SECTION 3 - CHASSIS & SCISSOR ARMS

3121166 – JLG Lift – 3-33

NOTE: Reference Figure 3-29., Drive Motor Components for

part names and locations when servicing the Drive

Motor.

Periodic maintenance consisting of inspections of motors,

batteries and wiring circuitry is recommended.

ALWAYS WEAR EYE PROTECTION DURING ANY MAINTENANCE

OPERATION.

Drive Motor Troubleshooting

1. Turn off power to unit and disconnect main battery

power. Disconnect drive motor connections from the

Power Module.

2. Verify field continuity between the blue and orange

wires. If available, use a 4-wire ohmmeter to verify

the field resistance per the applicable motor specifi-

cation below.

3. Verify armature continuity between the red and black

wires. If available, use a 4-wire ohmmeter to verify

the field resistance per the applicable motor specifi-

cation below.

4. Using a dielectric tester, verify that there are no

shorts between the following items:

a. Field connector pins and the case of the motor.

b. Armature terminals and the case of the motor.

c. Field connector pins to the armature terminals.

5. Verify continuity in 2 pin brake connector (yellow

and brown wires). Measure the brake resistance and

verify that it is between 18 and 22 Ohms.

Drive Motor Disassembly

NOTE: Refer to Figure 3-29.

1. Remove the two Cover Plate Mounting Screws (14)

holding the Cover Plate (13) in place and remove the

cover plate from the motor.

2. Remove the Brake Cover Mounting Screws (15)

holding the Brake (11) in place and set aside. These

screws are used to manually release the brakes.

3. Remove the two Terminal Cover Mounting Screws

(16). Slide the strain relief of the Wire Harness (1)

out of the cover and remove the cover from the

motor.

4. Discard the Gasket (12) that was located under the

brake and terminal covers.

5. Remove the wire harness from the motor by discon-

necting the brake connection and armature connec-

tions. Cut the field connection close to the crimp

connection on the motor side.

6. Install the two Brake Cover Mounting Screws (15)

into the threaded holes in the brake assembly and

tighten to manually release the brake (see Figure 3-

10.).

7. Remove the three screws holding the brake assem-

bly to the motor. Carefully remove the brake assem-

bly, brake disc and reaction disc from the motor by

sliding off of the shaft.

8. Remove the screws holding the Commutator End

Head (9) in place and remove the commutator end

head from the frame and field assembly. The Arma-

ture (2) will be attached to the commutator end

head.

9. Pull back the Brush Springs (4) in the commutator

end head, pull the brush back and rest the springs

on the side of the brush. The brushes should move

freely within the holders.

10. Use an arbor press or a bearing puller to remove the

armature from the commutator end head assembly.

11. Remove the Snap Ring (7) and Bearing (8) from the

commutator end head. Discard the bearing.

Drive Motor Inspection and Service

NOTE: Refer to Figure 3-29.

1. Carefully blow out any accumulated carbon dust

and dirt from the Commutator End Head (9) and the

Frame & Field Assembly (2) using clean, oil free,

compressed air.

2. Replace Brushes (5) that are worn below their

usable length of 0.6 in (1.5 cm), show signs of

uneven wear or signs of overheating, such as discol-

ored brush shunts and brush springs. Brushes

should always be replaced in complete sets of four.

Use identical replacement parts; do not substitute

brush grades as the brushes are matched to the

motor type and application to provide the best ser-

vice. Substituting brushes of the wrong grade can

cause premature commutator failure and excessive

brush wear.

3. Make sure the Brush Box Assembly (6) is tight on

the commutator end head. Replace brush box

assemblies in the commutator end head if they are

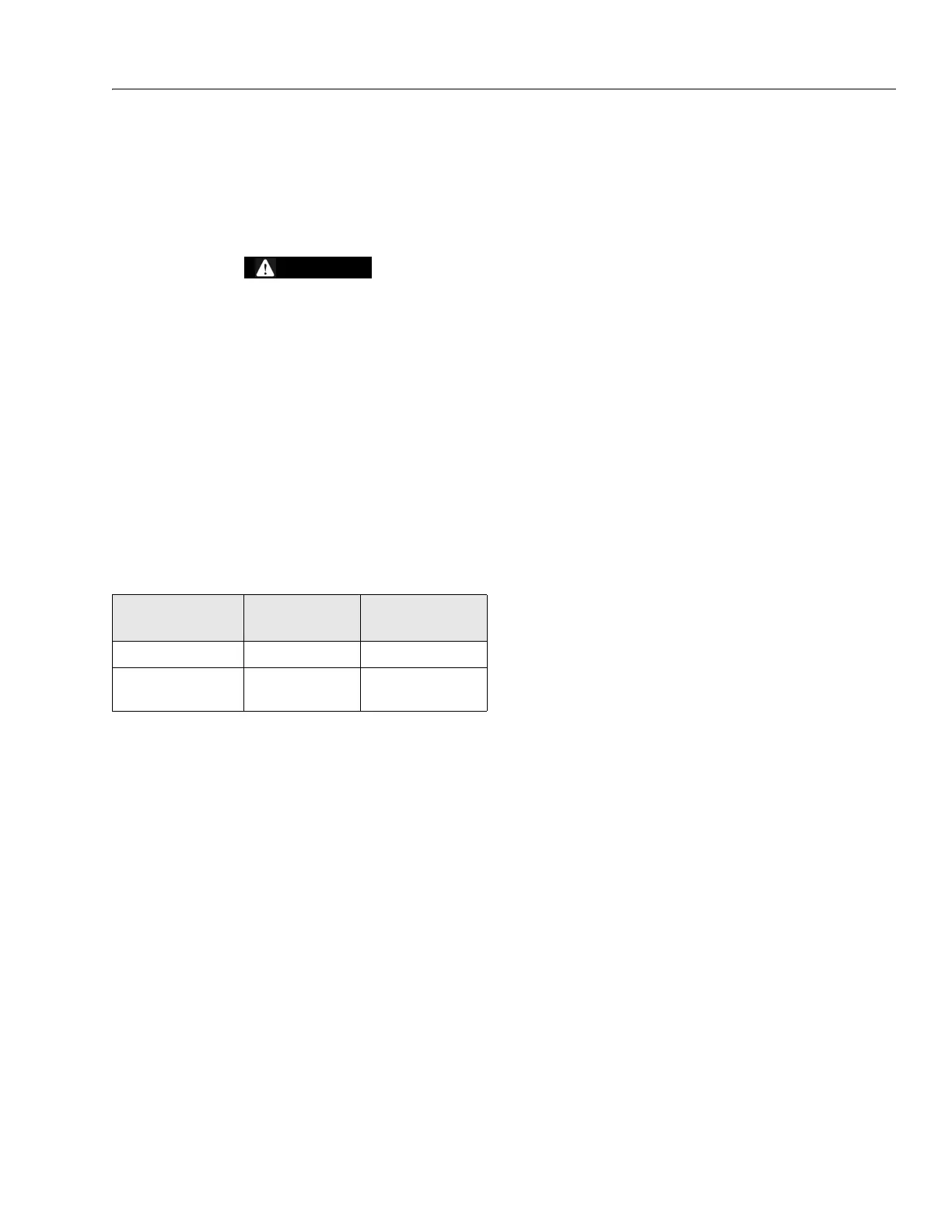

Model

Field Resistance

@ 75°F (24°C)

Armature Resistance

@ 75°F (24°C)

1930ES 0.21 Ohms 0.037 Ohms

2030ES/2630ES/

2646ES/3246ES

0.127 Ohms 0.051 Ohms

Loading...

Loading...