SECTION 1 - SPECIFICATIONS

1-6 – JLG Lift – 3121166

1.2 TORQUE REQUIREMENTS

Self locking fasteners, such as nylon insert and thread

deforming locknuts, are not intended to be reinstalled

after removal. Always use new replacement hardware

when installing locking fasteners..

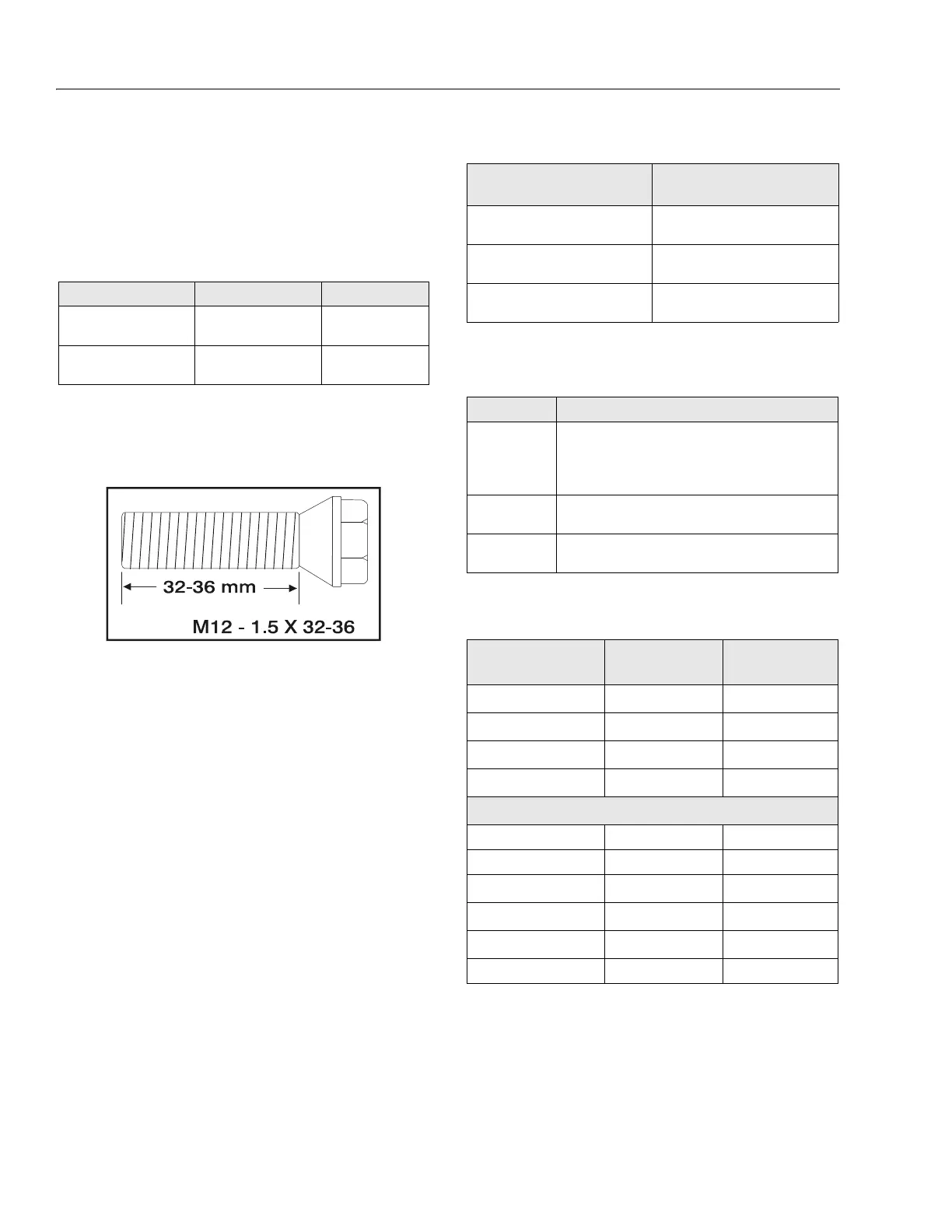

NOTE: Anytime a wheel bolt is replaced, be sure one of the

same length is used. Use bolt shown below on

wheels that use the 1/4" (6.4mm) ring.

NOTE: After tightening the spindle nut to the proper torque,

loosen completely until you can turn by hand. Finger

tighten nut by hand without rotating hub. Install cotter

pin by backing nut off, if necessary, in order to line up

slot.

When maintenance becomes necessary or a fas-

tener has loosened, refer to Section 1.8, Torque

ChartS to determine proper torque value.

1.3 LUBRICATION

Hydraulic Oil

NOTE: Hydraulic oils must have anti-wear qualities at least

to API Service Classification GL-3, and sufficient

chemical stability for mobile hydraulic system ser-

vice. JLG Industries recommends DTE 11M hydrau-

lic oil.

Aside from JLG recommendations, it is not advisable

to mix oils of different brands or types, as they may

not contain the same required additives or be of

comparable viscosities. If use of hydraulic oil other

than DTE 11M is desired, contact JLG Industries for

proper recommendations.

Table 1-8. Torque Requirements

Description Torque Value (Dry) Interval Hours

Rear Wheel Spindle Nut

30-40 ft lb

(40-54 Nm)

50

Wheel Bolts

105 -120 ft lb

(142-163 Nm)

50

Table 1-9. Hydraulic Oil

Hydraulic System Operating

Temperature Range

SAE Viscosity Grade

0°F to +23°F

(-18°C to -5°C)

10W

0°F to 210°F

(-18°C to + 99°C)

10W-20, 10W-30

50°F to 210°F

(+10°C to +210°C)

20W-20

Table 1-10. Lubrication Specifications

Key Specifications

MPG

Multipurpose Grease having a minimum dripping

point of 350°F. Excellent water resistance and adhe-

sive qualities, and being of extreme pressure type.

(Timken OK 40 pounds minimum.)

EPGL

Extreme Pressure Gear Lube (oil) meeting API service

classification GL-5 or MIL-Spec MIL-L-2105.

HO

Hydraulic Oil. API service classification GL-3,e.g.

DTE 11M.

Table 1-11. Hydraulic Oil Specifications (Standard)

SPECIFICATION MOBIL DTE 11M

MOBIL EAL

ENVIRONSYN 32

ISO Viscosity Grade #15 #32

Gravity API 31.9 —

Pour Point, Max -40°F (-40°C) -59°F (-51°C)

Flash Point, Min. 330°F (166°C) 514°F (268°C)

VISCOSITY SPECIFICATIONS

at 40°C 15 cSt 33.1 cSt

at 100°C 4.1 cSt 6.36 cSt

at 100°F 80 SUS

—

at 210°F 43 SUS

—

cp at -30°F 3.200

—

Viscosity Index 140 147

Loading...

Loading...