Standard Screw Compressor - RWB Series

3-18

M&M

R

EFRIGERATION

I

NC

.

Power Fail Restart

The operator can define a power fail restart time from the miscellaneous time setpoint screen.

If the CCS is reset manually or due to a loss of power the down time is calculated and com-

pared to this setpoint. If power was off longer than the power fail restart time a failure is

reported. If the power loss was less then the setpoint no failure is reported and the compres-

sor remains on-line and is allowed to automatically restart if required.

Remote Status Information

The Remote option provides for a group of discrete outputs for Remote status informa-

tion. The list of Remote status outputs is as follows.

The minimal and intermediate load positions can be defined using the Remote Slide Valve

Setup screen from the Configuration menu. This allows the operator to adjust the remote

slide valve outputs to the needs of the facility.

Process Temperature Control (Option)

When the Process Temperature option is enabled, the screw compressor slide valve position

is adjusted to maintain the outlet temperature of a product or process instead of suction pres-

sure (e.g. chiller outlet temperature control). The control strategy is documented in the

Capacity Control section above.

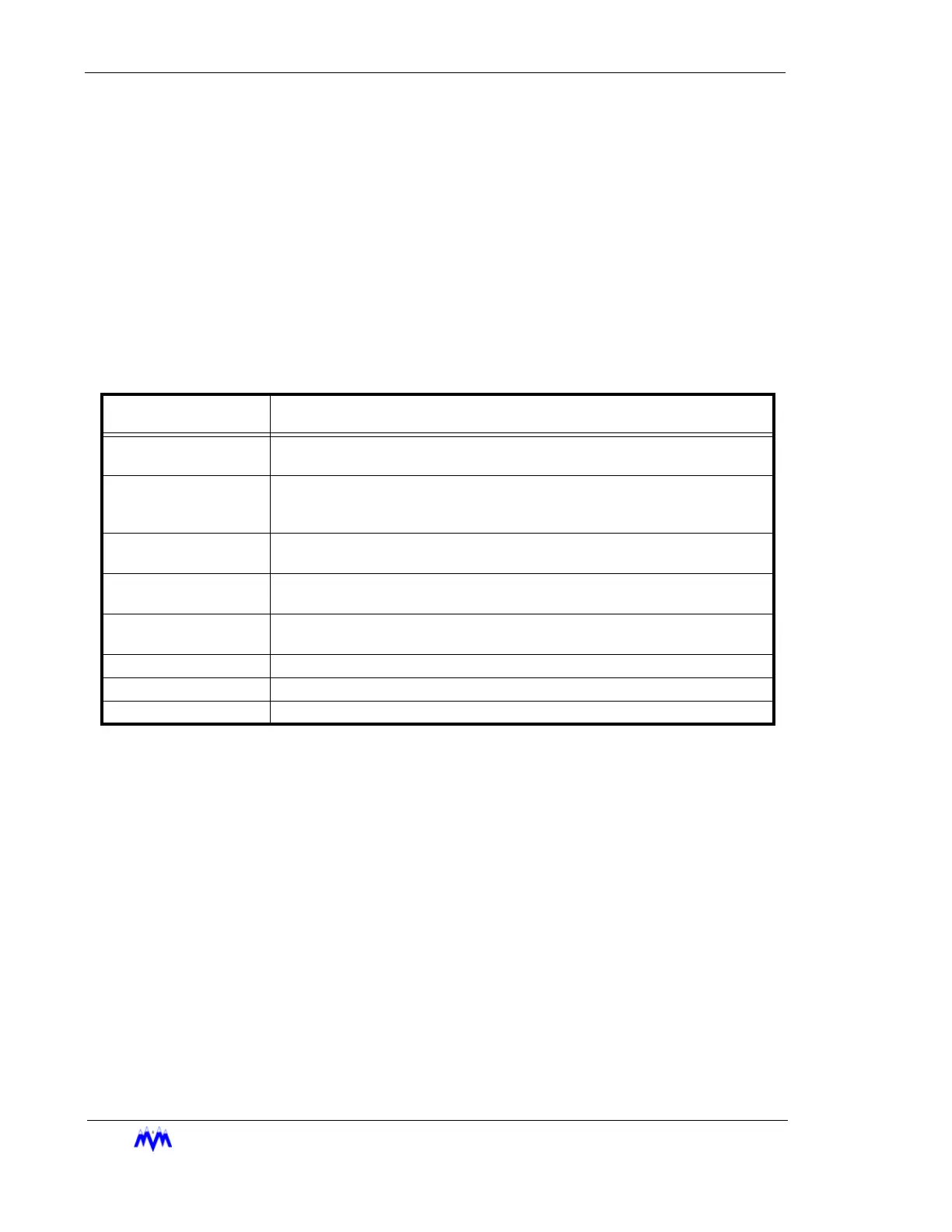

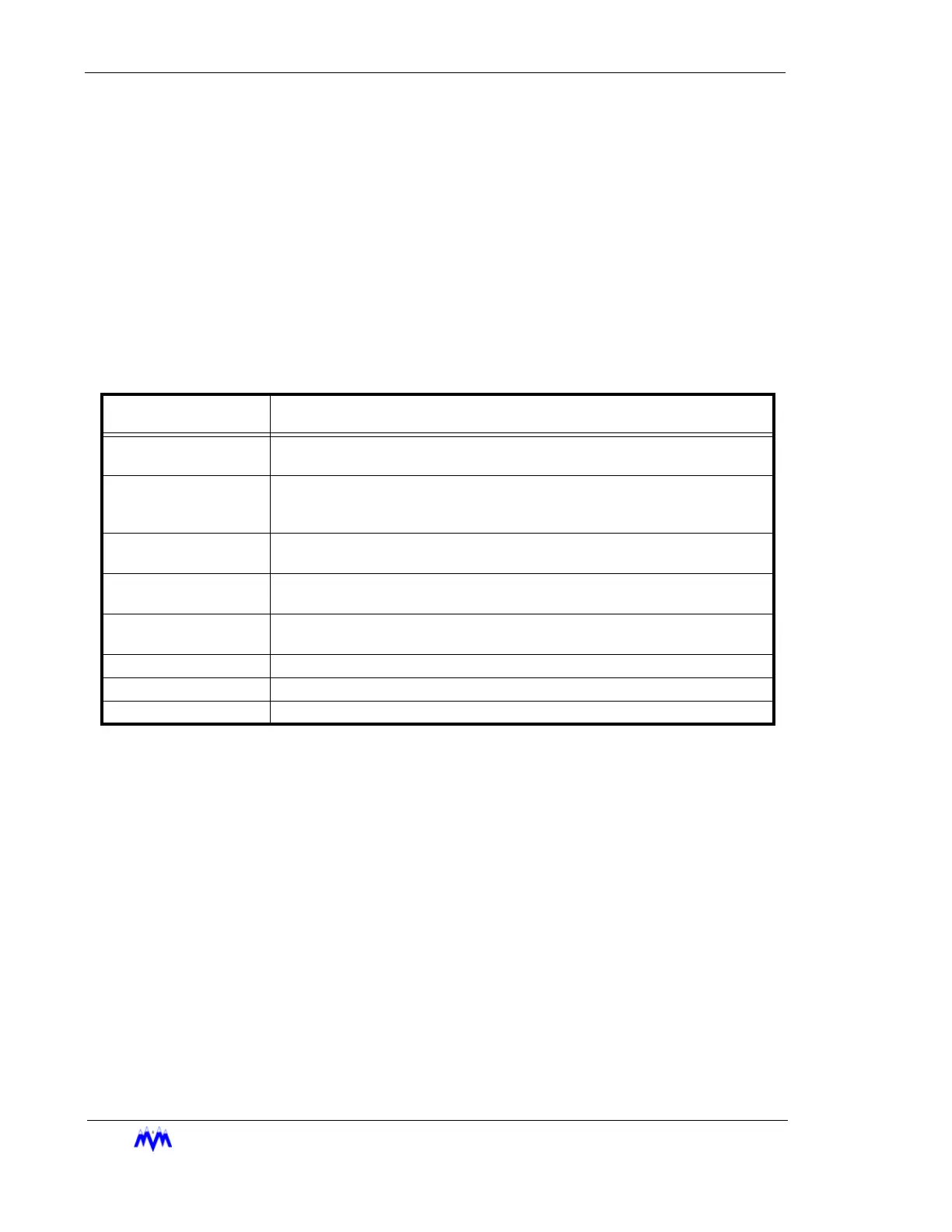

REMOTE STATUS

OUTPUT

DESCRIPTION

LIMITED

ANTI-CYCLE

A high signal indicates the screw compressor cannot be started due to the anti-

cycle timer.

LOAD

LIMITED

A high signal indicates the screw compressor is currently limited or being

forced to unload due to high motor current, high discharge pressure, or capac-

ity ramp.

MINIMAL

LOAD

A high signal indicates the slide valve is above the minimal load position.

INTERMEDIATE

LOAD

A high signal indicates the slide valve is above the intermediate load position.

FULL

LOAD

A high signal indicates the slide valve is fully loaded.

ALARM A high signal indicates an alarm is active.

FAIL A high signal indicates a failure is active.

ON-LINE A high signal indicates the screw compressor is on-line for remote operations.

Loading...

Loading...