Chapter 6 Troubleshooting IS620P User Manual

- 138 -

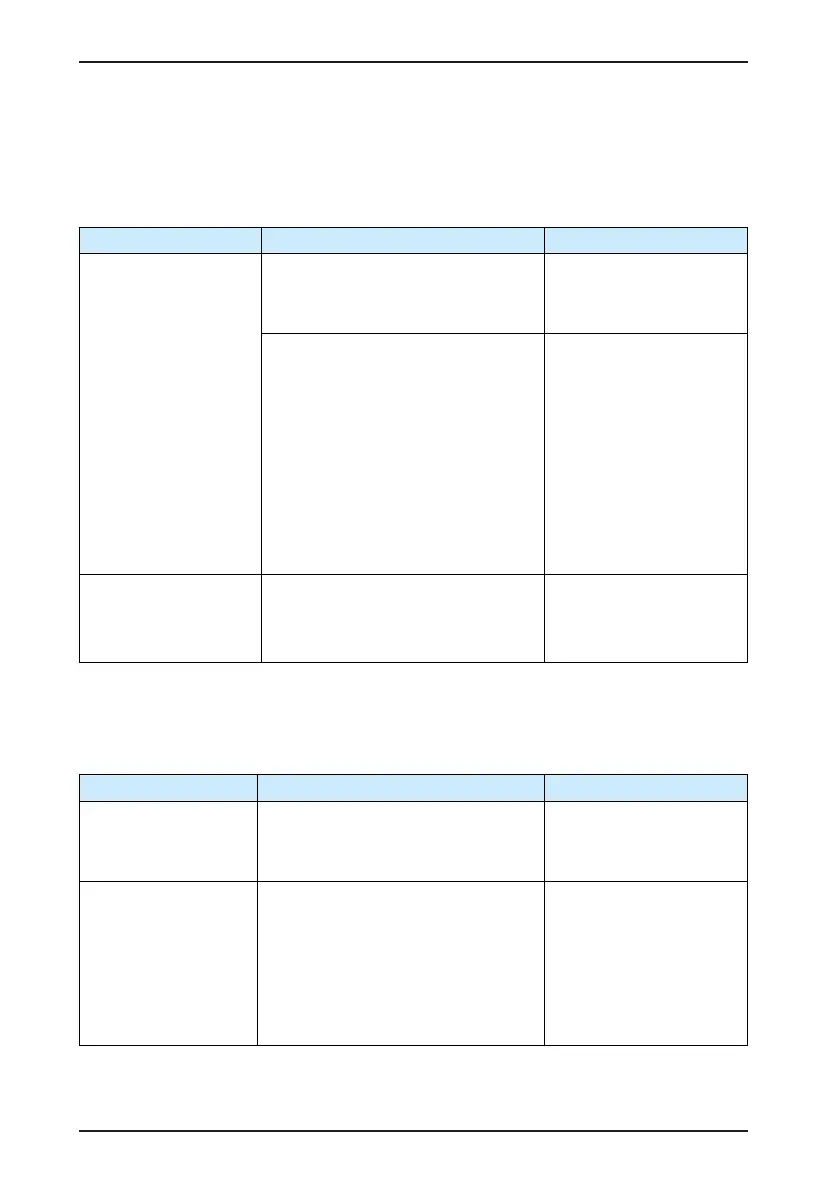

21. Er.430: Control power undervoltage

Cause:

•

220 V drive: normal value: 310 V, overvoltage level: 200 V

•

380 V drive: normal level: 540 V, overvoltage level: 380 V

Cause Conrming Method Corrective Action

1. The control power is

unstable or fails.

•

Check whether the servo drive is in

the process of cutting off the control

power (L1C, L2C) or instantaneous

power failure occurs.

Re-power on the servo drive.

If the fault is abnormal power

failure, keep power supply

stable.

•

Check whether the input voltage of

control cables satises the following

specication:

220 V drive:

Effective value: 220 to 240 V

Allowed error: -10% to 10% (198 to

264 V)

380 V drive:

Effective value: 380 to 440 V

Allowed error: -10% to 10% (342 to

484 V)

Increase the power capacity.

2. The control power

cables are in poor

contact.

