SECTION 5 - JLG CONTROL SYSTEM

5-14 – JLG Lift– 3121166

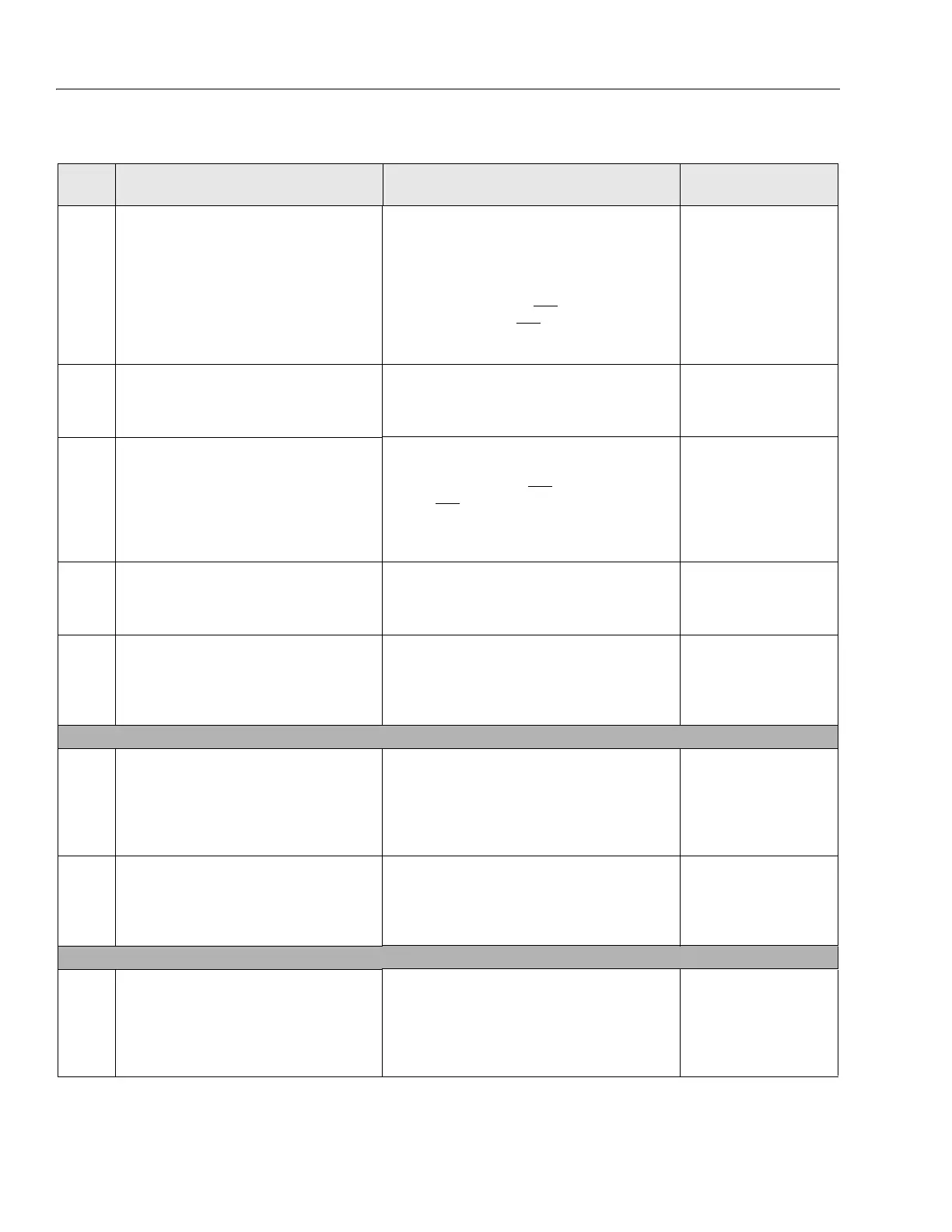

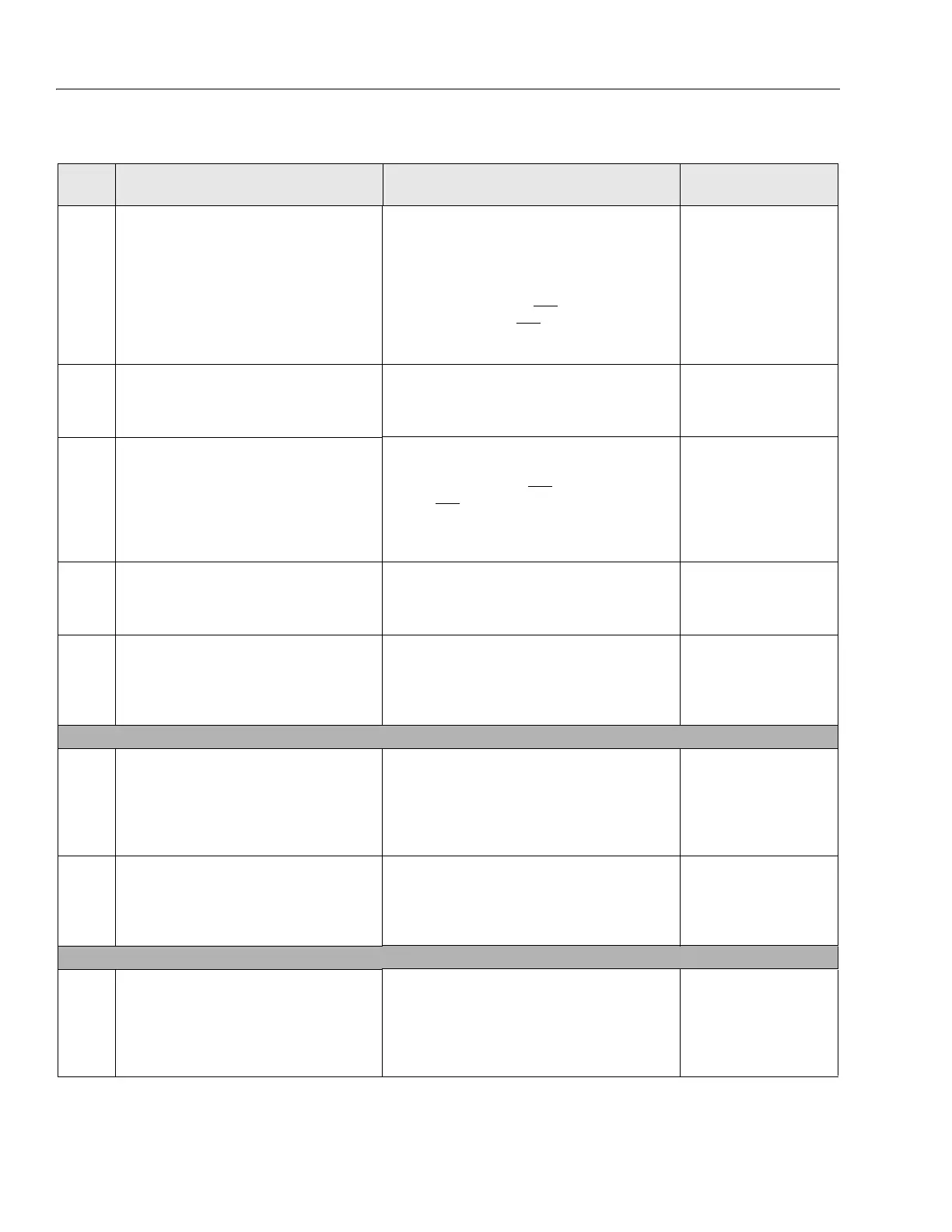

2 5 E LEV PROX PERM ANENTLY CLOSED – CHECK

PROX AND ANGLE ADJUSTMENT

The Elevation Proximity Switch is closed to indicate that the

platform is stowed, but the elevation sensor’s voltage indi-

cates that the platform is elevated. To be conservative, the

control system will assume that the platform is elevated,

and the drive speed will be restricted to elevated.

Elevation Sensor is “Healthy” AND

the Elevation Sensor’s

Zeroed Voltage is > 0.15V AND the Elevation Prox Switch

is Closed for 2000mS. Retained until situation changes.

Refer to Platform Position Sensor Functionality.

Check elevation switches.

Replace if necessary.

2 5 DRIVE & LIFT PREVENTED – BRAKES ELECTRI-

CALLY RELEASED FOR TOWING

The manual brake release has been activated to allow the

vehicle to be towed.

Brake release digital input is energized

Drive and Lift Prevented

Disengage the manual brake

release.

2 5 DRIVE PREVENTED – ELEVATED ABOVE DRIVE

CUTOUT HEIGHT

The Drive Cutout functionality is enabled, and the platform

is elevated above the calibrated cutout height.

Drive Cutout is set to 1=YES AND

the Elevation Sensor is

“Healthy” AND the Elevation Sensor’s Zeroed Voltage is

Greater Than the Calibrated Drive Cutout Voltage.

Refer to Drive Cutout Functionality.

Check elevation switches

Check pothole switches.

2 5 M ODEL CHANGED -- HYDRAULICS SUSPEN DED

- CYCLE EMS

The model selection has been changed. Check ANALYZER ->

MACHINE SETUP -> MODEL

NUMBER.

Replace ground board.

