IS620P User Manual Chapter 4 Running and Commissioning

- 91 -

4.3 Use of the Torque Control Mode

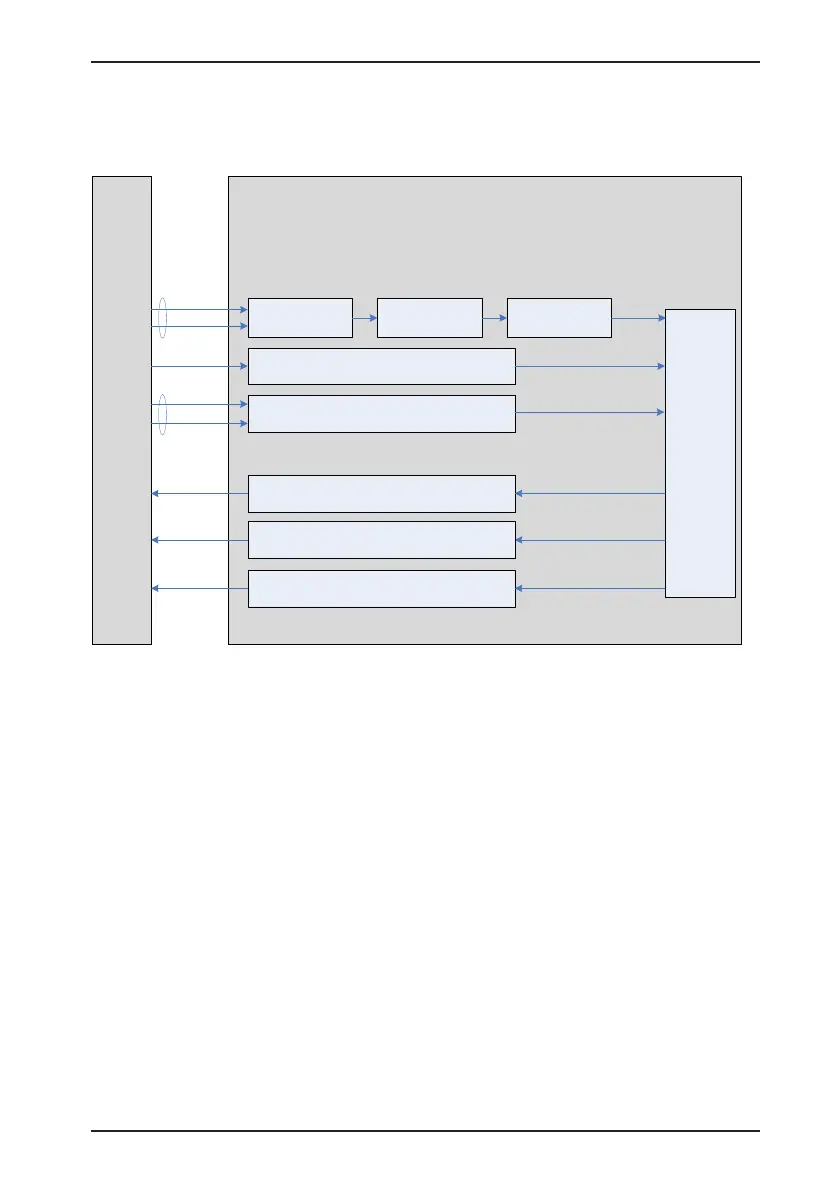

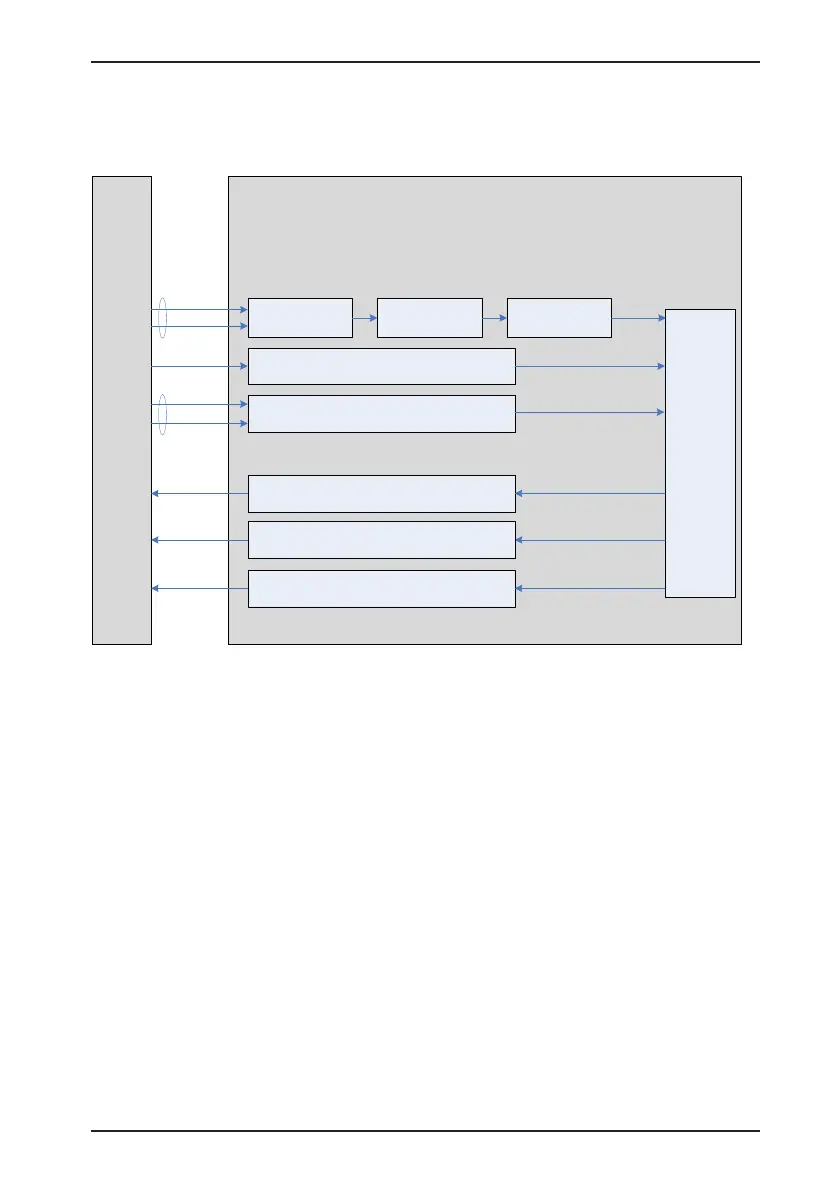

Figure 4-12 Diagram of the torque control mode

Reference input

setting

Speed

regulator

Host

controller

Torque

reference

input

H07-00 Main torque

reference A source

H07-01 Auxiliary torque

reference B source

H07-02 Torque

reference source

H07-05 Torque

reference filter time

constant 1

Reference filter Reference limit

Reference direction selection

SPDDirSel

input

Torque limit

Servo drive

H07-07 Torque limit source

H07-08 T-LMT selection

H07-09 Internal forward torque limit

H07-10 Internal reverse torque limit

H07-11 External forward torque limit

H07-12 External reverse torque limit

H07-17 Speed limit source

H07-18 V-LMT selection

H07-19 Forward speed limit/

Speed limit 1 in torque control

H07-

20 Reverse speed limit/

Speed limit 2 in torque control

Speed limit function

V-LT output

Torque limit output

C-LT output

Toq-Reach

output

Torque reached output

H07-21 Base value for torque reached

H07-22 Threshold of torque reached valid

H07-23 Threshold of torque reached invalid

External AI

speed limit

input

The main use procedure of the torque control mode is as follows:

1. Connect the power cables of the main circuit and control circuit of the servo drive, motor

power cables, and encoder cables correctly. After power-on, the keypad of the servo drive

displays "rdy", indicating that the wiring is correct.

2. Perform trial jog running by pressing keys and ensure that the motor can run properly.

3. Connect the required DI/DO signals and analog speed references of terminal CN1

according to Figure 4-13.

4. Perform the setting related to the torque control mode.

5. Set a low speed limit, send a forward or reverse torque reference, and check whether the

rotating direction of the motor is correct and whether the torque is correctly limited. If yes,

the servo system can be used properly.

Loading...

Loading...