IS620P User Manual Chapter 6 Troubleshooting

- 131 -

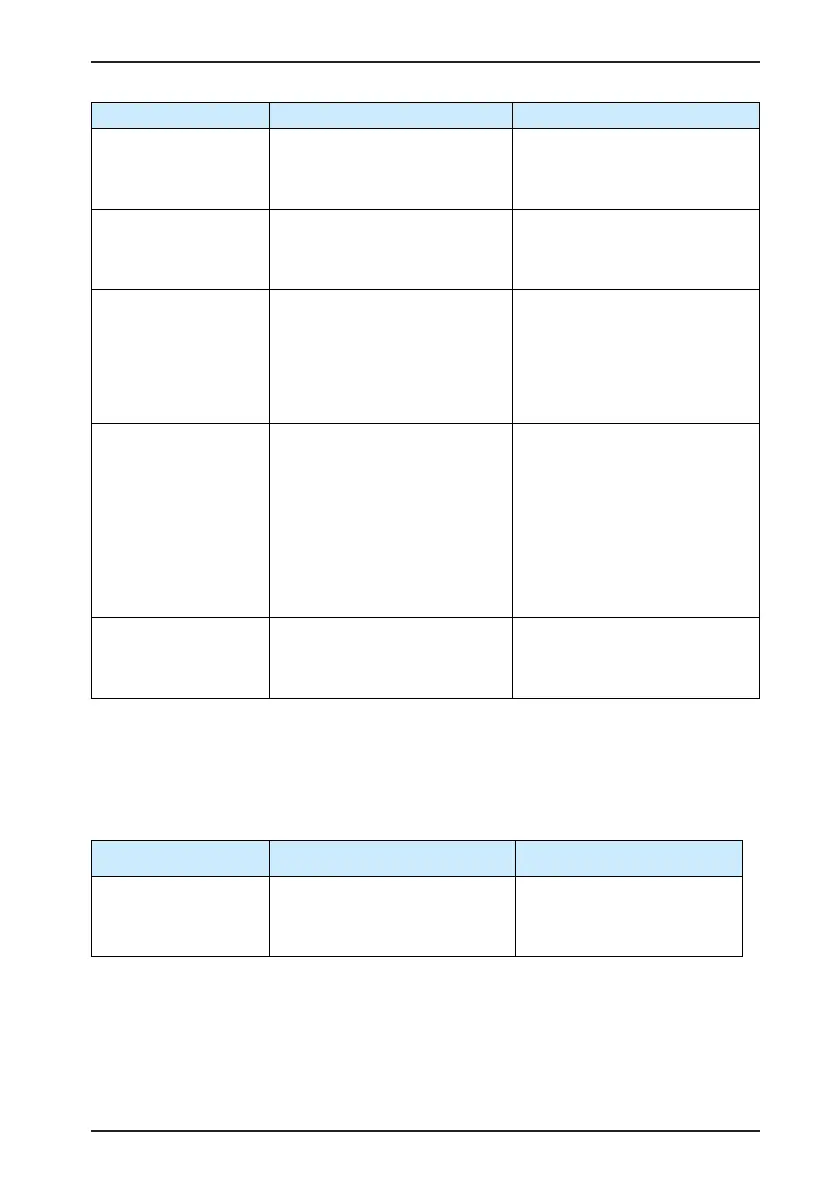

Cause Conrming Method Corrective Action

5. The motor UVW

cables are short

circuited.

•

Disconnect the motor cables

and check whether the motor

UVW cables are short circuited

and whether glitch occurs.

Connect the motor cables correctly.

6.The motor is damaged.

•

Disconnect the motor cables

and measure whether resistance

between the motor cables UVW

is balanced.

Replace the motor if the resistance

is unbalanced.

7. The gain setting is

improper and the motor

oscillates.

•

Check whether the motor

oscillates or generates a shrill

noise during motor startup

and running. You can view the

current feedback by using the

drive debugging platform of

Inovance.

Adjust the gain by referring to

chapter 4.

8. The encoder cable

is incorrectly wired,

corrosive, or connected

loosely.