2 5 DRIVE PREVENTED -- BRAKES NOT RELEASING While driving on a level surface, armature current was >

150A for five seconds. Brakes assumed to not be releasing

properly.

Ensure vehicle is not stuck on

something preventing move-

ment. Check/repair drive

motor wiring, brakes or

mechanical issues.

Help messages with the 3-1 flash code indicate that a contactor did not close when energized.

3 1 OPEN CIRCUIT LINE CONTACTOR The Power Module’s line contactor drive circuitry passed

power-up self-tests, but the line contactor did not close

when energized.

The Power Module is reporting a “Contactor Did Not Close”

Fault Code (15d).

Drive, Steer, & Lift Up Prevented.

Refer to CANbus documenta-

tion for Power Module Mes-

sage - Status.

3 1 CONTACTOR DR IVER PERMANE NTLY OFF T he Power Modul e’s Line Conta ctor drive circuitry fa iled to

energize during power-up self-tests.

The Power Module is reporting a “Contactor Driver 1 Per-

manently Off” Fault Code (22d).

Drive, Steer, & Lift Up Prevented.

Refer to CANbus documenta-

tion for Power Module Mes-

sage - Status.

Help messages with the 3-2 flash code indicate that a contactor did not open when de-energized.

3 2 LINE CONTACTOR MISWIRED ON OR WELDED The Power Module’s Line Contactor Drive Circuitry passed

power-up self-tests, but the line contactor did not open

when de-energized.

The Power Module is reporting a “Contactor Welded” Fault

Code (14d).

Drive, Steer, & Lift Up Prevented.

Refer to CANbus documenta-

tion for Power Module Mes-

sage - Status.

Table 5-2. Flash Code Listing

FLASH

CODE

HELP MESSAGE CAUSE POSSIBLE RESOLVE

Loading...

Loading...