www.mdcusa.com

Ph: 1-833-632-8721

©Copyri ght

Battery Maintenance

Proper maintenance and regular inspection of the Renogy 12V Lithium Iron Phosphate (LiFePO₄) battery is essential to ensure

optimal performance, longevity, and safety. Follow the guidelines below to maintain the battery system:

Regular Inspection

Perform routine inspections to identify and address potential issues early:

• Visual Check: Examine the battery housing and terminals for any signs of physical damage, cracks, or deformation.

• Connector Inspection: Ensure that grey 350A Anderson plugs and cable connections are secure, clean, and free of

corrosion.

• Terminal Condition: Inspect terminals for oxidation or discoloration, which may indicate overheating or poor connections.

• Cable Integrity: Check that all wiring is properly secured, undamaged, and free of exposed conductors.

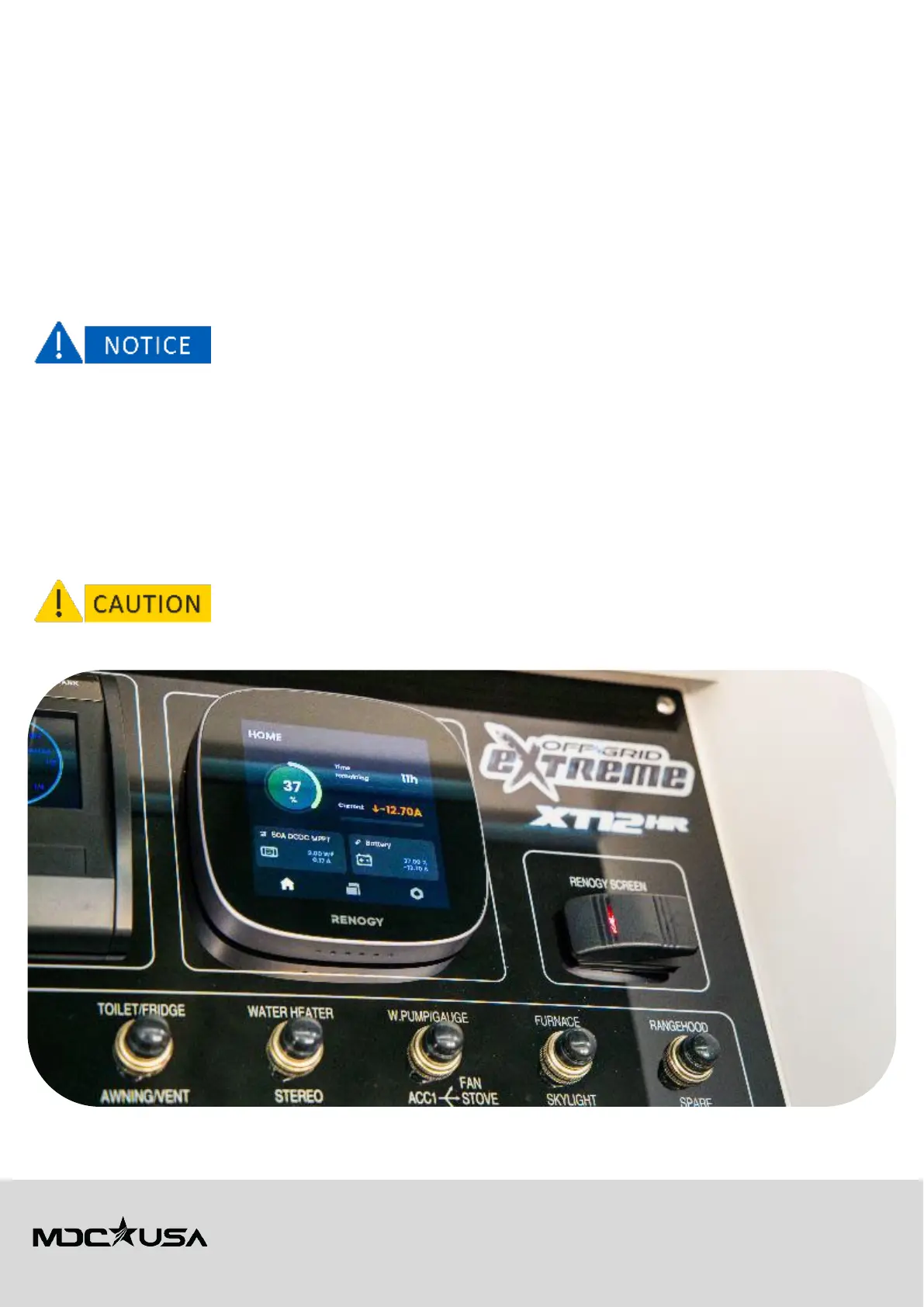

• Battery Status Indicators: Monitor the Battery Level Indicator, Battery Status Indicator, and Heater Status Indicator for

any abnormal flashing patterns.

In some applications, corrosion can form inside Anderson connectors, leading to connection failure.

Apply

dielectric grease to each connector contact periodically

to repel moisture and prevent corrosion

Cleaning the Battery

To keep the battery clean and in good working order, follow these steps:

1. Turn off the battery by pressing and holding the Power Button for 3 seconds.

2. Disconnect the battery from the system, including the grey 350A Anderson plugs and any connected cables.

3. Remove debris such as leaves, dust, or dirt from around the battery compartment.

4. Wipe down the battery housing with a soft, lint-free cloth. If necessary, dampen the cloth with water or mild soap and water

for tougher dirt.

5. Dry the battery completely using a clean, dry cloth before reconnecting it to the system.

6. Reconnect the battery and ensure all connections are secure before turning it back on.

DO NOT use abrasive cleaners, solvents, or high-pressure water, as these may damage the battery

housing or electrical contacts

Loading...

Loading...