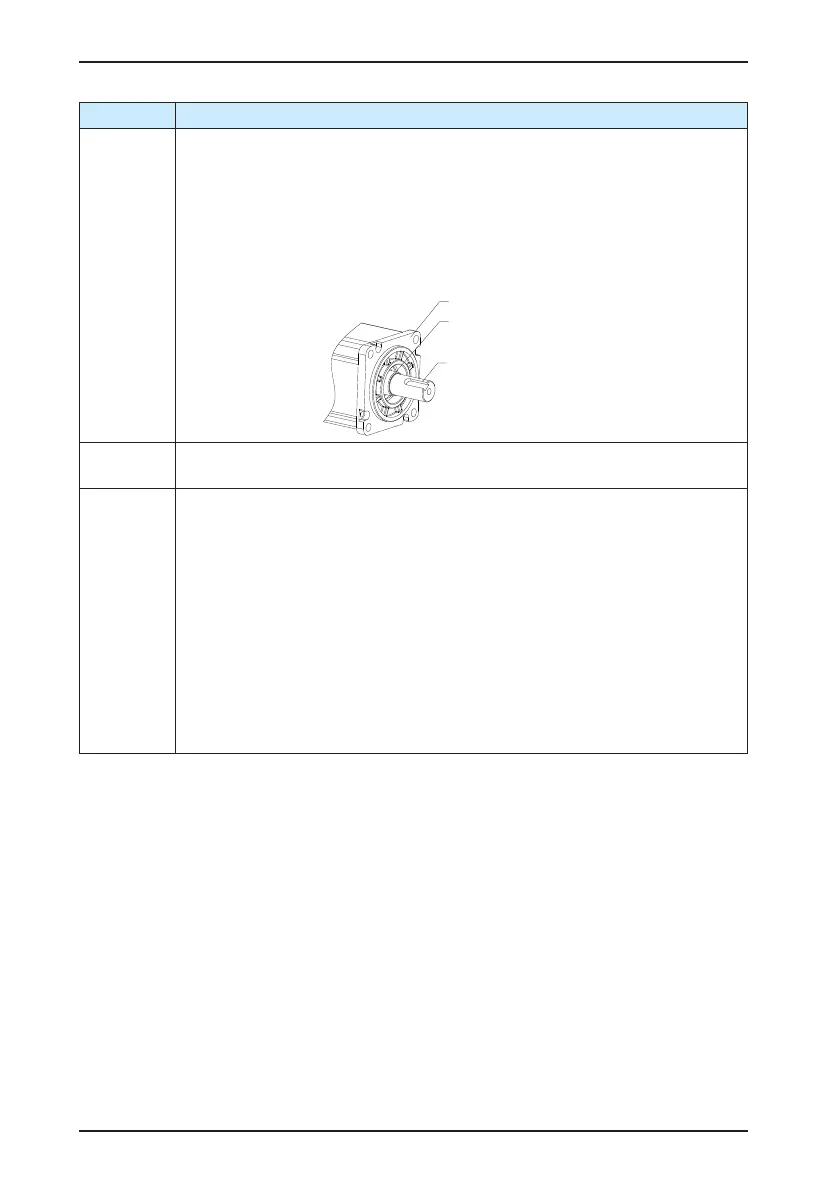

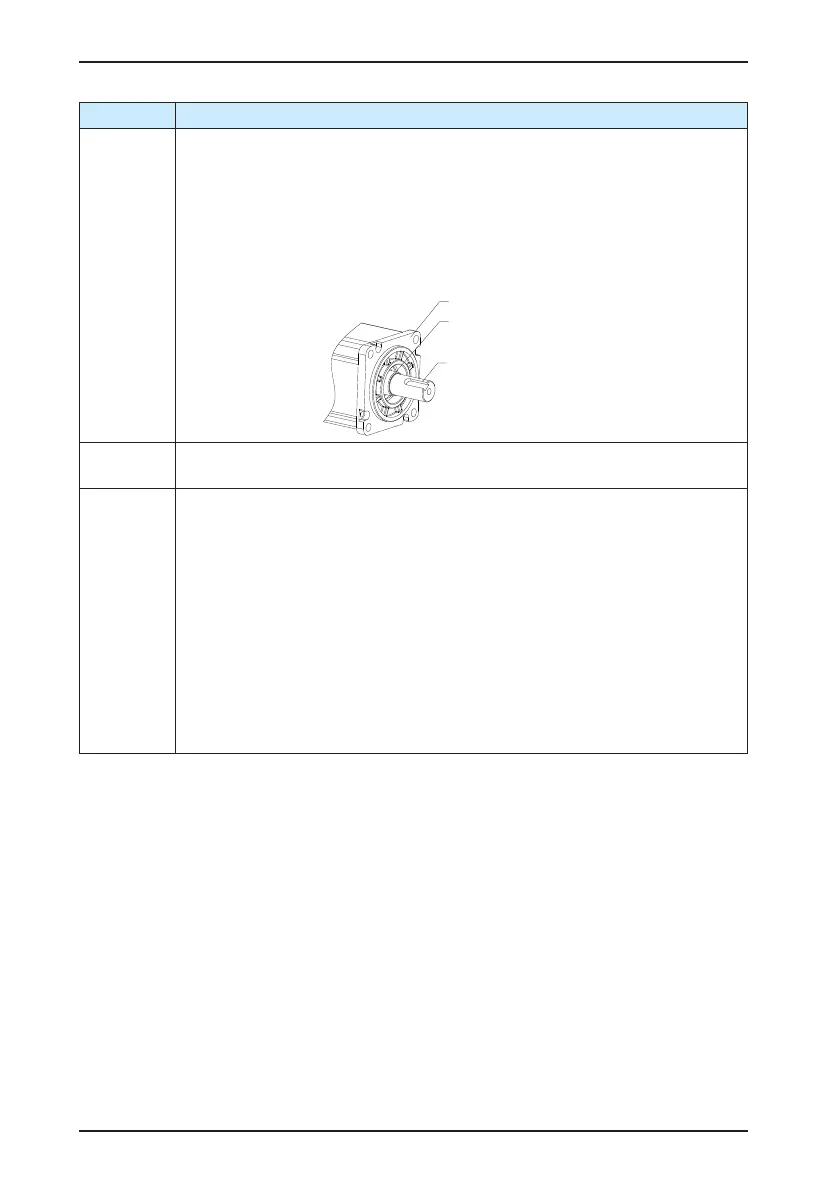

Flange face

Shaft-through portion

(indicates the clearance of the shaft

extension portion from the motor end face)

Transmission

shaft

Stress of

cables

Do not bend or apply tension to the cables, especially the signal cables whose core

wire is 0.2 or 0.3 mm thick. Do not pull the cables tightly during wiring.

Connectors

•

When connecting the connectors, make sure there is no waste or sheet metal

inside the connectors.

•

When connecting a connector to servo motor, be sure to connect the servo motor

main circuit cables rst and ensure reliable grounding of the cable. If the encoder

cable is connected rst, the encoder may fail because of voltage difference

between PEs.

•

Make sure the pins are correctly arranged during wiring.

•

The connector is made up of resins. Do not apply shock to prevent damage to the

connector.

•

When moving a servo motor with cables connected, hold the main body of the

servo motor. If you hold the cables only, connectors and cables may be damaged.

If bending cables are used, do not attach stress on the cables during wiring.

Failure to comply may cause damage to the connectors.

2.2 Installation of the Servo Drive

2.2.1 Installation Location

1. The servo drive of plastic housing is a whole unit built-in product operated through remote

control and needs to be installed in the nal system. The nal system must have the

required reproof cover, electrical protective cover and mechanical protective cover, and

satisfy the regional laws & regulations and related IEC requirements.

2. Install the servo drive inside a cabinet free of sun light and rain.

3. Do not install the servo drive in an environment with corrosive or inammable gases or

combustibles, such as hydrogen sulde, chlorine, anmonia, sulphur gas, chloridize gas,

acid, soda and salt.

4. Do no install the servo drive in the environment with high temperature, moisture, dust and

metal powder.

5. Install the servo drive in a place with no vibration.

Loading...

Loading...