IMPULSE•VG+ Series 3 Instruction Manual – 07/25/05

5-51

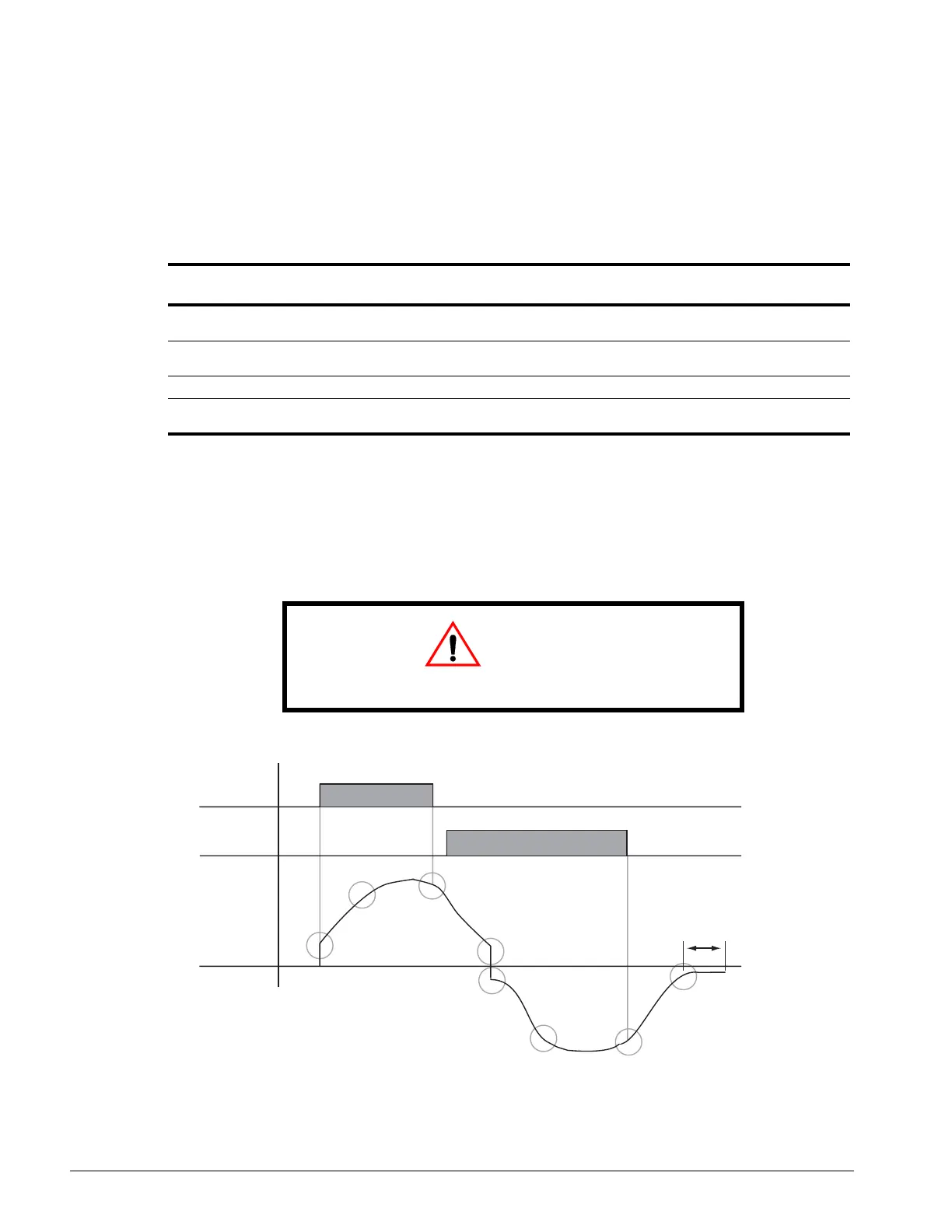

S-Curve Acceleration/Deceleration

A S-Curve pattern is used to reduce shock and provide smooth transitions during machine

acceleration and deceleration. S-Curve characteristic time is the time from the output frequency to

the set accel/decel time. See S-Curve Characteristic timing diagrams below and on the following

page.

The figure below shows FWD/REV run switching during deceleration to stop. The S-curve function

will add time to the acceleration and deceleration. Time to accelerate from the minimum frequency

to the maximum frequency (total acceleration) = B5-01 + (D9-01 + D9-02)/2.

Figure 5-30: S-Curve Characteristics–FWD/REV Operation

Parameter

Code Display Function Range Initial Value

Access

Level

D9-01* S-Crv Acc @ Start Sets S-Curve time at Accel

start

0.00–2.50 sec − Adv

D9-02* S-Crv Acc @ End Sets S-Curve time at Accel

end

0.00-2.50 sec − Adv

D9-03* S-Crv Dec @ Start Sets S-Curve time Decel start 0.00–2.50 sec − Adv

D9-04 S-Crv Dec @ End Sets S-Curve time at Decel

end

0.00–2.50 sec 0.20 Adv

*Initial value is determined by X-Press Programming (Table 4.1 to 4.2).

CAUTION

CAUTION Accel/Decel times will be extended.

requency

utput

un(FWD)

ommand

un(REV)

ommand

D9-01

D9-02

D9-03

D9-04

D9-01

D9-02

D9-03

D9-04

DC Injection Brakin

Time at Stop

D1-04

Loading...

Loading...