M&M

R

EFRIGERATION

I

NC

. A-3

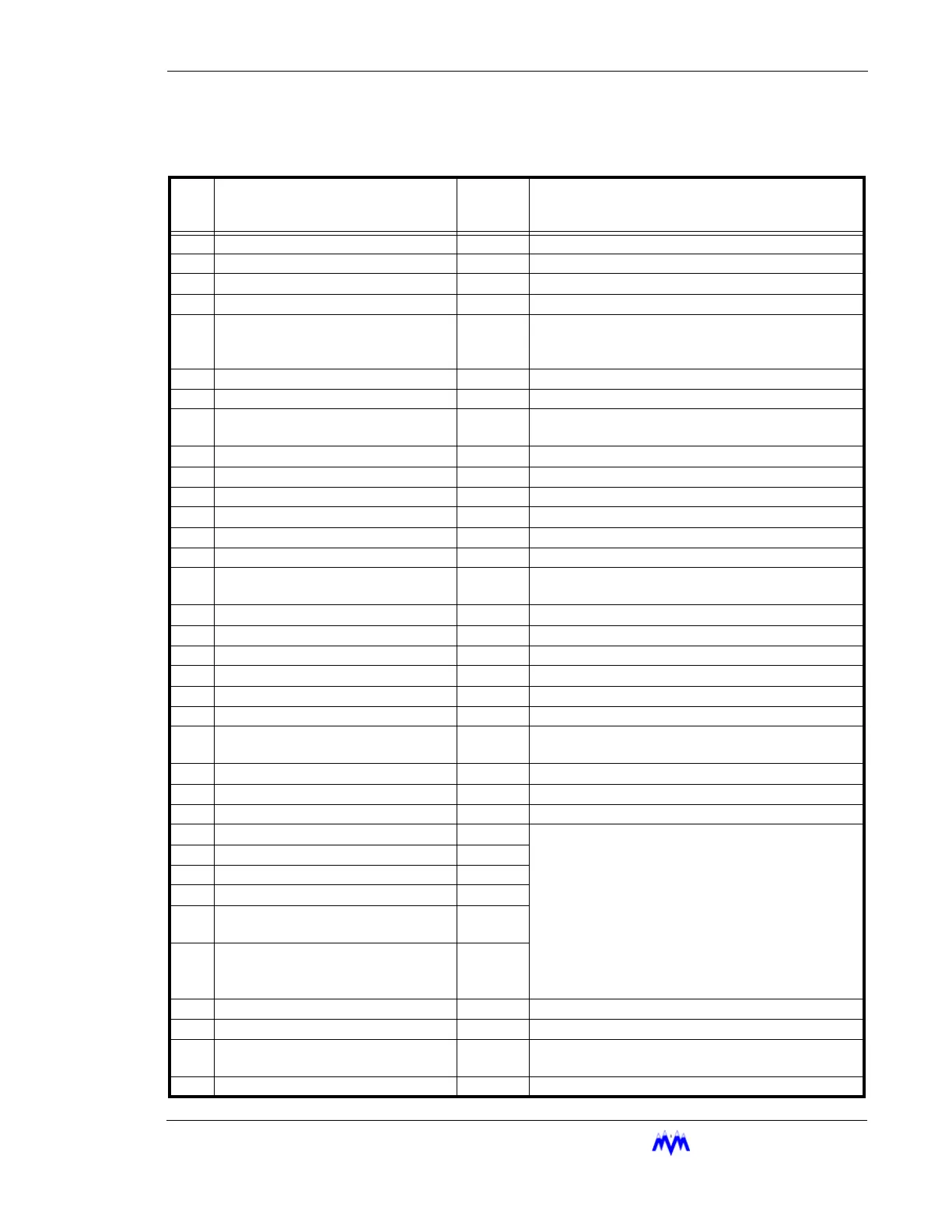

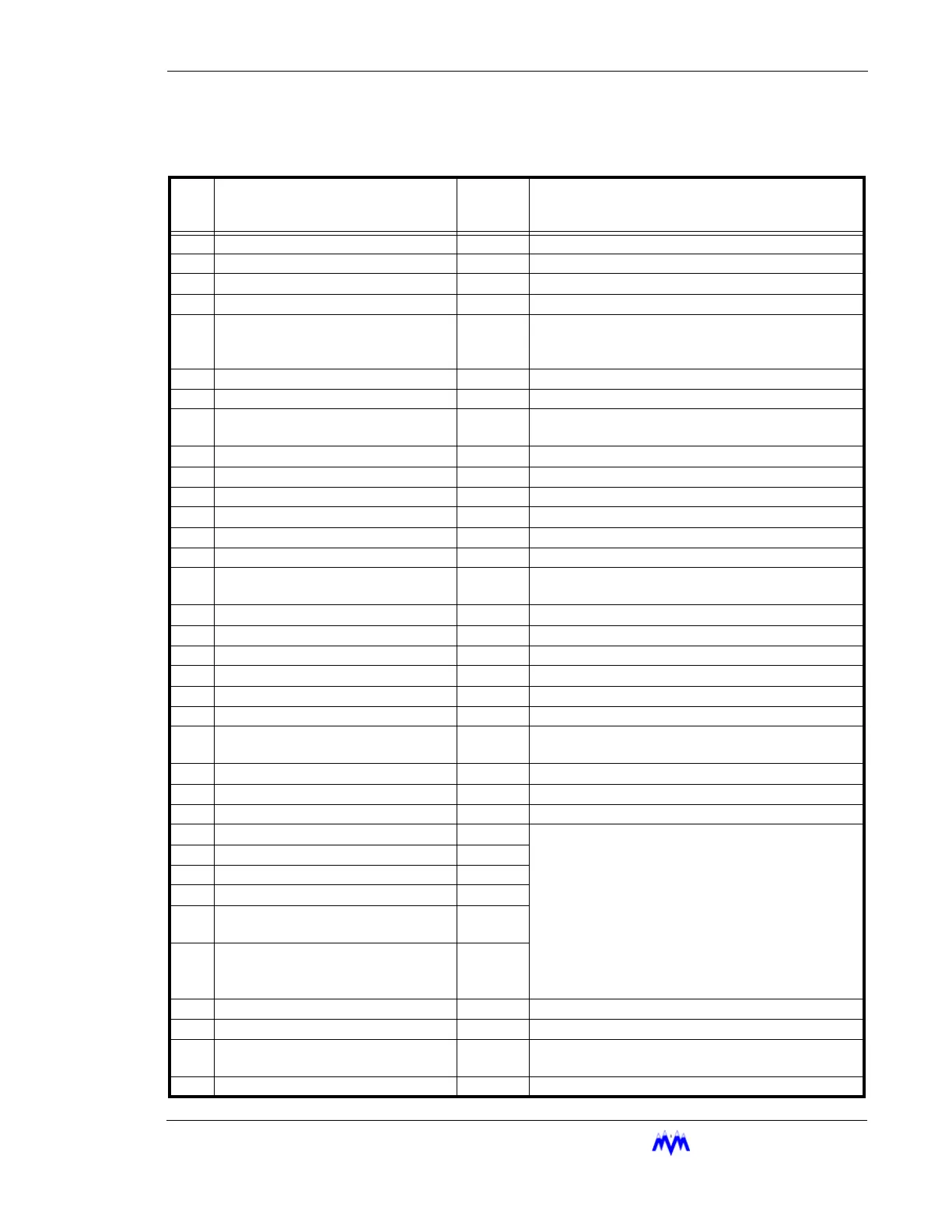

Appendix A: Discrete Alarms

Discrete Alarms

No. Parameter Name Level Comments

1.

Memory Initialized Alarm

2.

Frame Overrun Alarm

3.

Timer Allocation Fail

4.

RAM Size Failure Low Fail Indicates a hardware problem with the RAM Chip.

5.

Power Low Reset Fail The Power has drooped below a threshold but did

not completely go away. A sensor or other device

may be shorted

6.

Power Fail Reset Fail Power was lost

7.

Pushbutton Reset Fail The reset button on Main Board was pressed.

8.

Watchdog Reset Fail The Software was unable to complete it’s cycle.

May be communications or interrupt related.

9.

Operator Reset Fail Reset from a screen save from the keypad or PC

10.

Auxiliary Contact 1 Fail Open to Fail

11.

Auxiliary Contact 2 Fail Open to Fail (Not available with Economizer Option)

12.

Suction Pressure Sensor Bad SNSR

13.

Discharge Pressure Sensor Bad SNSR

14.

Oil Press After Filter Sensor Bad SNSR

15.

Oil Press Before Filter Sensor Bad SNSR Oil pressure below filter sensor bad (all others)

Oil pressure above discharge sensor bad (STAL)

16.

Discharge Temperature Sensor Bad SNSR

17.

Oil Temperature Sensor Bad SNSR

18.

Oil Sump Temperature Sensor Bad SNSR

19.

