SECTION 4 - HYDRAULICS

4-14 – JLG Lift – 3121166

1. Using suitable protection, clamp the cylinder rod in

a vise or similar holding fixture as close to piston as

possible.

2. Carefully thread the piston on the cylinder rod hand

tight, ensuring that the o-ring and back-up rings are

not damaged or dislodged.

3. Thread the piston onto the rod until it abuts the

spacer end and install the tapered bushing.

NOTE: When installing the tapered bushing, piston and mat-

ing end of rod must be free of oil.

4. Assemble the tapered bushing loosely into the pis-

ton and insert JLG capscrews (not vendor cap-

screws) through the drilled holes in the bushing and

into the tapped holes in the piston.

5. Tighten the capscrews evenly and progressively in

rotation to the specified torque value.

6. After the screws have been torqued, tap the tapered

bushing with a hammer (16 to 24 oz.) and brass

shaft (approximately 3/4" in diameter) as follows;

a. Place the shaft against the cylinder rod and in

contact with the bushing in the spaces between

the capscrews.

b. Tap each space once; this means the tapered

bushing is tapped 3 times as there are 3 spaces

between the capscrews.

7. Retorque the capscrews evenly and progressively in

rotation to the specified torque value.

8. Remove the cylinder rod from the holding fixture.

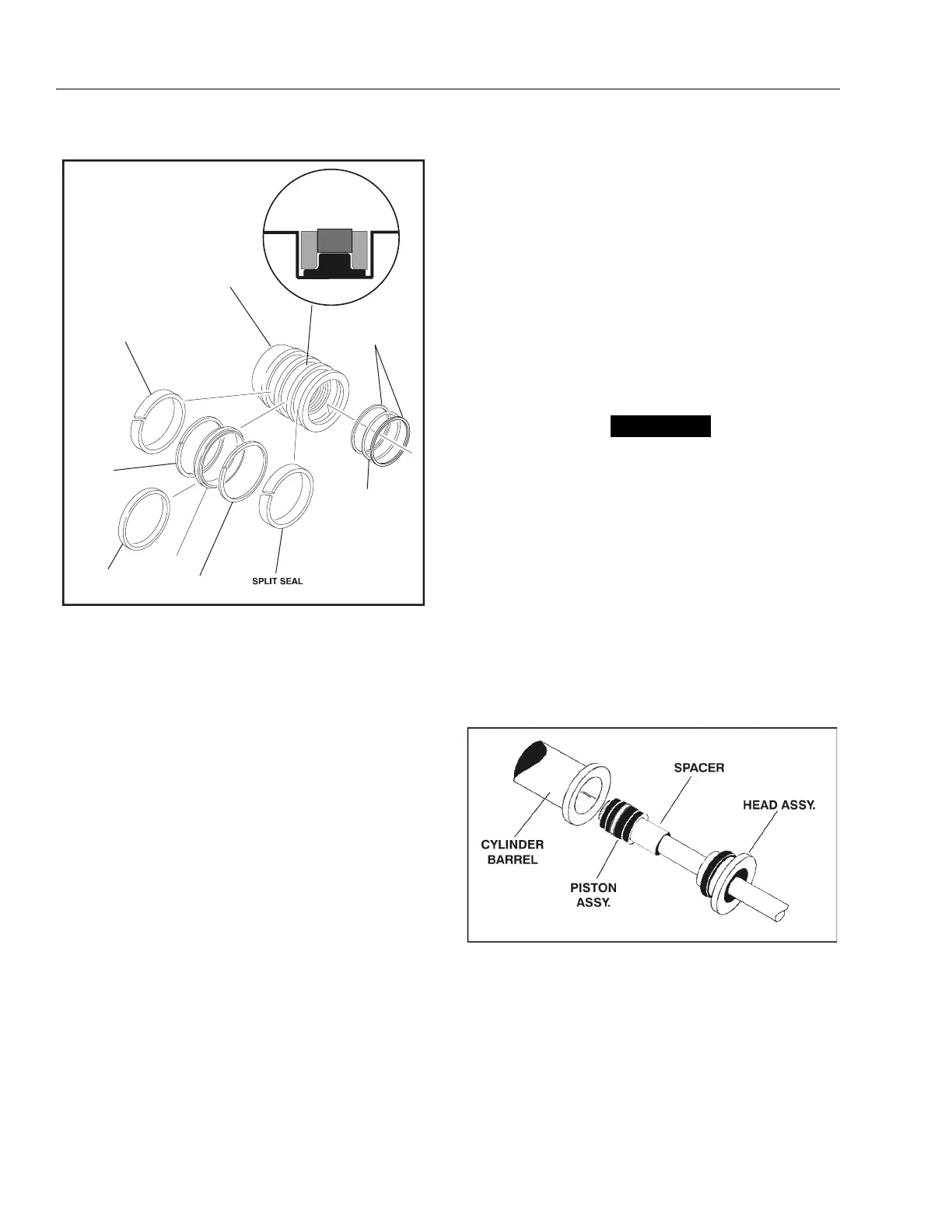

9. Place new guide locks and seals in the applicable

outside diameter grooves of the cylinder piston.

