M&M

R

EFRIGERATION

I

NC

. 3-45

Chapter 3: Operational Procedures

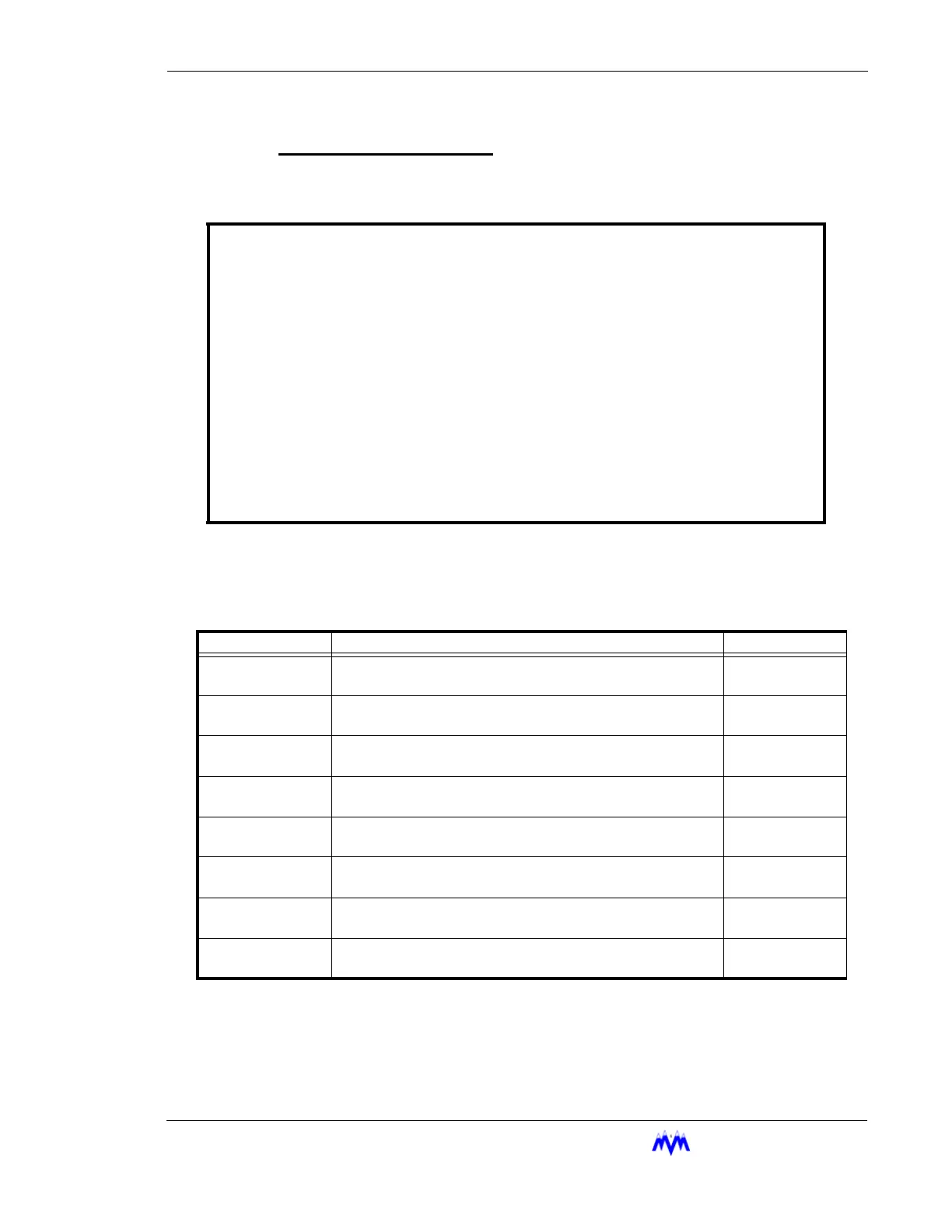

Motor Current Setpoints

The Motor Current Setpoints screen is used to set the motor current control parame-

ters for high alarm, limiting, and ramp conditions.

