11

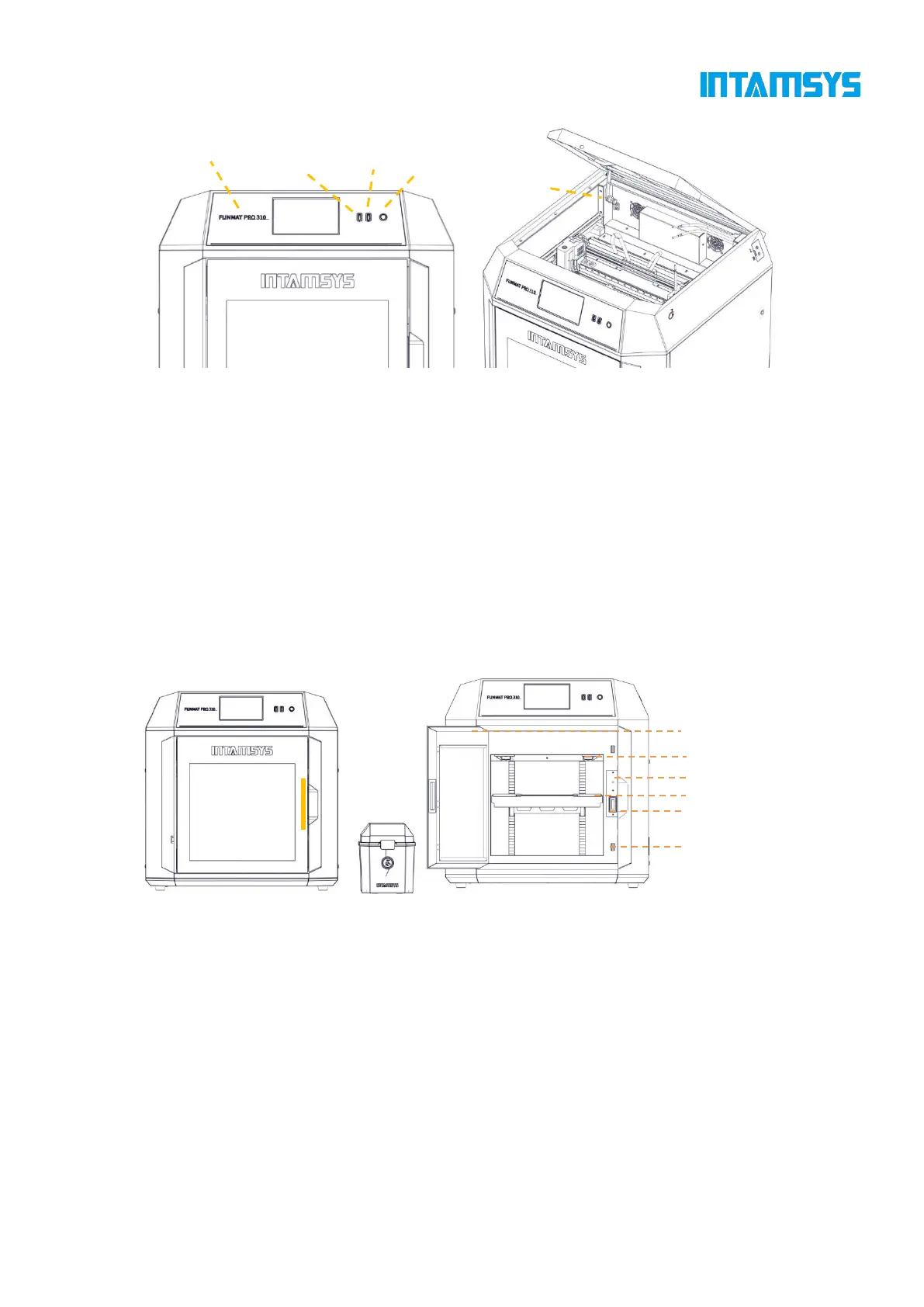

Fig. 3.3 Schematic Diagram of Top Door Opening Fig. 3.4 Schematic Diagram of User Operation Area

3.3 Printing Chamber Components

The front door can be pulled open from the right side by the release of the electromagnetic suction

of the front door through screen operation, and then it can be seen that the printing chamber contains

front door, hot bed, double extruder assembly, electromagnetic suction, magnetic suction and door

sensor.

When the printing chamber is heated, its stainless steel build plate and side plates are hot. Please do

not touch them to avoid scalding.

The four leveling knobs under the hot bed are used to manually level the printing platform.

