IS620P User Manual Chapter 4 Running and Commissioning

- 93 -

•

The signal cables and power cables must be laid separately with the distance at least above 30

cm.

•

When the signal cable is not long enough and an extension cable needs to be connected, ensure

that the shield is connected reliably and the shielding and grounding are reliable.

•

+5V is referenced to GND, and +24V is referenced to COM-.

•

The current must not exceed the maximum allowable value. Otherwise, the servo drive cannot

work properly.

4.3.2 Function Code Setting of the Torque Control Mode

1. Torque reference input setting

a. Torque reference source

In the torque control mode, there are two torque reference sources, source A and source B,

set as follows:

•

Digital setting is performed on the keypad, and the percentage of the torque relative to the

rated torque set in H07-03 is used as the torque reference.

•

The analog setting means that the externally input analog voltage signal is converted to

the torque reference signal of motor speed. The relationship between the analog and the

torque reference can be dened based on actual requirements.

The related function codes are set in the following table.

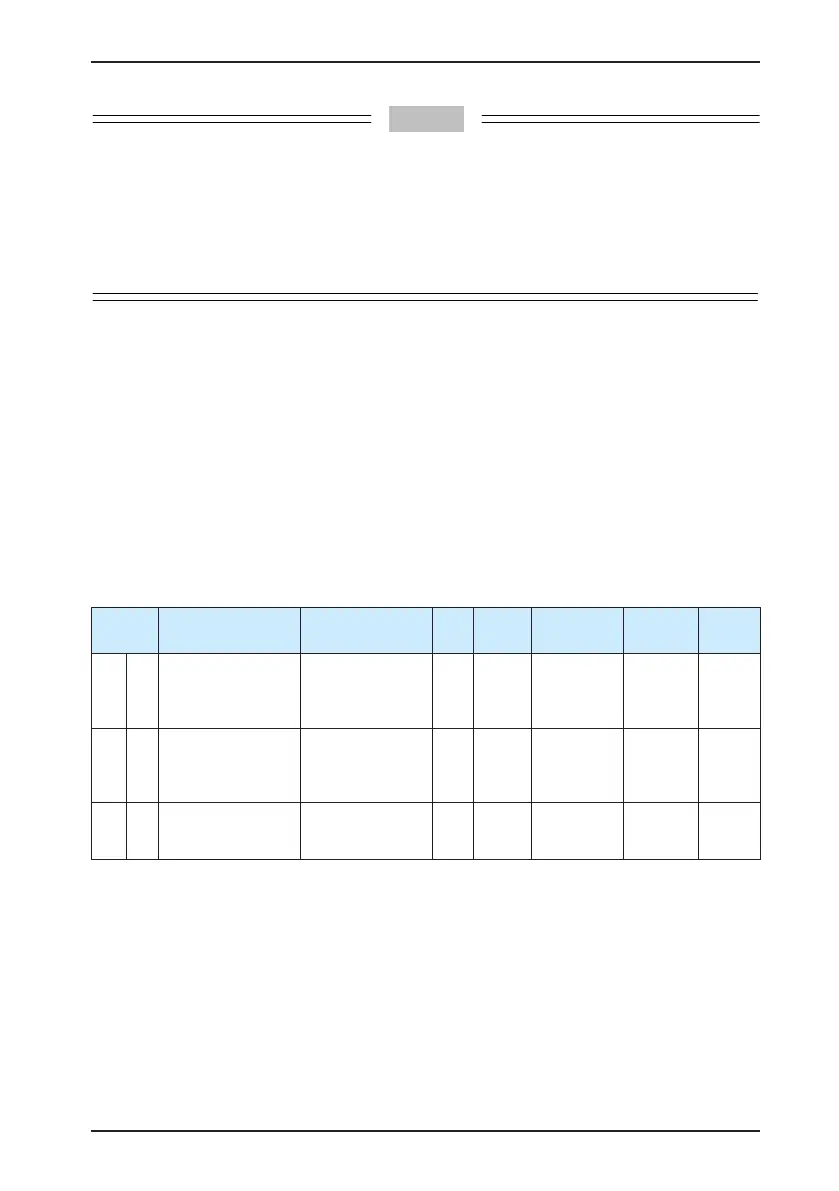

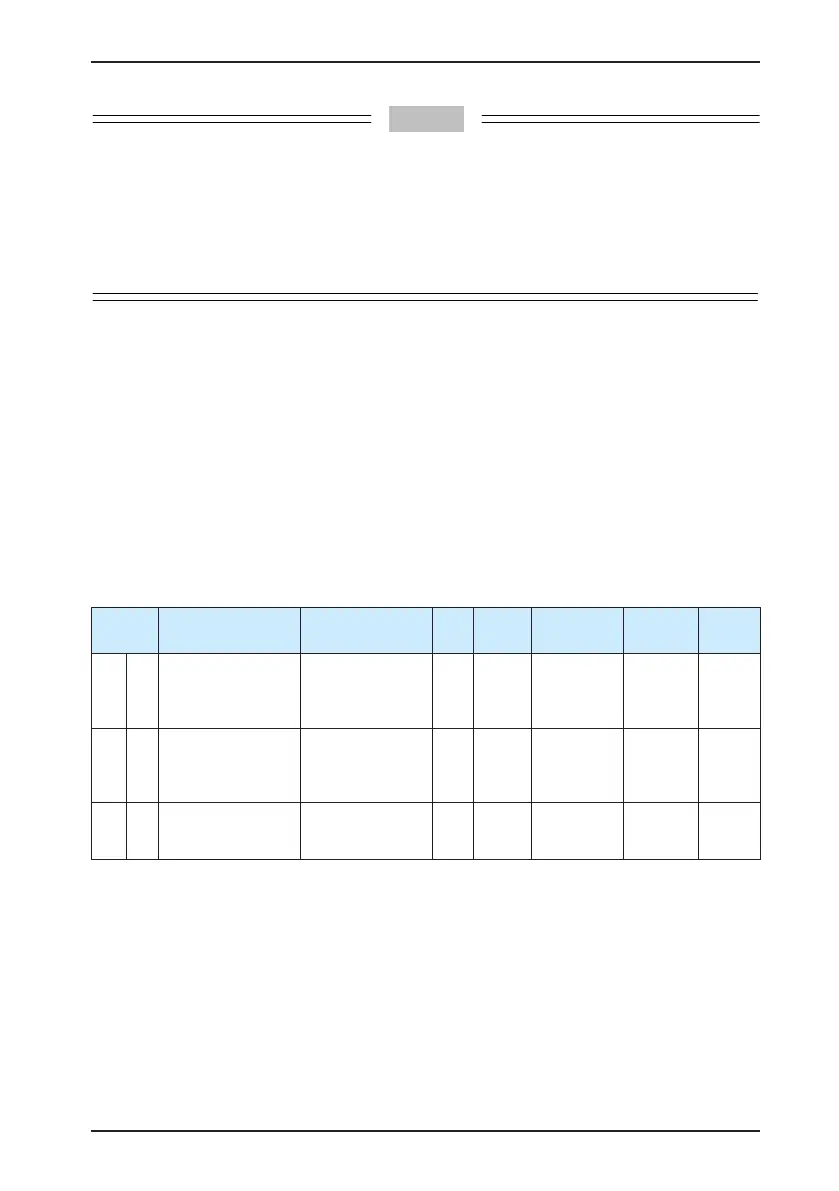

Function

Code

Parameter Name Setting Range Unit Default

Effective

Time

Property

Control

Mode

H07 00

Main torque

reference A source

0: Digital setting

(H07-03)

1: AI1

2: AI2

- 0 Immediate At stop T

H07 01

Auxiliary torque

reference B source

0: Digital setting

(H07-03)

1: AI1

2: AI2

1 Immediate At stop T

H07 03

Keypad setting

value of torque

reference

-300.0 to 300.0 % 0.0 Immediate

During

running

T

Loading...

Loading...