LPKF Laser & Electronics AG | V. 1.0

7.2 Personal protective equipment

The following protective equipment must be worn when performing startup and

maintenance tasks:

Safety shoes according to EN ISO 20345, protection class S1

Protective gloves according to EN 388, protection class 2

Respirator mask according to EN 149, protection class FFP2

Latex lab gloves, protection class 1

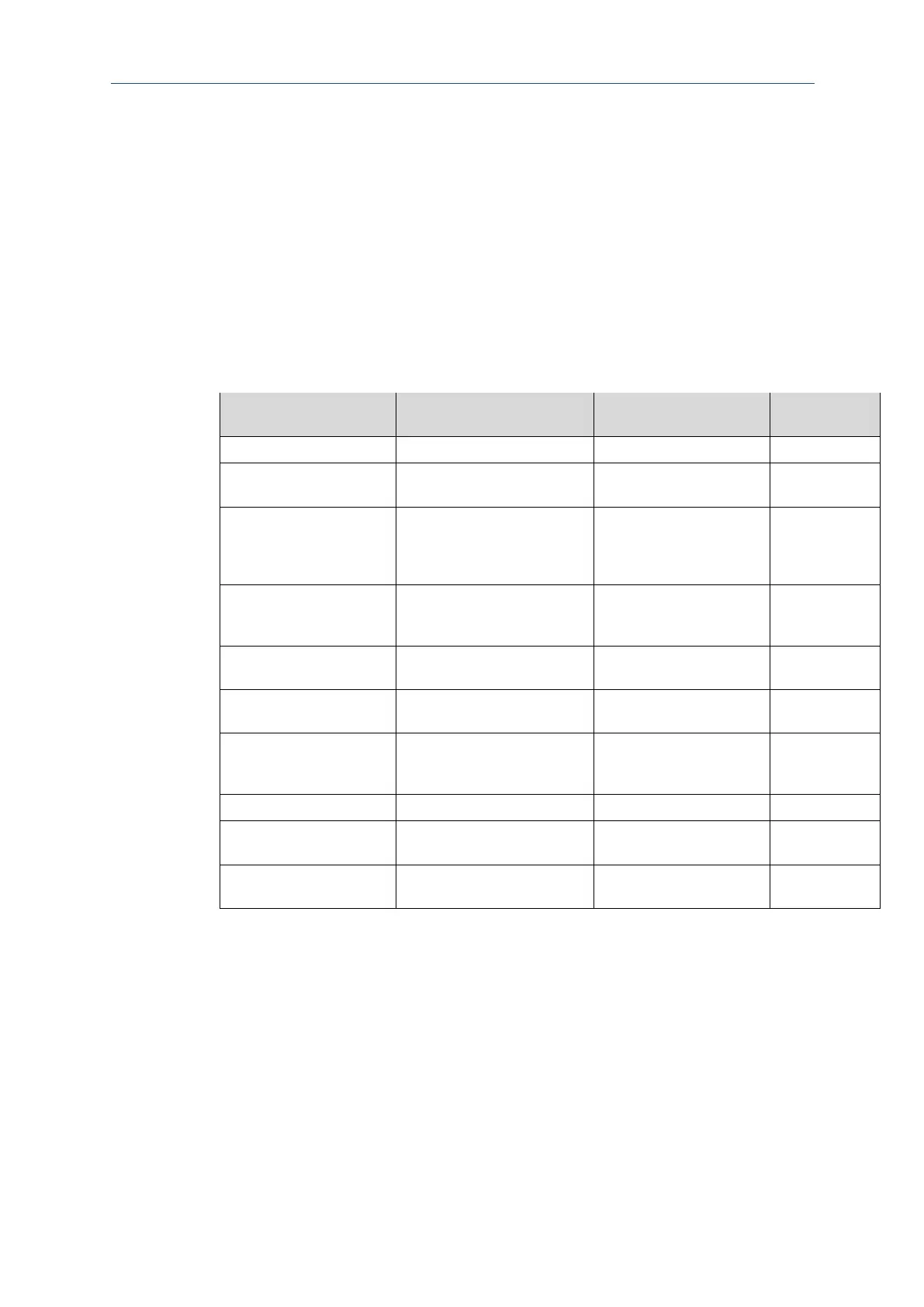

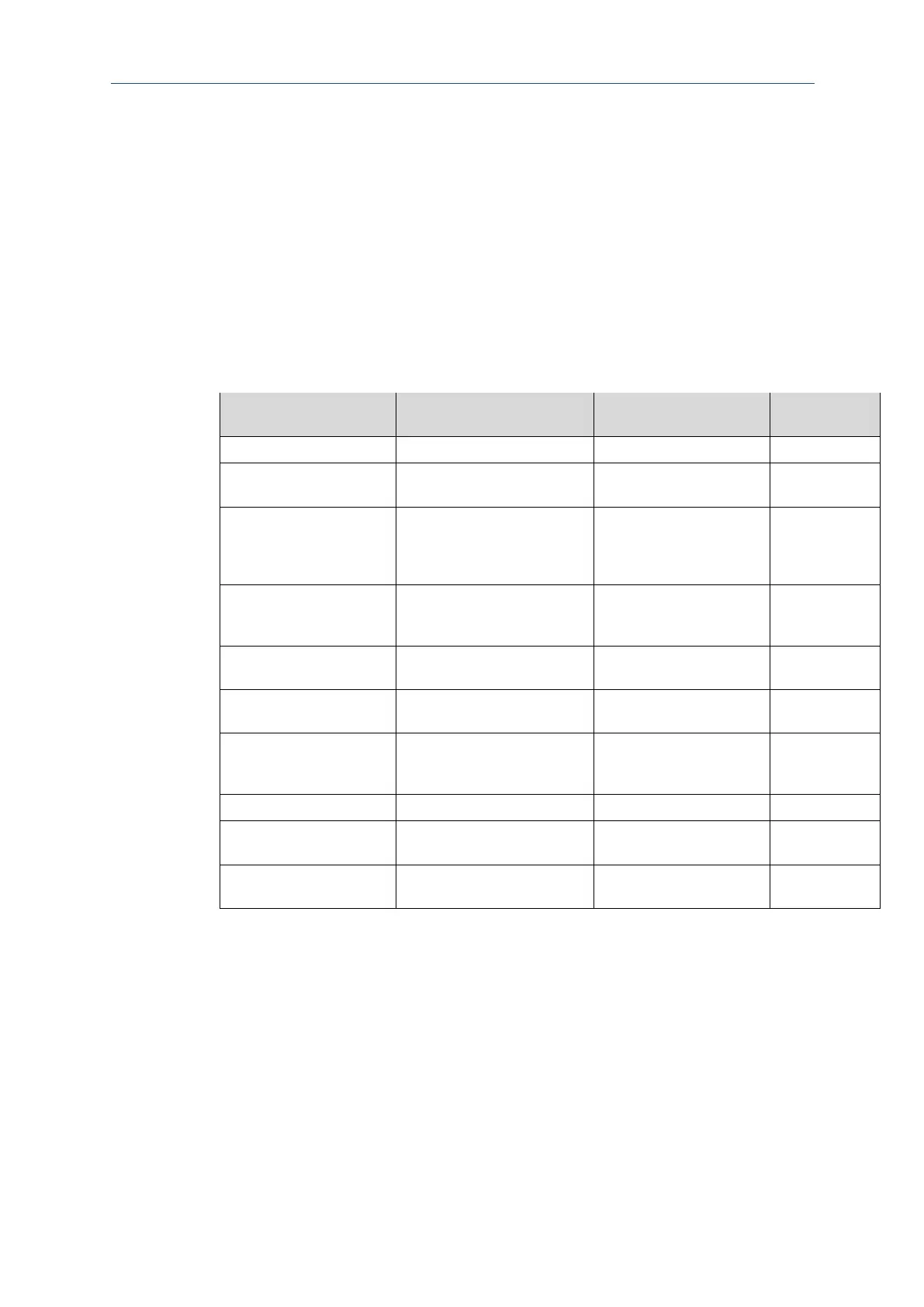

7.3 Maintenance schedule

The following table lists the maintenance tasks that are to be performed by personnel

trained for these tasks.

Circuit board plotter

(interior and cover)

After 40 operating hours or at

least weekly or when

prompted by the system

software

Visual check and

cleaning/replacing, if

necessary.

Drive spindle

Linear guides

After 500 operating hours or

at least every six months

After 500 operating hours or

at least every six months

After 500 operating hours or

at least every three months

Draining condensate and

replacing the filter if

necessary.

When the extraction power

weakens noticeably.

HEPA filter of the

extraction system

After 1000 operating hours

Table 15: Maintenance schedule for the maintenance personnel of the operator

Loading...

Loading...