M&M

R

EFRIGERATION

I

NC

. 3-23

Chapter 3: Operational Procedures

Manual control of the slide valve is discussed in the Capacity Control section and

alarms and failures are discussed in the Alarm/Failure section of this manual.

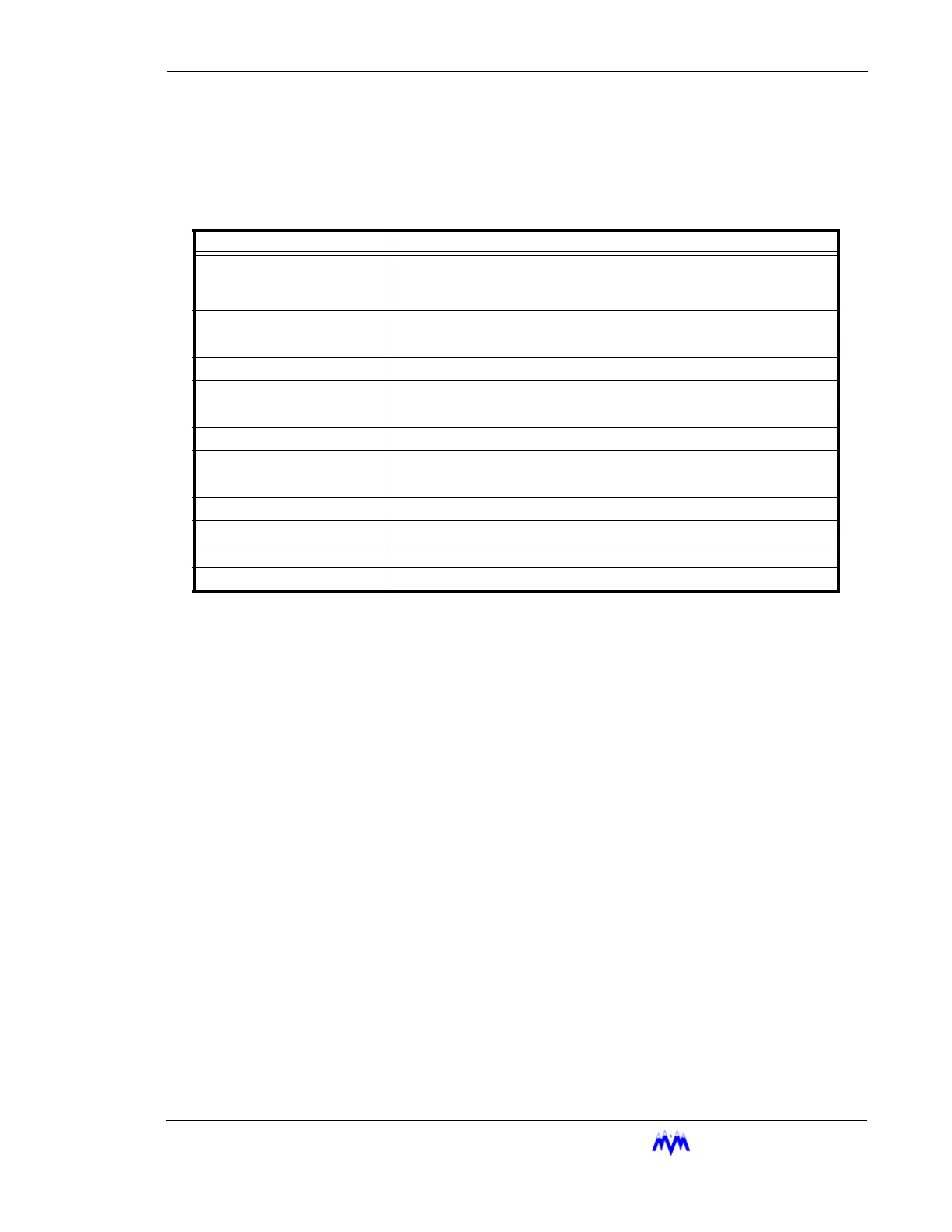

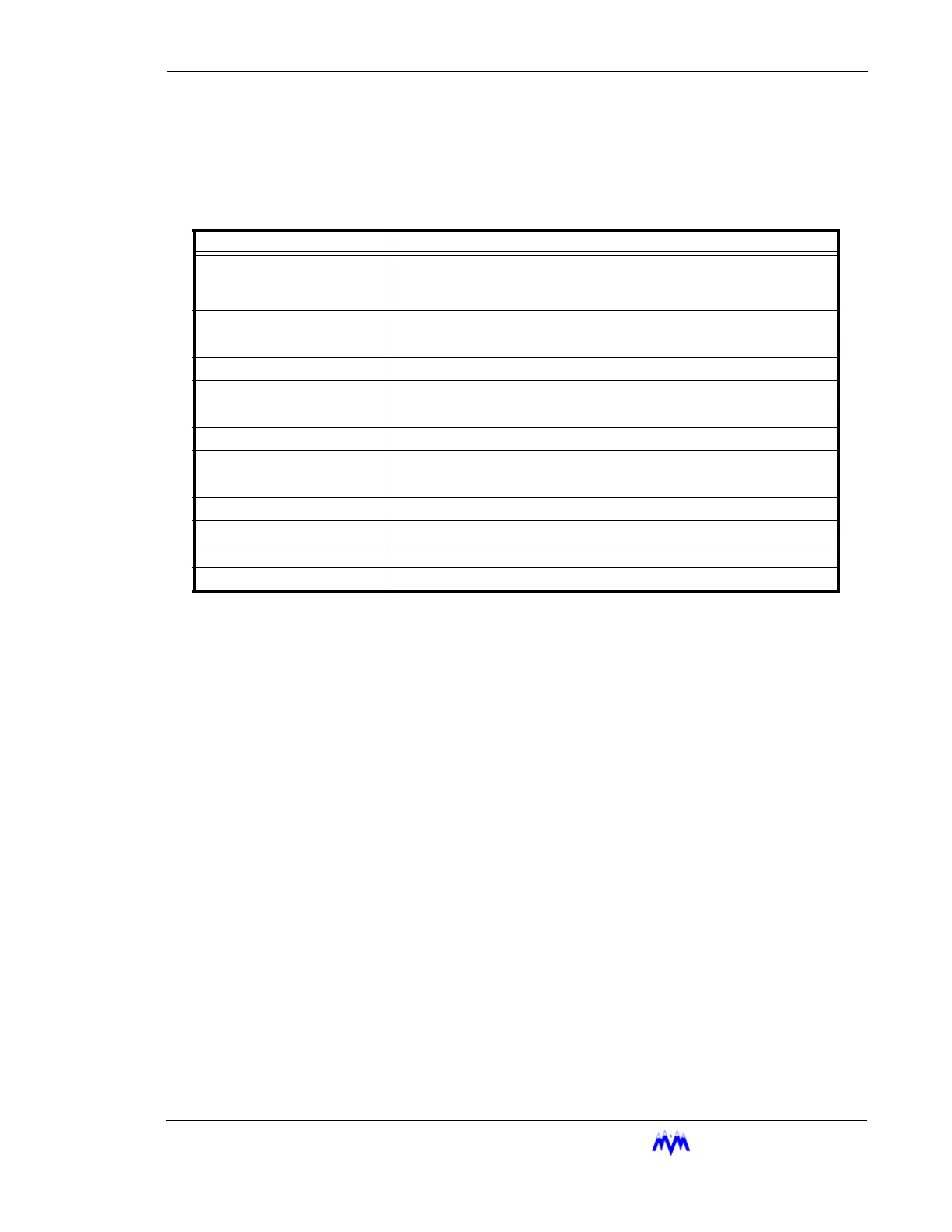

The following table lists the various parameters displayed on the screw status screen.

NOTE: The Oil Pressure and Oil Filter Pressure values are computed values based on various raw

sensor values, depending on the compressor.

Status Banner

The Status Banner is located at the bottom of the Compressor Status screen,

Compressor Graphics screen, Active Alarms & Failures screen, and Auto-Start

Warning status screen. The Banner consists of three highlighted sections which

provide the user with the status of the following system conditions.

• Current System State

• Current Operating mode

• Alarm & Failure Status

PARAMETER DESCRIPTION

S1-S4, P1-P4, SY

The active capacity control setpoint. S1-S1 indicate represent Suc-

tion Pressure setpoints, P1-P4 represent Process Temperature set-

points, and SY represents the Sequenced setpoint.

SP Suction Pressure

DP Discharge Pressure

OP Oil Pressure

OF Oil Filter Differential Pressure

SV Slide Valve Position (Adjusted based on Vi Position)

MA Motor Current

ST Suction Temperature

DT Discharge Temperature

OT Oil Temperature

OS Oil Sump Temperature

PT Process Temperature (Option)

Vi Vi Position

Loading...

Loading...