•

Check whether the cable you

use is standard conguration

of Inovance and whether the

cable is aging, corrosive or is

connected loosely.

•

Set the servo enabled signal to

OFF and rotate the motor shaft

manually. Check whether H0B-

10 (rotation angle) changes as

the motor rotates.

Re-weld, fasten or replace the

encoder cable.

9. The servo drive is

faulty.

•

The fault remains after the

motor cables are disconnected

and the servo drive is powered

on again.

Replace the servo drive.

13. Er.207: Shaft D/Q current overow

Cause:

•

Abnormal current feedback results in overow of the internal register of the servo drive.

•

Abnormal encoder feedback results in overow of the internal register of the servo drive.

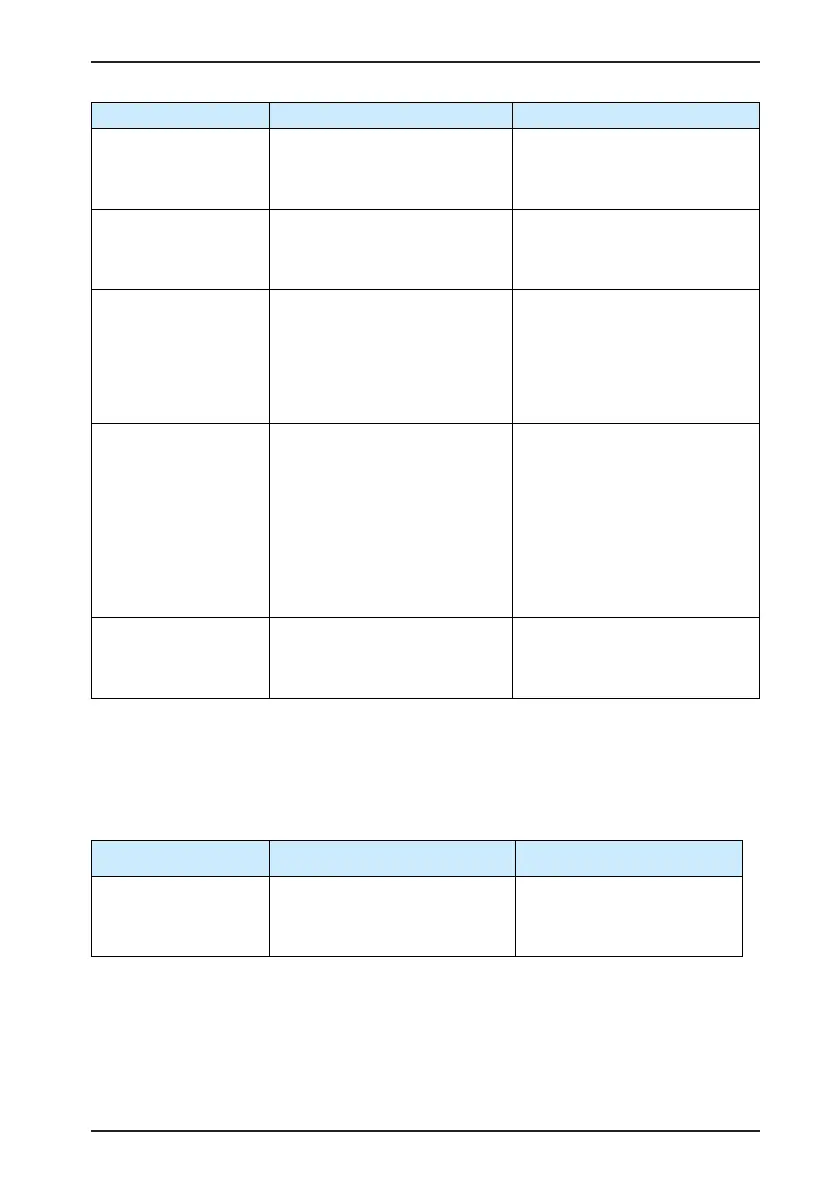

Cause Conrming Method Corrective Action

1. Shaft D/Q current

overow

•

If the fault remains after the drive

is powered off and powered on

again several times, the servo

drive is faulty.

Replace the servo drive.

Loading...

Loading...