Chapter 6 Troubleshooting IS620P User Manual

- 130 -

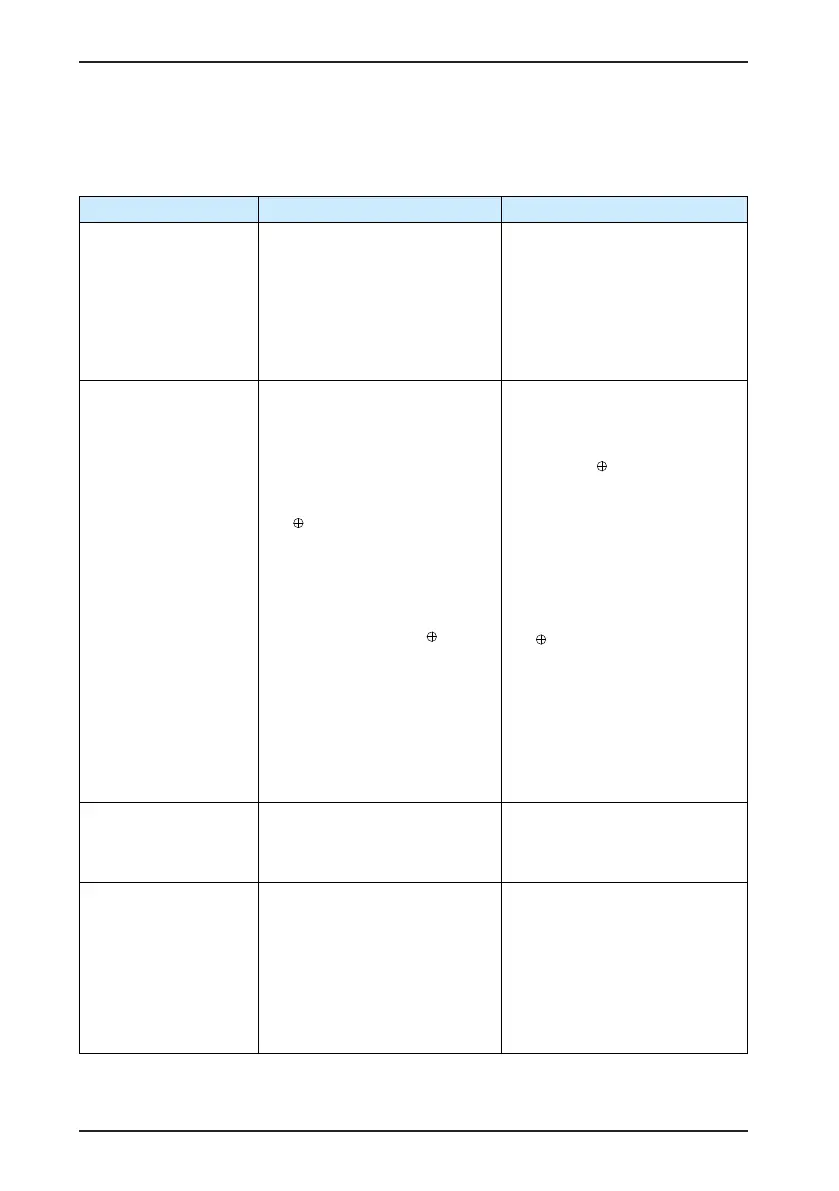

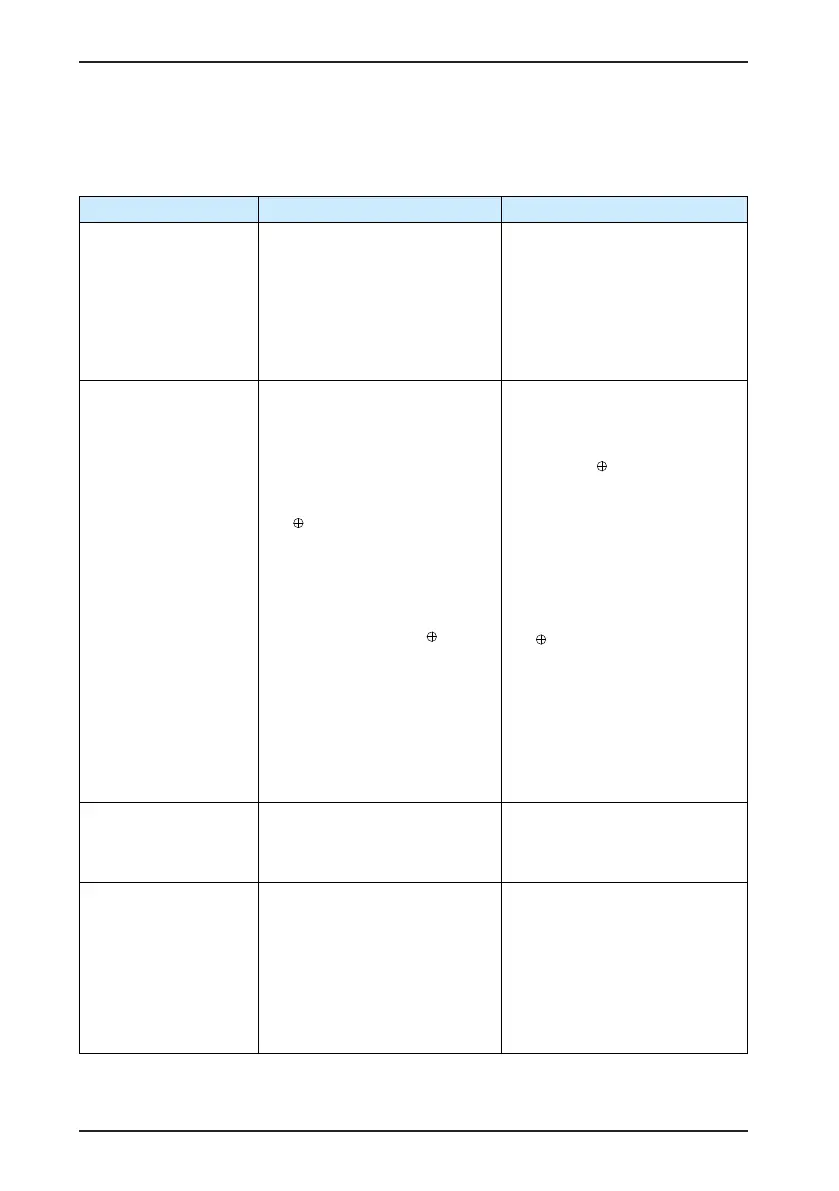

12. Er.201: Overcurrent 2

Cause:

•

The servo drive detects overcurrent on hardware.

Cause Conrming Method Corrective Action

1. The reference is input

and the servo drive is

started simultaneously.

Or the reference is input

too early.

•

Check whether the reference is

input before the operation panel

displays "Rdy".

•

Normally, after the operation

panel displays "Rdy", set the

servo enabled signal (S-ON) to

ON and then input the reference.

•

If allowed, add the reference

lter time constant or increase

the acceleration/deceleration

time.

2. The regen resistor

is too small or short

circuited.

•

If internal regen resistor is used

(H02-25 = 0), check whether

P and D are connected with

a cable reliably. If yes, measure

the resistance between C and

D.

•

If external regen resistor is used

(H02-25 = 1/2), measure the

resistance between P and C.

•

For the regen resistor

specication, refer to section 1.4

Regen Resistor Specications..

•

If internal regen resistor is used

and the resistance is 0, use

external regen resistor (H02-

25 = 1/2) and remove the cable

between P and D.

•

Select the external regen resistor

of the same resistance and

power as internal regen resistor.

•

If external regen resistor is used

and the resistance is smaller

than H02-21 (allowed minimum

value of regen resistor), connect

a new regen resistor between

P and C by referring the regen

resistor specication in section

1.4.

•

Make H02-26 (power of external

regen resistor) and H02-27

(resistance of external regen

resistor) consistent with the

used external regen resistor

specication.

3. The motor cables are

in poor contact.

•

Check whether the power

cables of the servo drive and

the motor UVW cables are

loose.

Fasten the cables that become

loose or are disconnected.

4. The motor cables are

grounded.

•

After ensure the power cables

of the servo drive and the

motor cables are connected

securely, measure the insulation

resistance between the UVW of

the servo drive and the ground

cable (PE) and check whether

the insulation resistance is MΩ-

level.

Replace the motor if the insulation

is poor.

Loading...

Loading...