71

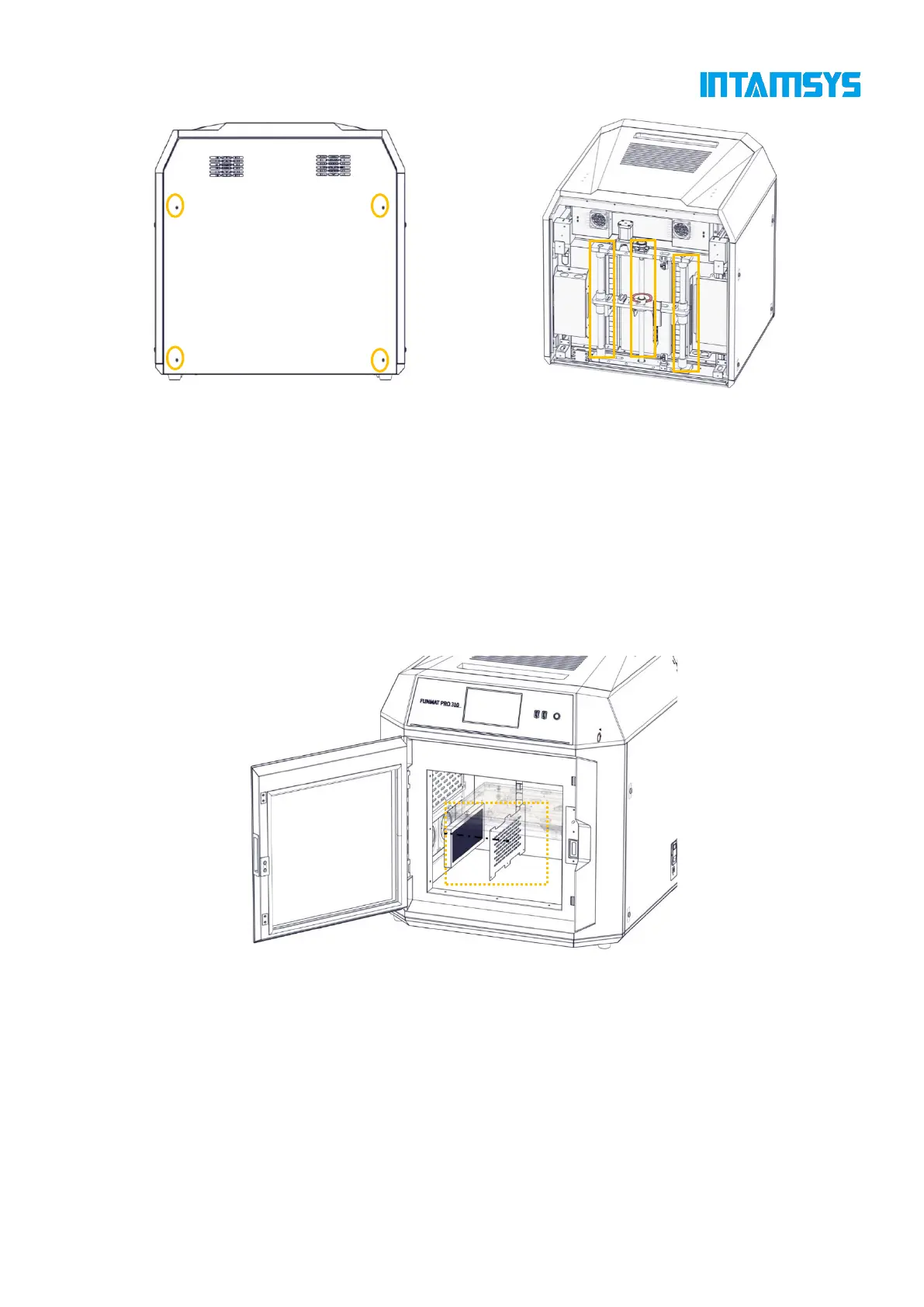

Fig. 6.4 Lubrication and Maintenance of Z Axis Linear Guide Rails

Note: Before re-applying grease on each component, wipe the surface of the kinematic pair clean

with a dust-free cloth dipped in alcohol, then evenly apply grease on the surface.