(See Figure 4-10.)

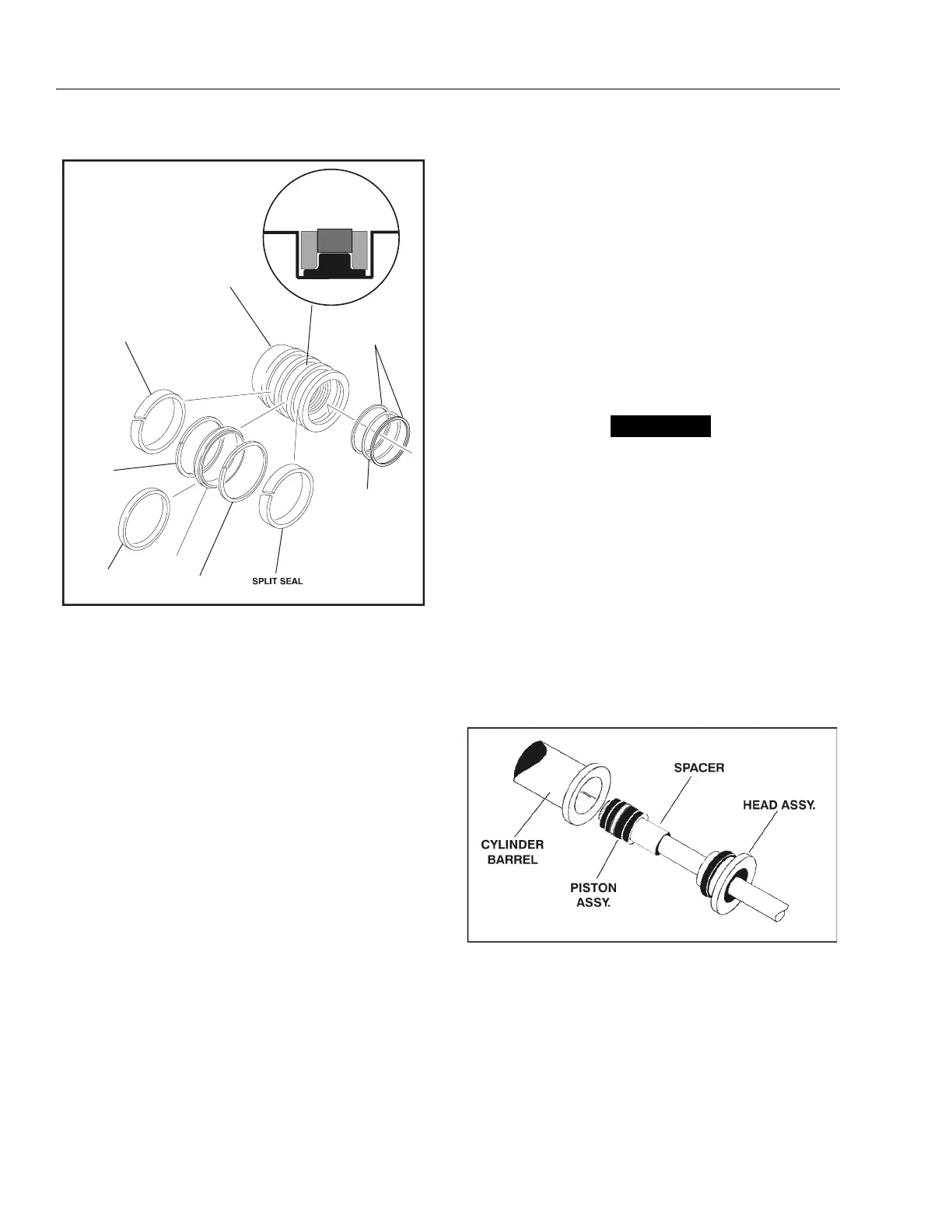

10. Position the cylinder barrel in a suitable holding fix-

ture.

EXTREME CARE SHOULD BE TAKEN WHEN INSTALLING THE

CYLINDER ROD, HEAD, AND PISTON. AVOID PULLING THE ROD

OFF-CENTER, WHICH COULD CAUSE DAMAGE TO THE PISTON

AND CYLINDER BARREL SURFACES.

11. With the barrel clamped securely, and while ade-

quately supporting the rod, insert the piston end into

the barrel cylinder. Ensure that the piston loading o-

ring and seal ring are not damaged or dislodged.

12. Continue pushing the rod into the barrel until the cyl-

inder head gland can be inserted into the barrel cyl-

inder.

13. Secure the cylinder head gland using the washer

ring and socket head bolts.

14. After the cylinder has been reassembled, the rod

should be pushed all the way in (fully retracted) prior

to the reinstallation of any holding valve or valves.

15. If applicable, install the cartridge-type holding valve

and fittings in the rod port block, using new o-rings

as applicable. (See Table 4-3, Holding Valve Torque

Specifications).

BACKUP

RINGS

O-RING

PISTON

SPLIT SEAL

SEAL

SPLIT BACKUP RING

T - RING

SPLIT

BACKUP

RING

Figure 4-10. Piston Seal Kit Installation

Figure 4-11. Rod Assembly Installation

Loading...

Loading...