Motor Current Setpoints Data Entry Screen

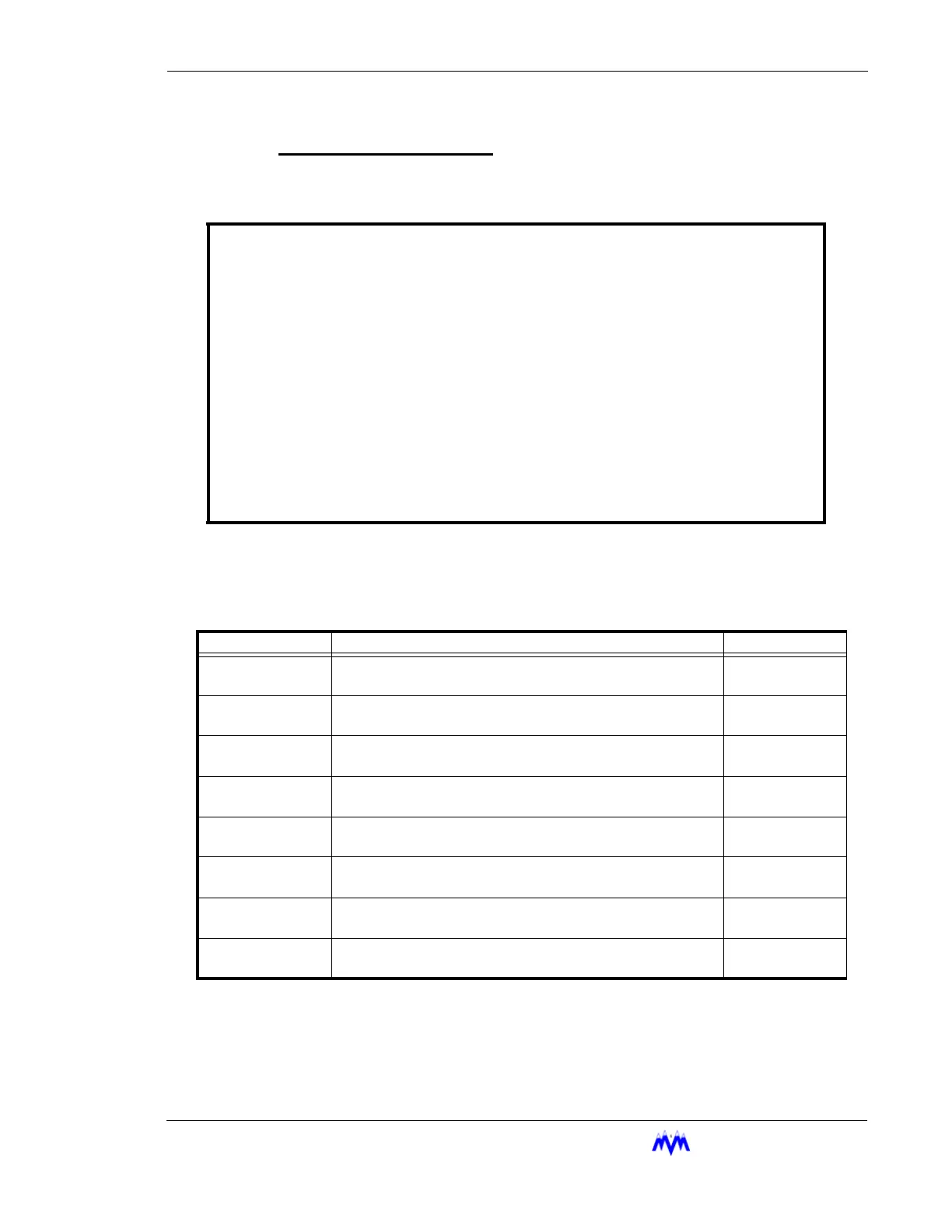

The following table lists the data entry fields for the Motor Current Setpoints

screen

.

Motor Current Data Definitions

MOTOR CURRENT

day mm/dd/yy hh:mm:ss

SETPOINTS

HIGH FAILURE XXX.X PSIG

HIGH ALARM XXX.X PSIG

HIGH UNLOAD XXX.X PSIG

HIGH LIMITING XXX.X PSIG

RAMP UNLOAD XXX.X PSIG

RAMP LIMITING XXX.X PSIG

RAMP START DELAY XXX.X MIN

RAMP START ENABLE DISABLE

TERM DEFINITION RANGE

HIGH

FAILURE

A failure is reported and the compressor is shutdown when

the Motor Current exceeds the High Failure Setpoint.

0 - 2000 AMPS

HIGH

ALARM

An alarm is reported when the Motor Current exceeds the

High Alarm setpoint.

0 - 2000 AMPS

HIGH

UNLOAD

The compressor is forced to unload when this value is

exceeded.

0 - 2000 AMPS

HIGH

LIMITING

The compressor is not allowed to load when this value is

exceeded.

0 - 2000 AMPS

RAMP

UNLOAD

The starting value of the forced unload parameter used dur-

ing ramp start.

0 - 2000 AMPS

RAMP

LIMITING

The starting value of the limiting parameter used during

ramp start.

0 - 2000 AMPS

RAMP START

DELAY

The time delay after the compressor starts where Motor Cur-

rent ramping occurs.

0 - 60 MIN

RAMP START

ENABLE

Allows Motor Current Ramp start to be enabled or disabled.

ENABLE/

DISABLE

Loading...

Loading...