69

of the extruder every month, remove the front cover plate, and take out the feeding gear shaft 2 to

inspect the accumulation of material chips in the tooth spaces of two feeding gear shafts. If necessary,

you need to carefully clean each tooth space with tools such as small copper wire brush or tweezers.

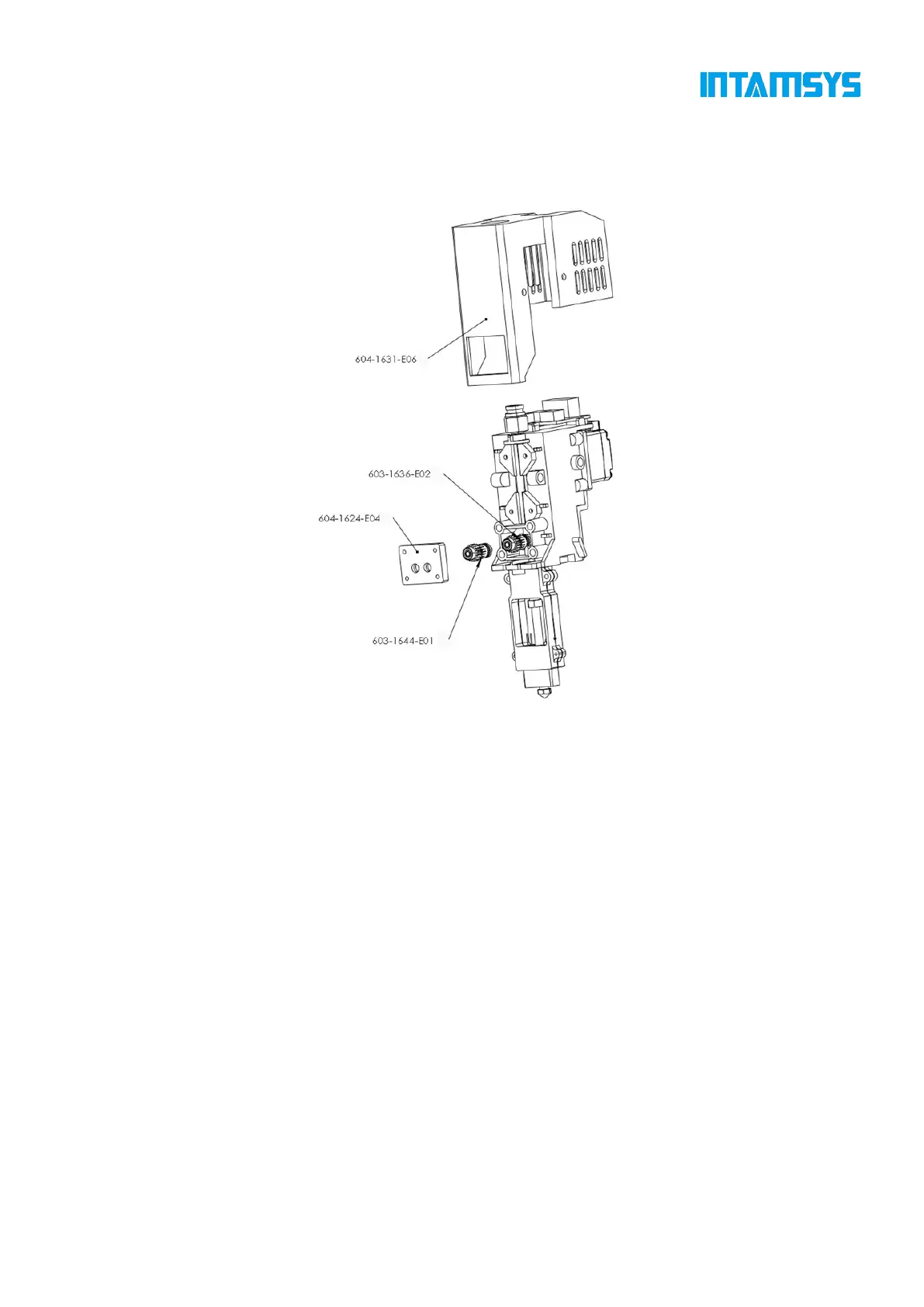

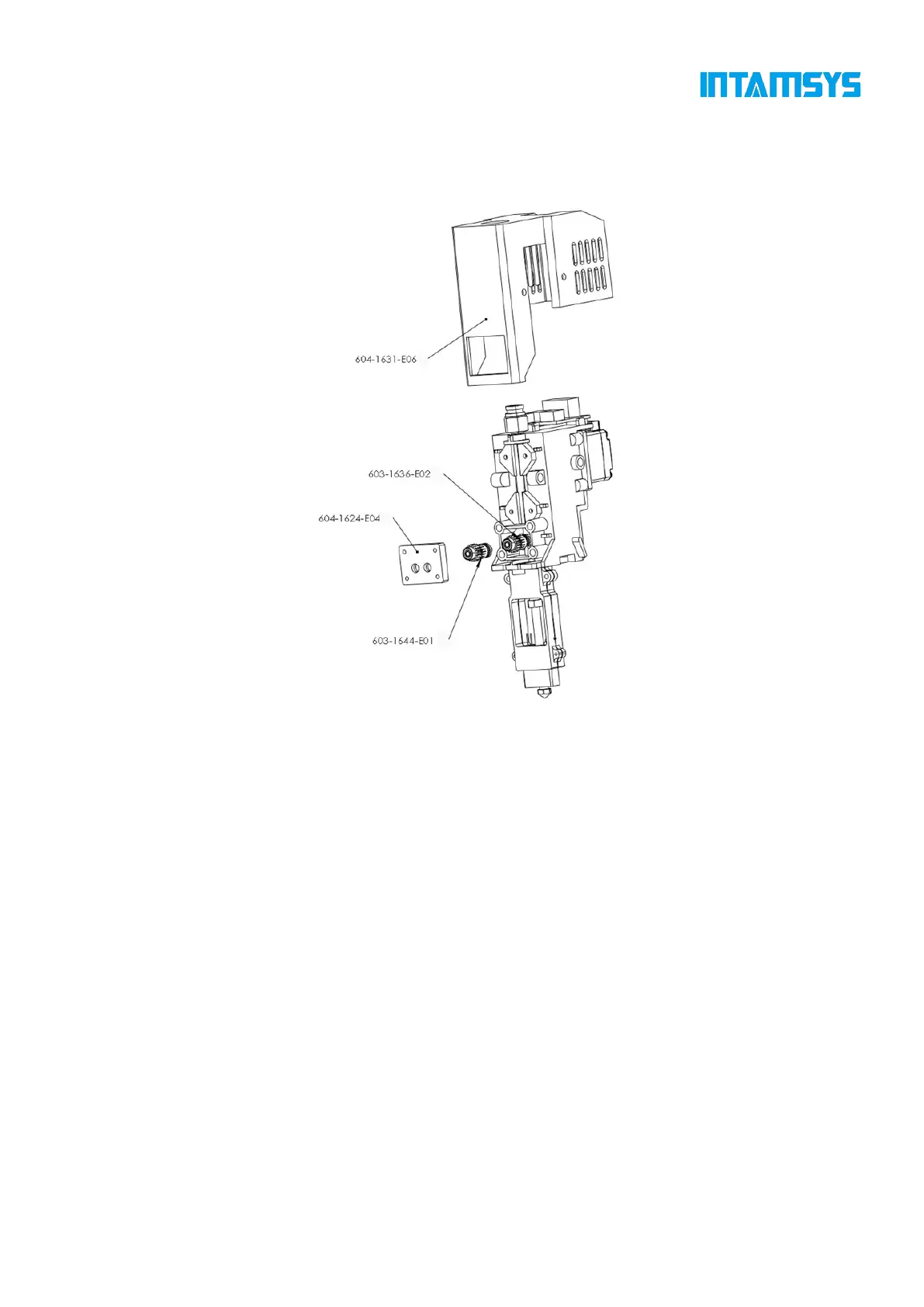

Fig. 6.2 Position of Feeding Gear

6.3.2 Maintenance of moving parts

It is recommended to re-apply PFPE grease or lithium soap based grease every 6 months for the X-

axis and Y-axis motion guide components (The left and right lateral plates of the printer shall be

removed when applying grease to the Y-axis guide rail).

1. Ensure that all relevant temperatures are set to "0" and the motor is disabled in System

Settings ("Motor enabled" is Off);

2. Manually move the extruder assembly to the center;

3. Clean the residual grease on the X/Y guide rail with a cloth;

4. Apply Perfluoropolyether grease to the X/Y guide rail with a soft brush. Note: Excessive

grease may have a negative impact on motion.

5. Move the extruder assembly back and forth several times on the X/Y axis for evenly

applying the grease.

Loading...

Loading...