SECTION 3 - CHASSIS & SCISSOR ARMS

3121166 – JLG Lift – 3-35

8. Remove manual release screws from brake assem-

bly. Apply new Gasket (12) and affix brake cover to

motor using the 2 manual release screws.

9. Attach terminal cover to the commutator end head

using two terminal cover screws.

10. Slide the strain relief of the wire harness into the slot

of the terminal cover. Align cover plate with groove in

frame and field and affix using two cover plate

screws.

Drive Motor Servicing Guidelines

Because the operating environment of industrial equip-

ment varies widely, the following are suggested for peri-

odic maintenance inspection intervals.

• Normal Service – Perform routine inspection (outlined

in the Drive Motor Inspection and Service portion of

this section) every 1,000 hours of drive time.

• Severe Service – Perform routine inspection every 500

hours of drive time. Severe service environments are

listed below:

a. Dusty or dirty locations like cement plants, lum-

ber and flour mills, coal mining, stone quarries,

etc.

b. High temperature areas like steel mills, found-

ries, etc.

c. Environments with sudden temperature change,

such as in refrigeration plant, etc.

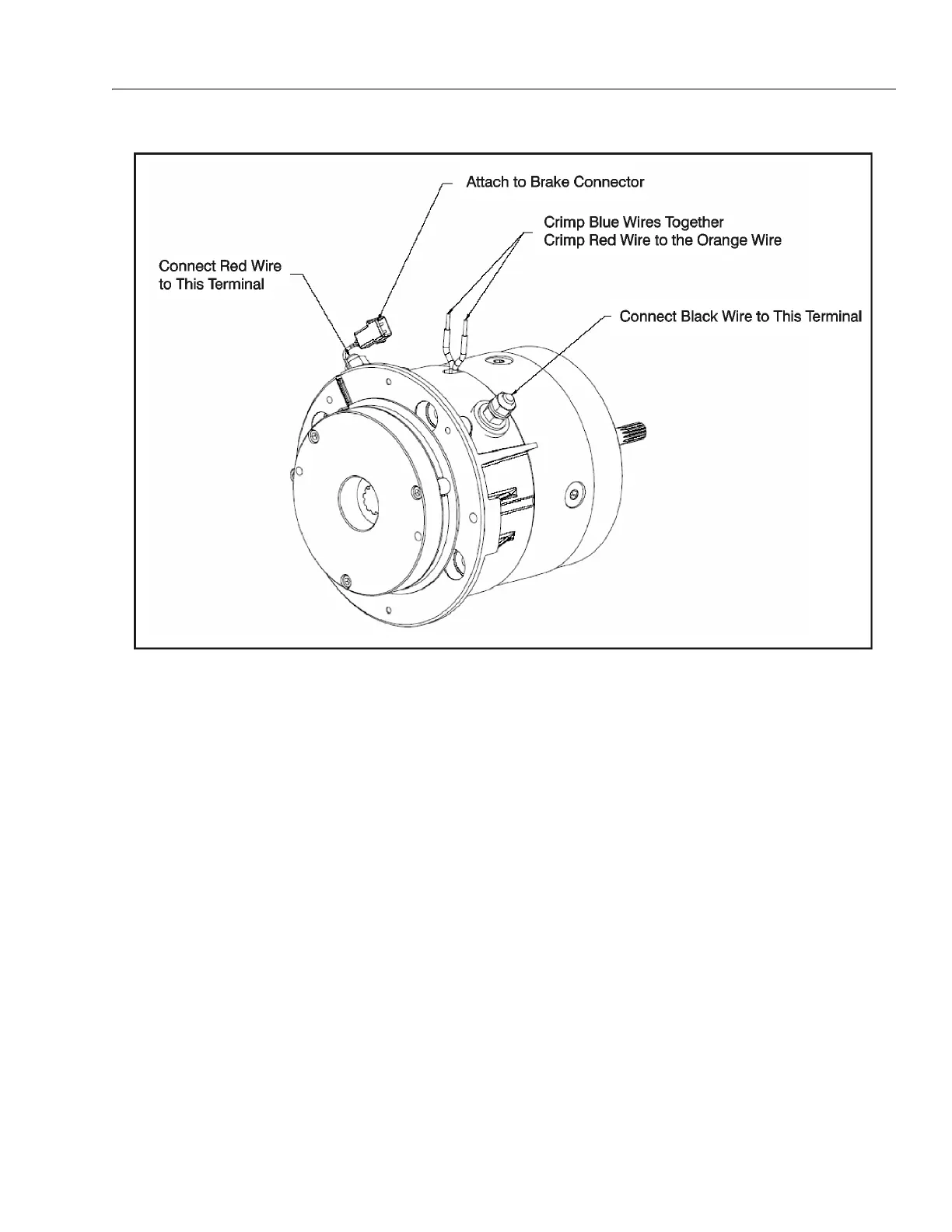

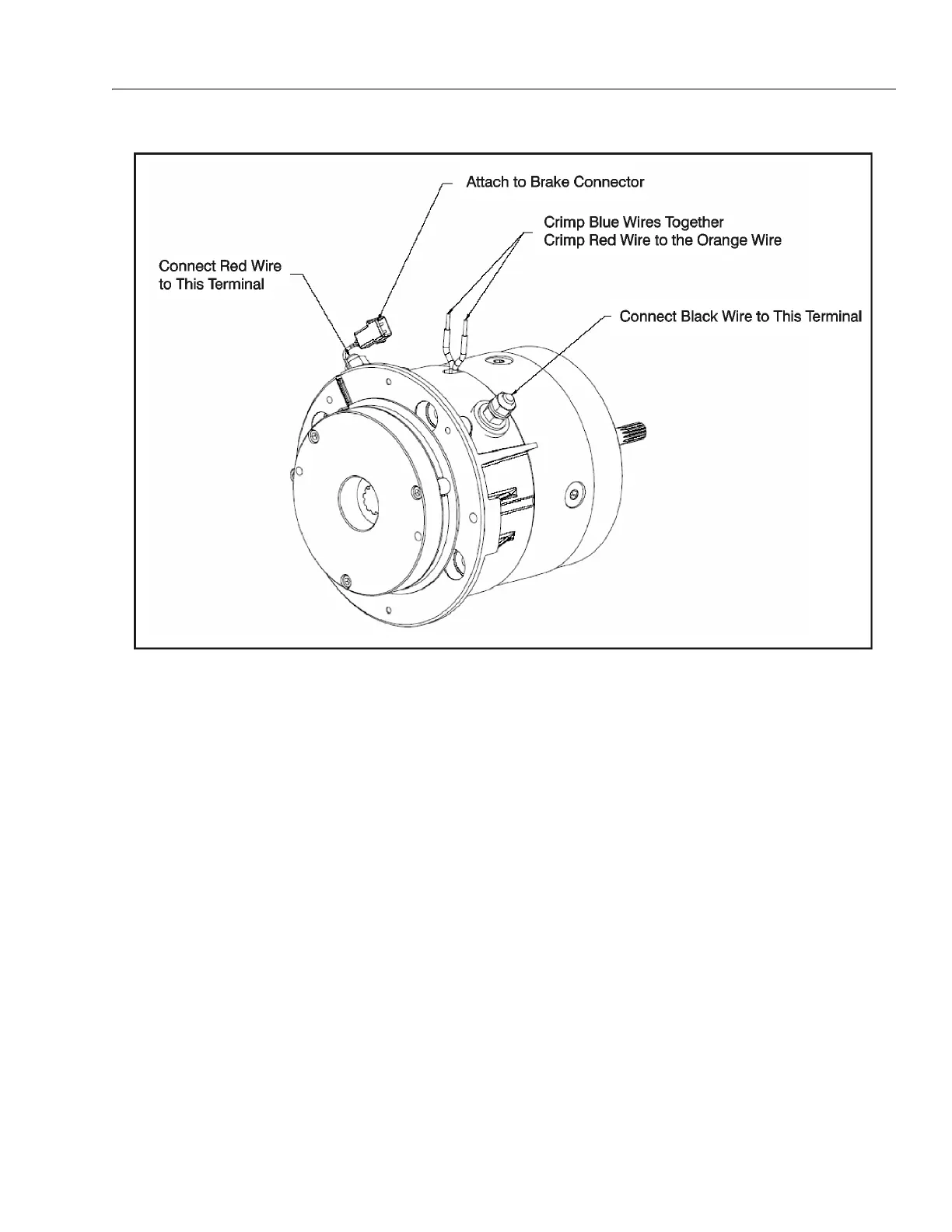

Figure 3-31. Wire Harness Connections

Loading...

Loading...