M&M

R

EFRIGERATION

I

NC

. 3-43

Chapter 3: Operational Procedures

Process Temperature Control Group

The Process Temperature Control Group screen is used to setup the Process

Temperature control parameters when the Process Temperature Control option is

enabled.

Process Temperature Control Groups

The following table lists the various parameters displayed on the process temper-

ature setpoints screen.

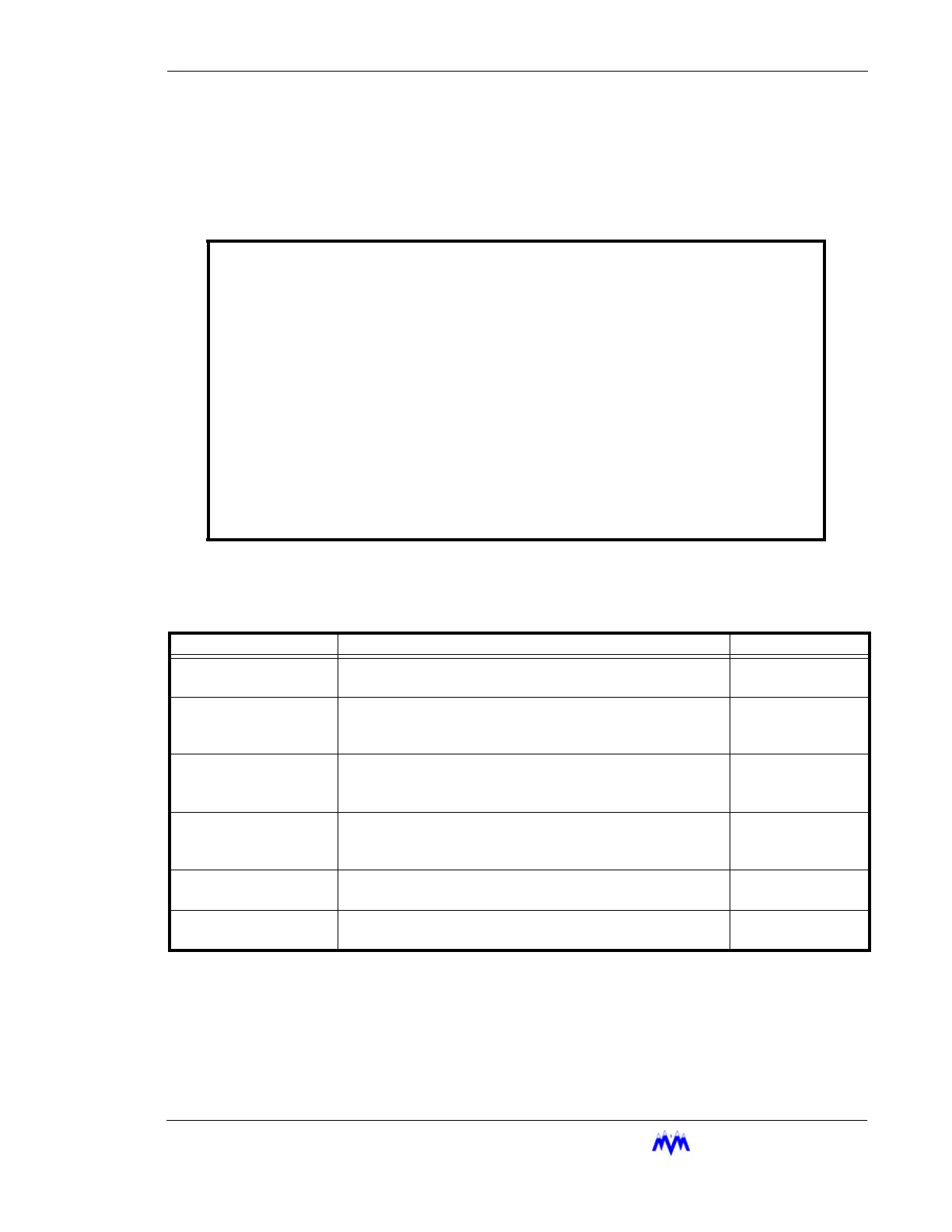

Process Temperature Definitions

PROCESS TEMPERATURE

day mm/dd/yy hh:mm:ss

CONTROL GROUPS

ACTIVE GROUP P1

GROUP P1 GROUP P2 GROUP P3 GROUP P4

-------- -------- -------- --------

CUT-IN XX.X DEGF XX.X DEGF XX.X DEGF XX.X DEGF

CONTROL XX.X DEGF XX.X DEGF XX.X DEGF XX.X DEGF

CUT-OUT XX.X DEGF XX.X DEGF XX.X DEGF XX.X DEGF

LOW ALARM XX.X DEGF XX.X DEGF XX.X DEGF XX.X DEGF

LOW FAILURE XX.X DEGF XX.X DEGF XX.X DEGF XX.X DEGF

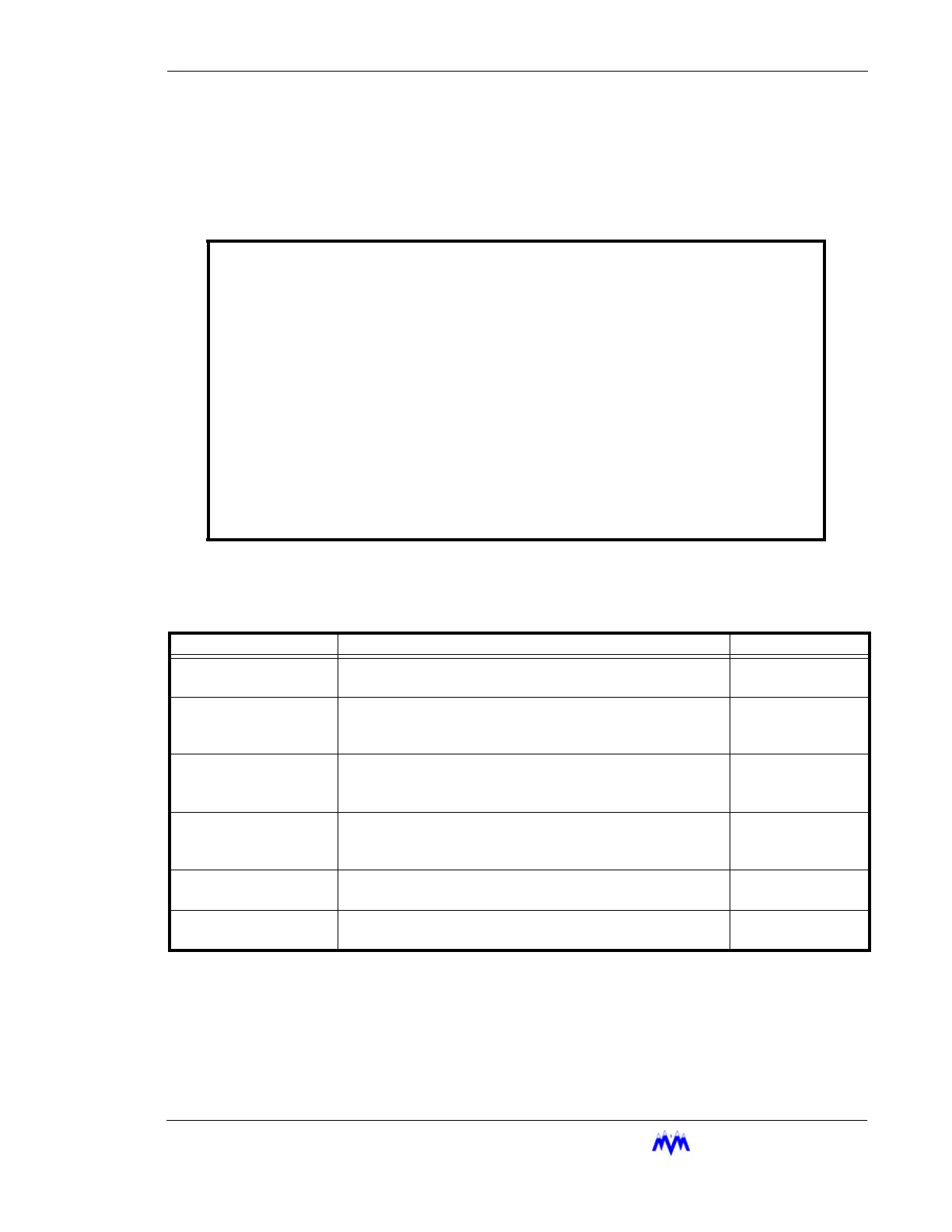

TERM DEFINITION RANGE

ACTIVE

GROUP

There are four possible Process Temperature control groups,

each with its own temperature control parameters.

P1-P4

CUT - IN

In the Automatic mode of operation, the compressor starts

when the Process Temperature becomes greater than the

cut-in temperature.

-58 : 122 DEGF

CONTROL

In the Automatic mode of operation the compressor loads or

unloads as needed to maintain the Process Temperature set-

point.

-58 : 122 DEGF

CUT - OUT

In the Automatic mode of operation, the compressor stops

when the Process Temperature falls below the cut-out tem-

perature.

-58 : 122 DEGF

LOW ALARM

An alarm is reported when the Process Temperature falls

below the low alarm setpoint.

-58 : 122 DEGF

LOW FAILURE

An failure is reported and the compressor is shutdown when

the Process Temperature falls below the low failure setpoint.

-58 : 122 DEGF

Loading...

Loading...