•

Check whether the control cables

are well connected and whether the

voltage of the control cables satises

the preceding specication.

Re-connect it or replace the

control cables.

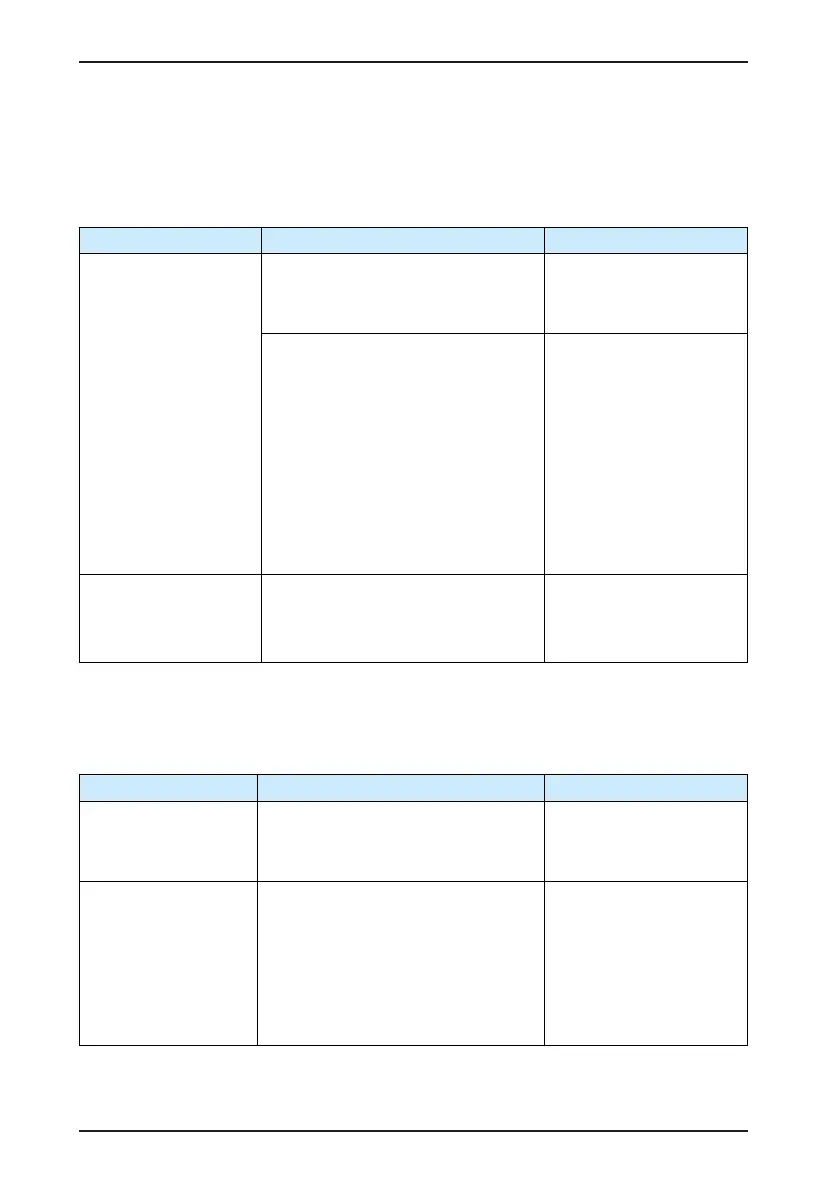

22. Er.500: Servo motor overspeed

Cause:

•

The actual speed of the servo motor exceeds the overspeed level.

Cause Conrming Method Corrective Action

1.The UVW phase

sequence is incorrect.

•

Check whether the UVW phase

sequence on the servo drive side is

consistent with that on the motor side.

Connect the UVW cables

according to the correct

phase sequence.

2. The setting of H0A-08

is incorrect.

•

Check whether the overspeed level

is smaller the actual maximum motor

speed.

Overspeed level = 1.2 times of

maximum motor speed (H0A-08 = 0)

Overspeed level = H0A-08 (H0A-08 ≠

0, and H0A-08 < 1.2 times of maximum

motor speed)

Reset the overspeed

level according to actual

mechanical requirement.

Loading...

Loading...