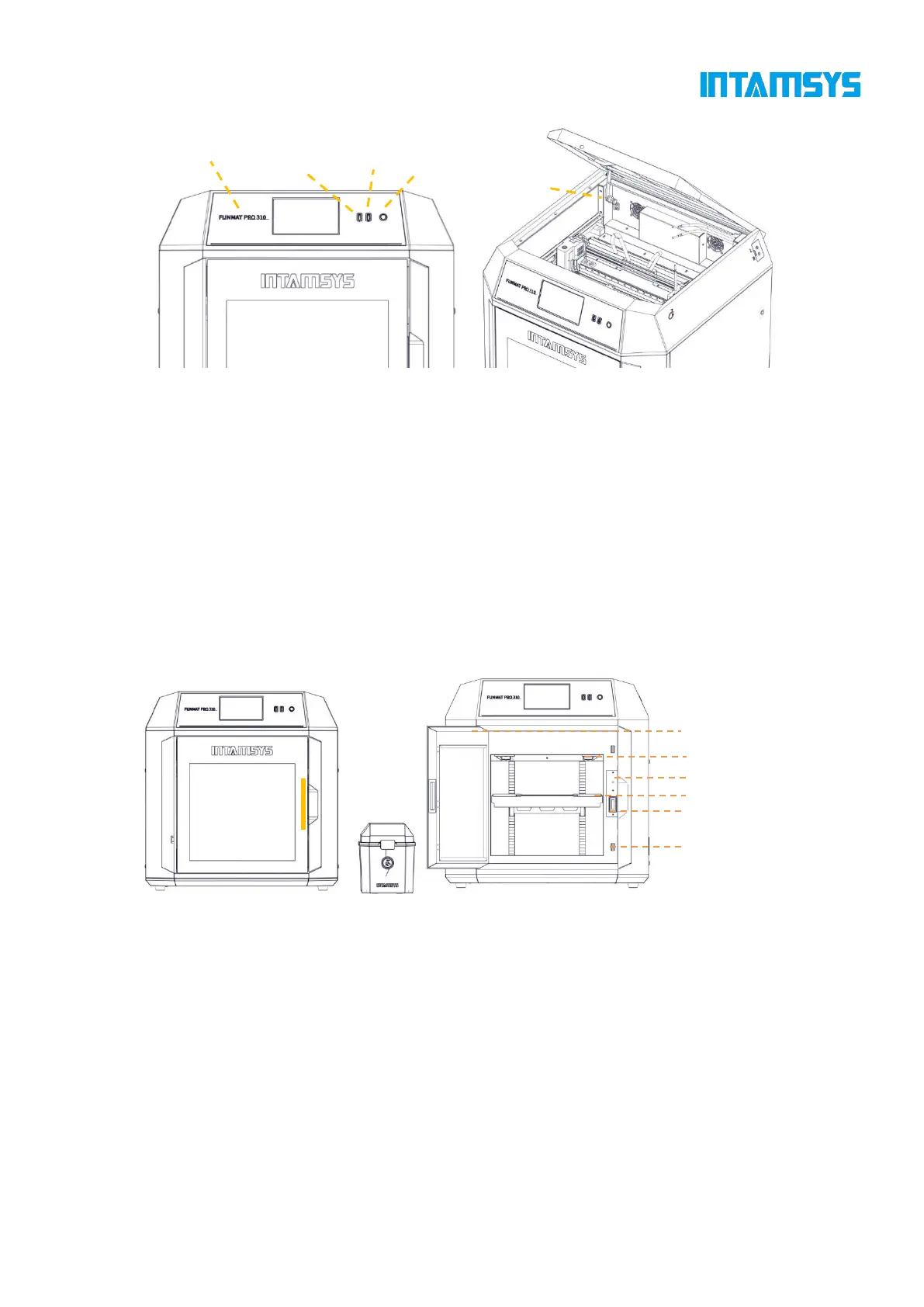

Fig. 3.5 Schematic Diagram of Front Door Opening Mode Fig.3.6 Printing Chamber

3.4 Independent Filament Box

The printer is supplied with an external INTAMBox Sealed Drying Filament box that can hold up

to two rolls of 1 kg material. Seal rings and buckles are provided around the filament box to ensure

its sealing performance. The filament box is supplied with a drying box filled with 4A molecular

sieve desiccant, which can ensure the low humidity environment inside the filament box. The upper

cover of the filament box is equipped with a charging tray tension device to ensure that the printing

wire rod will not be loosen during printing and that the wire coil will not topple when the wire rod

Loading...

Loading...