4-75

TMS9000-2 OPERATOR MANUAL OPERATING PROCEDURES

Published 02-21-2019, Control # 611-05

section to move for the new final boom configuration of 0-0-

0-100-100).

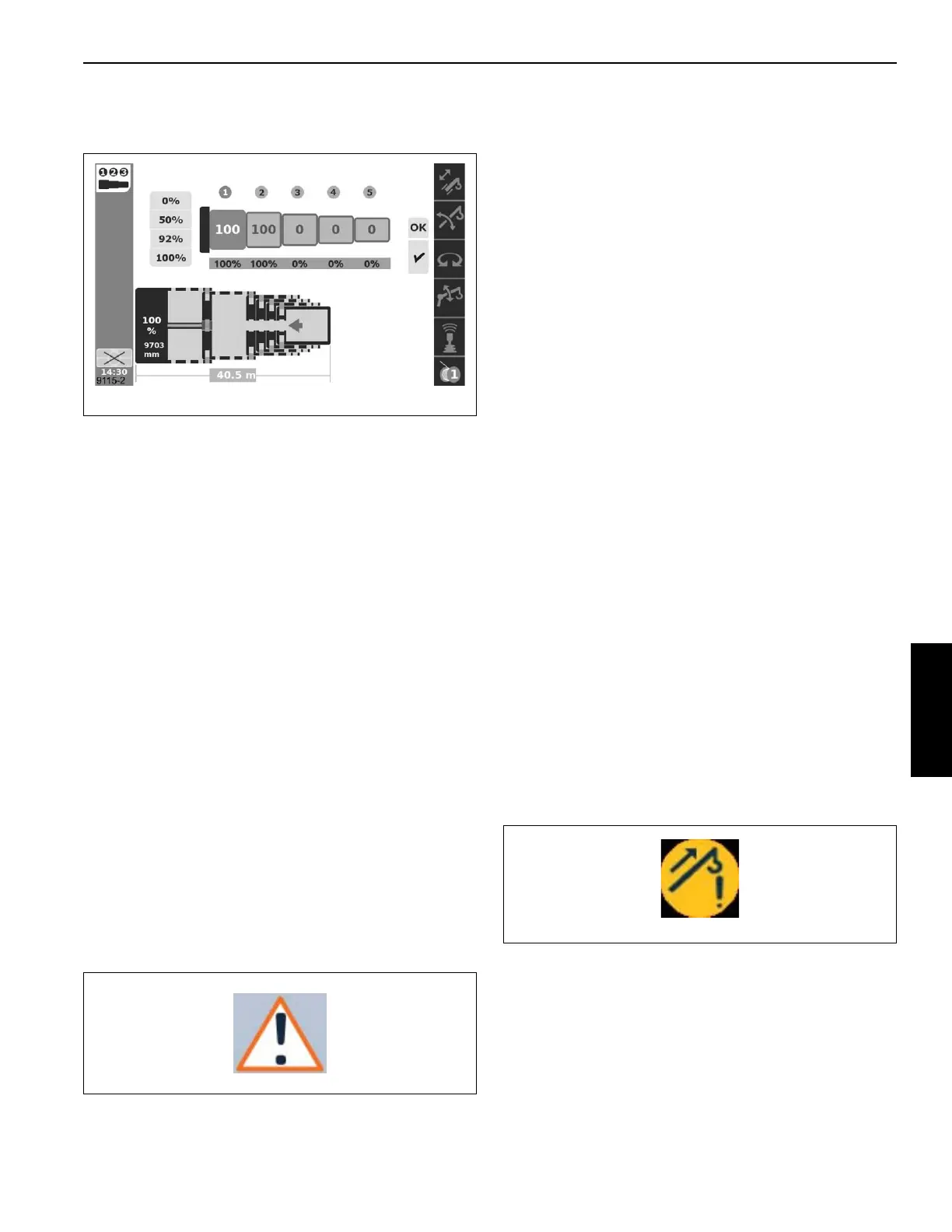

Semi-auto Mode screen refresh

When the Semi-auto screen of the operating display is

entered, the final boom configuration (“target tele picture”)

that is shown is the one most recently ACCEPTED and is

actually being used to control/operate the boom. If the

screen is exited and re-entered, what is shown may not be

the most recently REQUESTED final boom configuration.

As noted in the section of the document 'Semi-auto Mode

requiring boom to be retracted', there are cases where a

newly requested final boom configuration can not be

accepted until the current boom configuration is completed

to have the boom fully retracted. If the Semi-auto Mode is

currently requiring the boom to be retracted, and the ESC is

used to leave the Semi-auto screen, and then Semi-auto

screen is entered again, the values shown for boom sections

will revert to the original boom configuration, the ACCEPTED

boom configuration (until the boom is fully retracted and the

control system can then “shift” to the new REQUESTED final

boom configuration).

Semi-auto Mode warning indications

The control system manages a fault indication system. This

is characterized by a set of error codes or fault codes. When

a fault condition is noted by the control system, the icon in

Figure 4-145 is seen (at least in the left margin of the

operating display). There is also a screen of the operating

display that uses this icon, and that screen will show the fault

codes.

For the pinned boom control (such as in Semi-auto Mode), a

fault may be noted that is momentary. For instance, there is a

calculation of the difference between the calculated boom

length (based on the calculated boom section positions in

the control system) and the measured boom length (from the

boom outer cable reel sensor). If this difference is too large,

there is a fault condition. However, if the cable on the outer

cable reel sensor is just moved momentarily by something

near the boom, the cable may suddenly move and then

return to the proper tension. In this case, the fault condition

can appear momentarily. The icon in Figure 4-145 will

appear, and this fault code could be viewed on the operating

display, but it does not cause the telescoping function to

shut-down, and the fault code can be cleared.

For the proximity switches that sense the position of the

telescoping cylinder components and pinning mechanism,

similar momentary conditions may appear. There may also

be fault codes that appear when automated motions take

longer than expected, but the control system automatically

recovers from the condition.

For these momentary and warning conditions, the

telescoping function will continue to be available. If the left

and/or right arrows appear, then the boom can be moved in

the directions indicated by the arrows. The momentary or

warning conditions might also be helpful in diagnosing faults

that eventually cause the telescoping function to shut-down

(refer to the section in the document 'Semi-auto Mode

telescoping function shut-down'.

There are sensors in the telescoping cylinder that detect

elevated pressure conditions for extending the boom

(particularly for telescoping with significant hook loads). If the

pressure is beyond a threshold (depending on the distance

the telescoping cylinder has been extended), then the

extend motion is slowed down. If the pressure approaches

another threshold, then the extend motion is stopped. When

these conditions are apparent, the icon shown in

Figure 4-146 will be shown in the left margin of the operating

display (ODM).

Semi-auto Mode telescoping function shut-down

If the control system detects a fault that is not momentary

and not a warning indication, then the telescoping function

will be shut-down. In this case, the error icon (as seen in

Figure 4-147) will appear in the graphical schematic for the

boom (instead of the dots or the direction arrows described

previously).

Loading...

Loading...