Manitowoc Published 05-03-17, Control # 228-03 1-67

16000 SERVICE/MAINTENANCE MANUAL INTRODUCTION

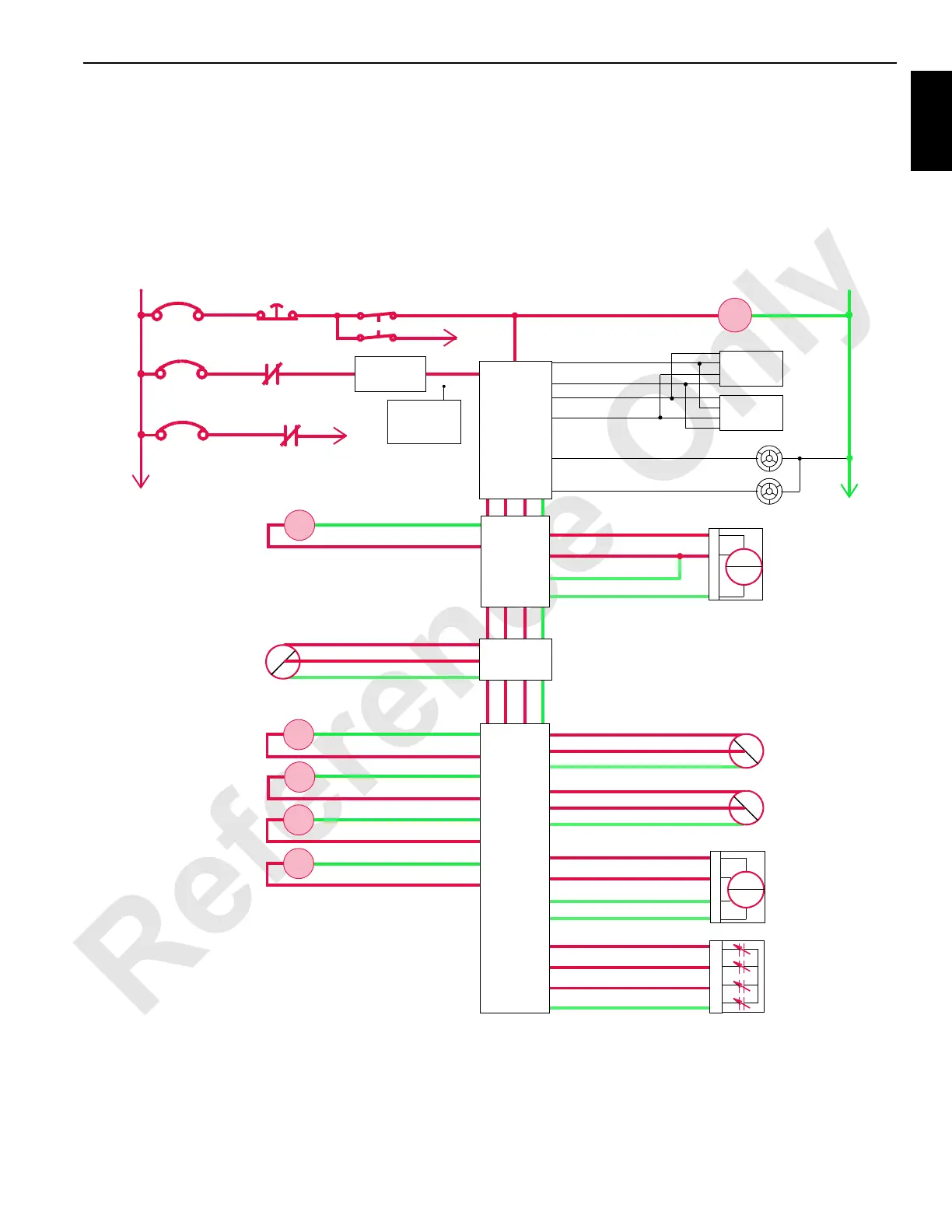

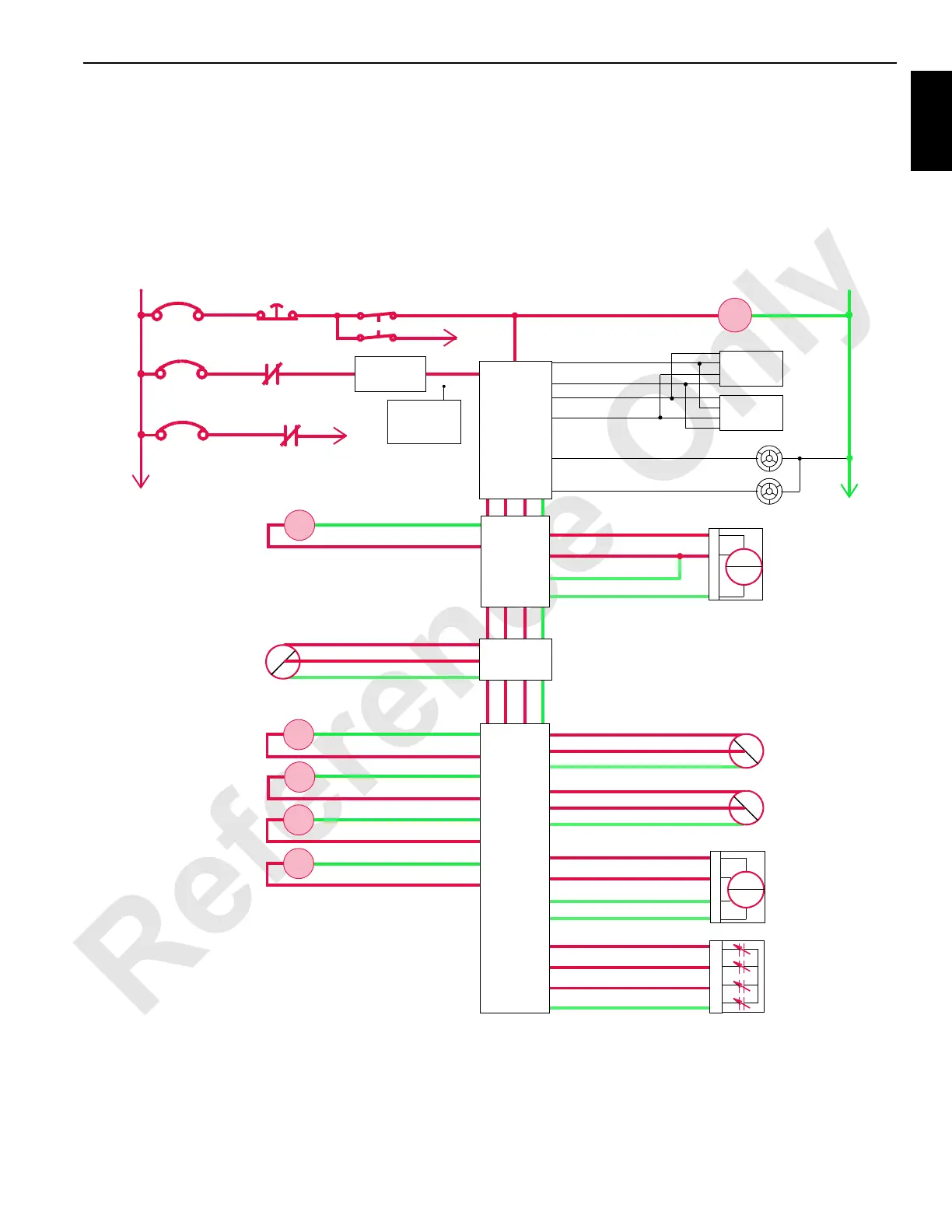

When the desired extension is reached, release the switch to

lock the cylinder in position. Hydraulic fluid at the piston end

of the cylinder counterbalance valve holds lift cylinder in the

selected position.

When the switch is released, an input signal is sent to the

Node-1 controller. The Node-7 controller sends a zero volt

output to the hydraulic solenoids HS-70 and 71 to the return

valve to the center position.

Node-3 sends a variable voltage output to the accessory

system proportional relief solenoid HS-68 to provide

approximately 207 bar (3,002 psi) system pressure.

RM-02

Counterweight Lift

Cylinder Extend

Pressure Sensor

MAX-ER Base Level

Sensor

+

–

PWR

CAB

System Fault Alarm

RCL Cab Fault Alarm

P11-07

P11-19

Display 1

Display 2

P11-01

P12-31

P12-32

P11-21

Start

WCP

CAN Power

Run 3

P12-24

Cab Power

Engine Stop

10 Amp

50 Amp