Suction Temperature Sensor Bad SNSR

20.

Motor Current Sensor Bad SNSR

21.

Slide Valve Sensor Bad SNSR

22.

Process Temperature Sensor Bad

(Option)

SNSR

23.

Starting Oil Pressure Low OEM

24.

Starting Slide Valve Position High OEM

25.

Stopping Slide Valve Position High OEM

26.

Motor Off/Current Normal/Aux Open Fail The Micro checks state of Motor Output, Aux Input,

and Motor Current to verify correct operation. Motor

Current above 10% of entered CT size or Aux con-

tact closed indicates the motor is running.

If Motor is running when it should be off, the Micro

will take the following steps: (1) Failure signal is

generated to alert operator; (2) Oil pump is started, if

one exists; (3) Slide valve is forced to continuous

unload, and; (4) Liquid injection controls on oil tem-

perature

27.

Motor On/Current Low/Aux Open Fail

28.

Motor On/Current Normal/Aux Open Fail

29.

Motor Off/Current Low/Aux Closed Fail

30.

Motor Off/Current Normal/Aux

Closed

Fail

31.

Motor On/Current Low/Aux Closed Fail

32.

Economizer Shutdown (Option) Fail Replaces Aux 2 Shutdown

33.

Master Shutdown Fail The master has requested a shutdown

34.

ECP Shutdown Fail A shutdown was requested using the ECP or Mod-

bus protocol

35.

DF1 Shutdown Fail A shutdown was requested using the DF1 Protocol

Loading...

Loading...