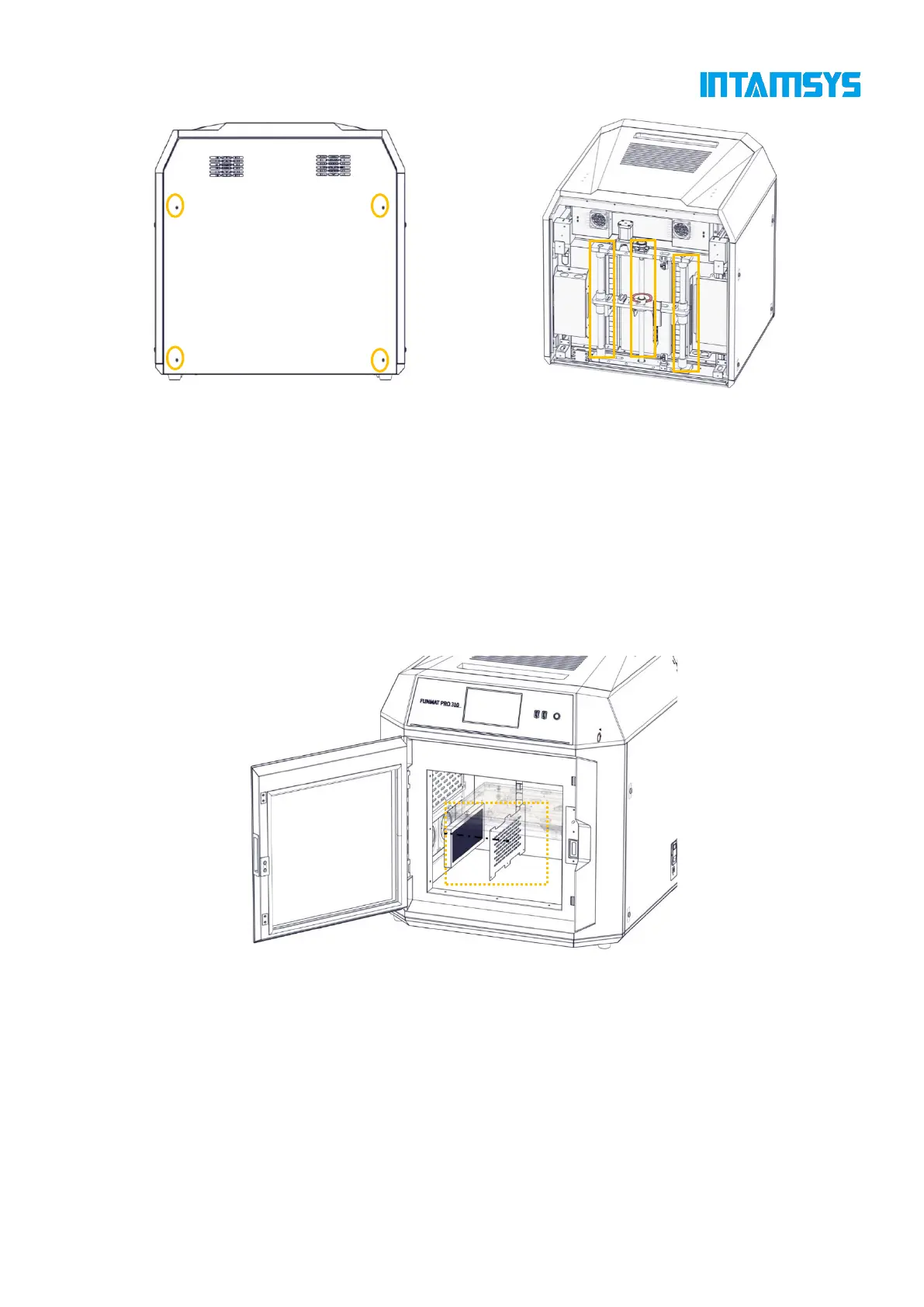

6.3.3 Maintenance of chamber filter

Air filters are installed at the air inlets on both sides of the printing chamber. You can access the

filters by unscrewing the screws of the filter cover plate and removing the cover plate. It is

recommended to check or replace them every 6 months.

Fig. 6.5 Cleaning of Chamber Filter

6.3.4 Maintenance and Replacement of Feeding Pipe

The feeding pipe of the printer consists of two parts, one inside the printer and the other outside the

printer. The external feeding pipe is connected to the printer from an independent filament box, and

the internal feeding pipe is connected to the extruder by a material shortage detection mechanism.

As the internal feeding pipe works in a high-temperature environment, it is recommended to replace

it every 12 months to avoid possible aging that may reduce its flexibility.

Loading...

Loading...