68

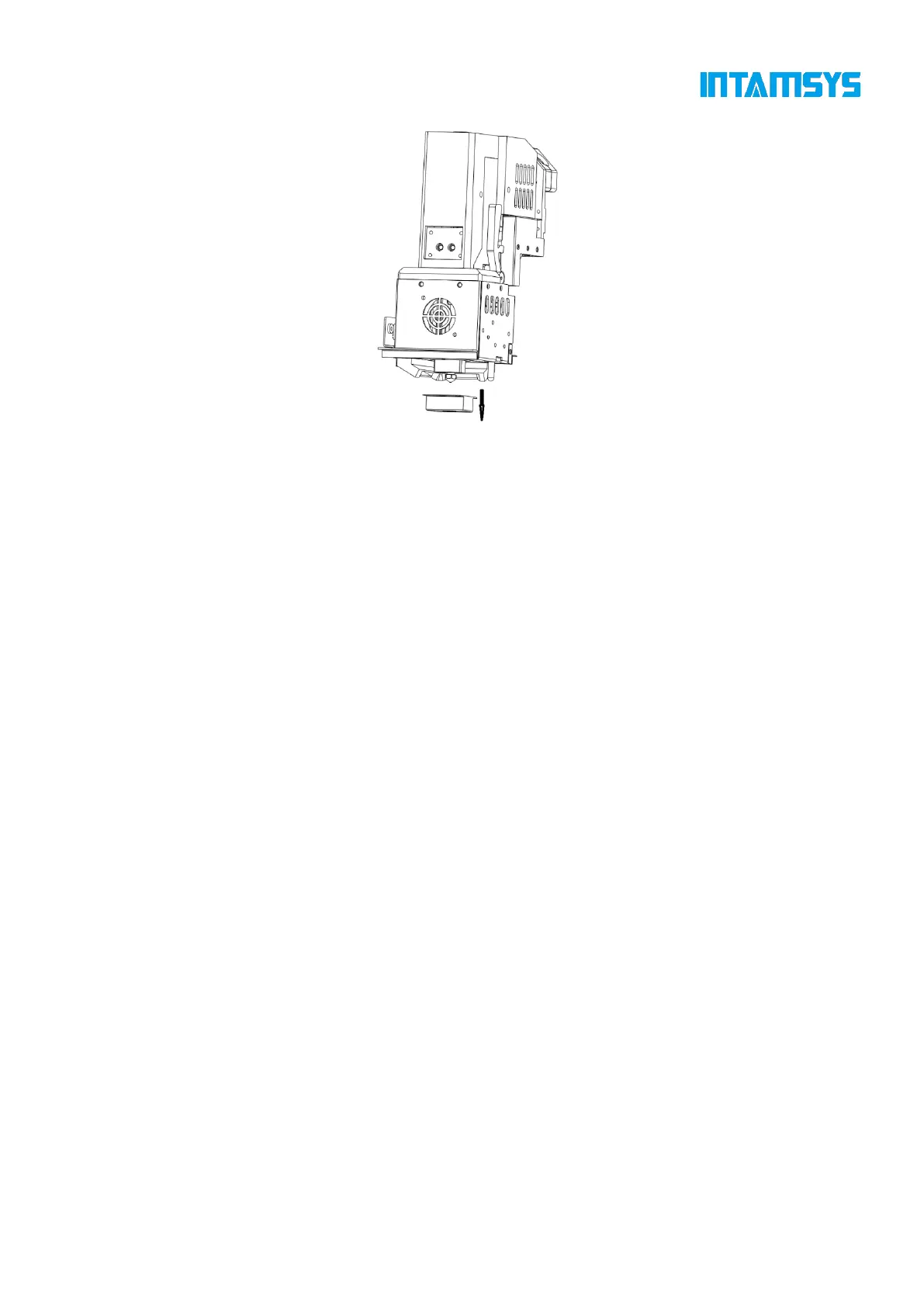

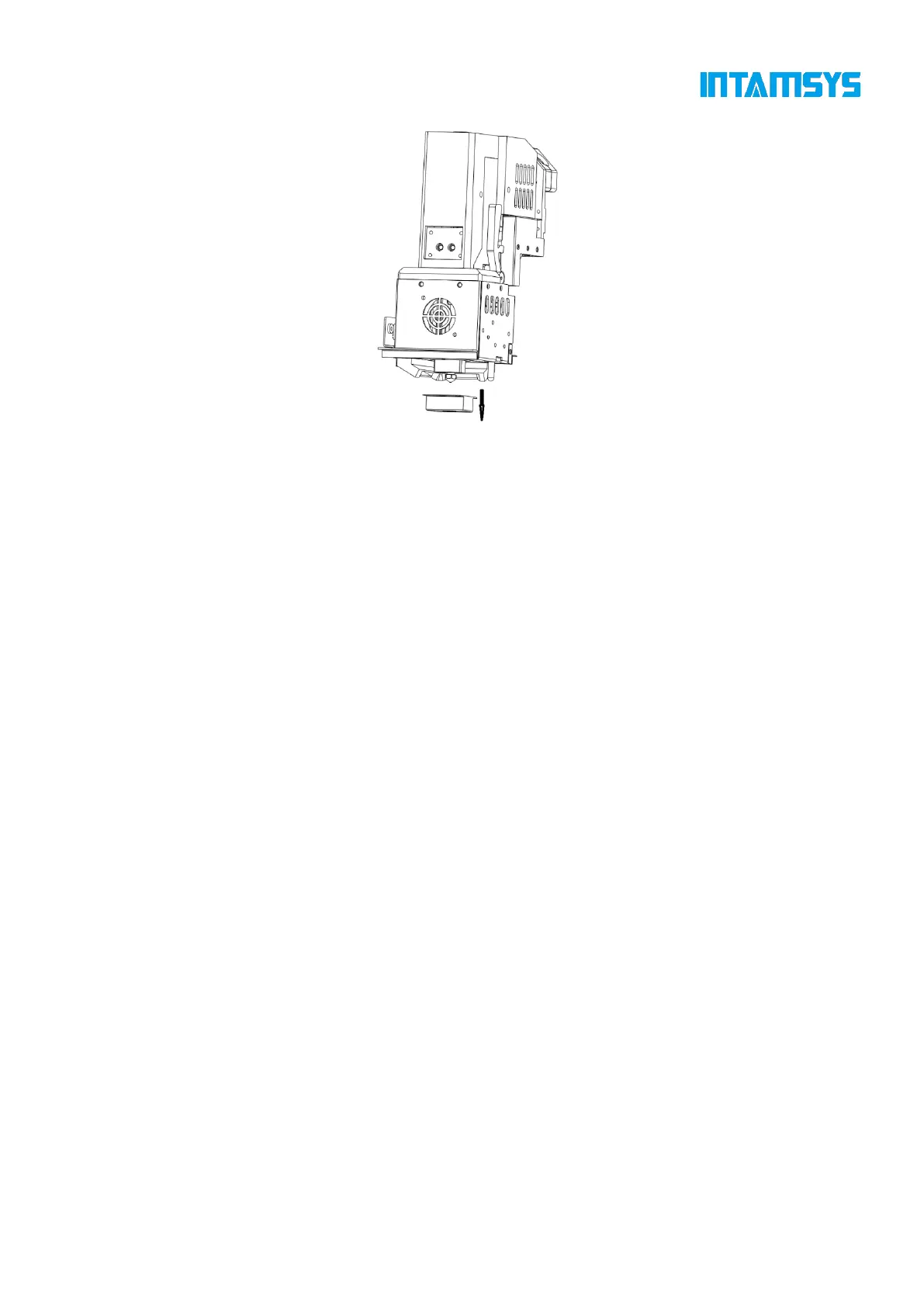

Fig. 6.1 Clean the Nozzle

6.2 Maintenance after Each Printing

6.2.1 Clean the printing build plate

After printing, lower the printing platform for a certain distance, then wear gloves to take out the

printing build plate together with the print part from the printer, bend the flexible printing build plate

with both hands to separate the print part from the printing build plate, and then clean the printing

build plate and put it back on the hot bed.

6.2.2 Clean the nozzle

Inspect whether the nozzle surface is stuck with some print materials after each printing. If the

nozzle is covered by residual materials for a long time, its service life will be affected. To prepare

for the next printing, pay special attention to cleanliness of the nozzle surface. If the nozzle is stuck

with too many residual materials, heat the nozzle to the set temperature of the material and then

clean it using a copper wire brush with wooden handle.

Note: Move the printing build plate to the lowest position before cleaning the nozzle, and be careful

to avoid scalding due to high temperature of the nozzle during cleaning.

6.2.3 Clean the chamber

The nozzle brush scrapes some material chips into the chamber during printing. Clean the chamber

carefully every time after printing a work.

6.3 Regular Maintenance

6.3.1 Clean feeding gears of the extruder

After long-term use, more and more cut material chips accumulate in the tooth spaces of feeding

gears, thus reducing the feeding force of the extruder. It is recommended to remove the front housing

Loading...

Loading...