MC2000 – Assembly Instruction Manual

4

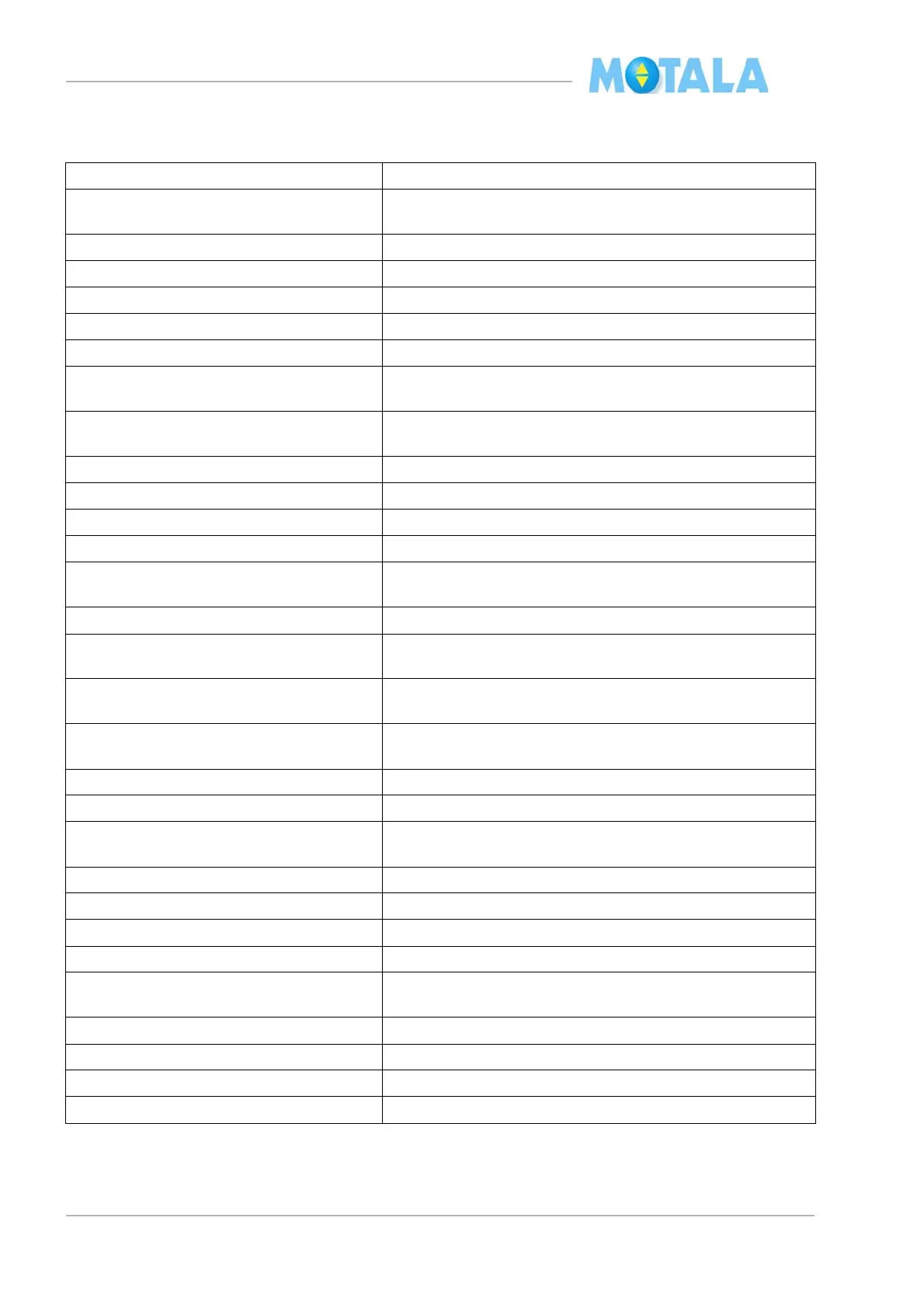

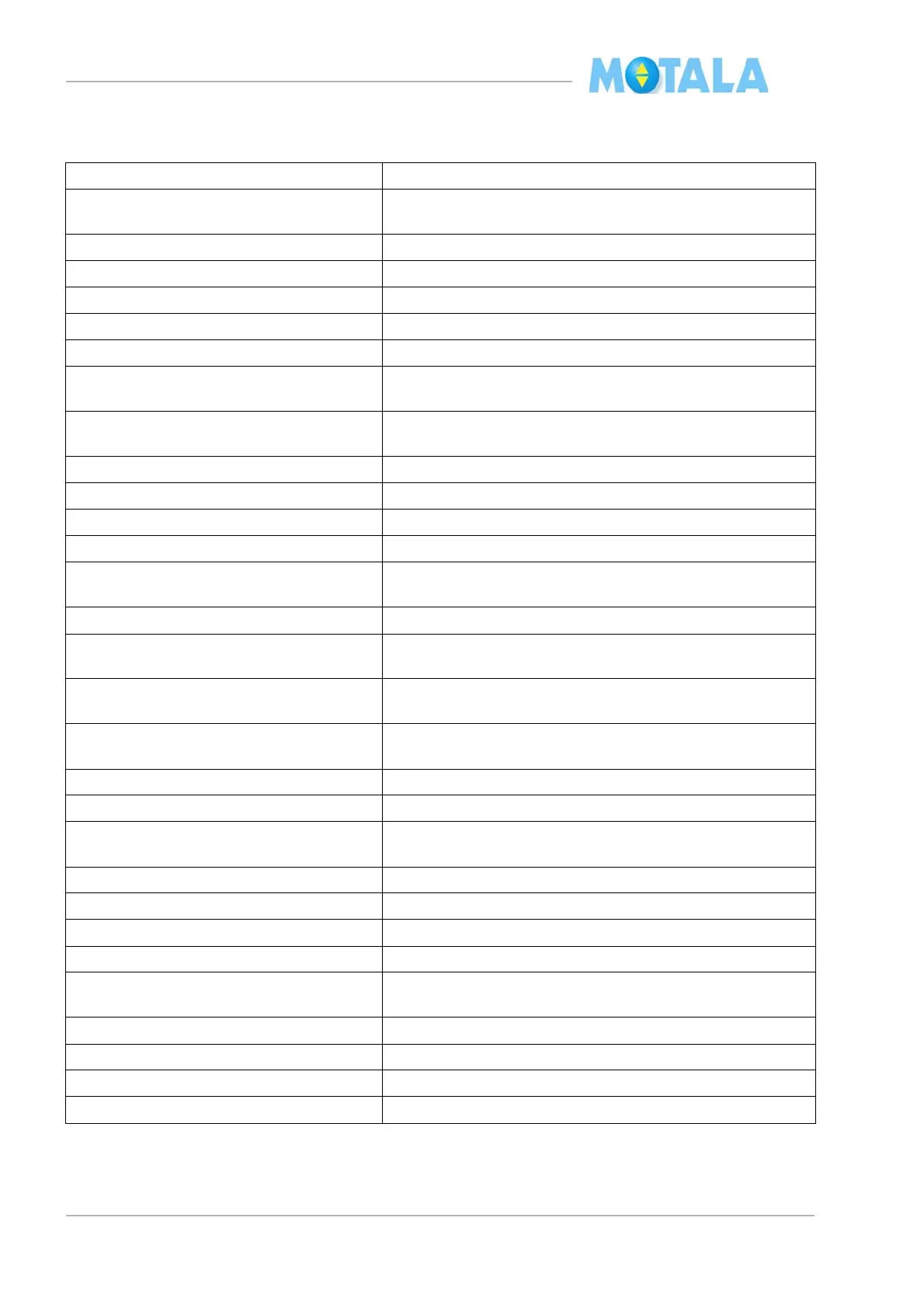

Wordlist

Adjacent lift Lift with door or doors on sides B or D.

Chain joint For connecting the chain between the guide rail sections and

be

tween the chain and the jointing rod.

Clamp coupling For jointing the driving shaft.

Corner profile 100x40 Non-drive side corner.

Corner profile 250x40 Drive side corner.

Door front (With door frame, lock etc).

Drive command box For temporary driving.

Drive command panel Plate with control buttons, attached to the panel shelf and

t

he panel plate.

Drive side The side where the guide rails are placed. This is the wider

s

ide if you look at the door frame. Can be on the B or D side

FF Finished floor.

Glass module Glass module on the long and short sides.

Jointing rod 12x12 mm square rod for adjusting the chain tension.

Jointing sleeve U-section to be put between two corner profiles.

Lift well module Isolamine. Product and expression for 25 to 35 mm thick iso-

lated steel modules.

Non-drive side E.g. side B if the guide rails are on side D.

Panel plate The plate to which the panel shelf and the control panel are

att

ached.

Panel shelf Steel shelf with electric equipment, attached to the panel

pl

ate.

Passage contact Contact which straps across the lock contact when the lift is

in

the landing zone.

Platform Floor frame, floor plate

Pit prop (in the pit) Yellow safety bar that can be raised.

Safety gear test equipment. Attached below the gripping lever. Remote-released by a

c

ord in the control panel.

Side A The side where the motor and gear are placed.

Side B The side placed clockwise next to side A.

Side C The side opposite side A.

Side D The side placed clockwise next to side C.

Slide Flat bar iron with sliding guide shoes where the chain is fas-

tened.

Turning case Cut plastic case where the chain changes direction.

Two-entrance lift. Lift with doors on side A and side C.

Two-metre fixing plate angles. Fixings for the large cover plate above the guide rails.

Work platforms Occasional platforms for building lift wells.

Loading...

Loading...