24 Volts

50 Amp

6C5A

6C5

CB7

6A

6C7

6C14

CB5

CB8

8C

8

NODE 0

NODE 1

(Master)

73-U

Counterweight Lift

Cylinder Retract

Pressure Sensor

73-E

73-a

Hyd

psi

73-V

73-A

73-c

Hyd

psi

24 Volts

AI

Gnd

24 Volts

AI

Gnd

76-a

76-E

76-S 24 Volts

AI

Gnd

76-b

AI

73-X

73-N

73-d

24 Volts

AI

Gnd

73-N

AI

Counterweight Lift

Cylinder Position

Sensor

Mag

LD

2

3

1

A

B

C

D

2

3

1

A

B

C

D

HS

72

HS

70

73-G

73-D

73-C

73-B

73-D

73-B

73-C

Counterweight Lift

Cylinder Extend

73-G

HS

73

HS

71

Counterweight Lift

Cylinder Extend

Counterweight Lift

Cylinder Retract

Counterweight Lift

Cylinder Retract

NODE 7

HS

68

Gnd 34-C

DO 34-D

Accessory System

Proportional Valve

46-g

Accessory System

Pressure Sensor

46-j

46-h

Hyd

psi

24 Volts

AI

Gnd

2

3

1

M16-12

36-m

36-J

36-k

24 Volts

AI

Gnd

36-Z

Gnd

Mast Strap

Load Pin

Load

Pin

A

B

D

NODE 3

Hand-Held

Wireless

Remote

Counterweight Lift Cylinder

DO

DO

DO

DO

Gnd

Gnd

Gnd

Gnd

NODE 4

FIGURE 1-53

Loading...

Loading...