7

MC2000 – Assembly Instruction Manual

Assembly

Introduction

General information on how to erect modules

Lift well modules

Glass modules

Construction of precision gauge blocks

This section contains general information on

how t

o construct so called precision gauge

blocks and how to erect lift well modules and

glass modules.

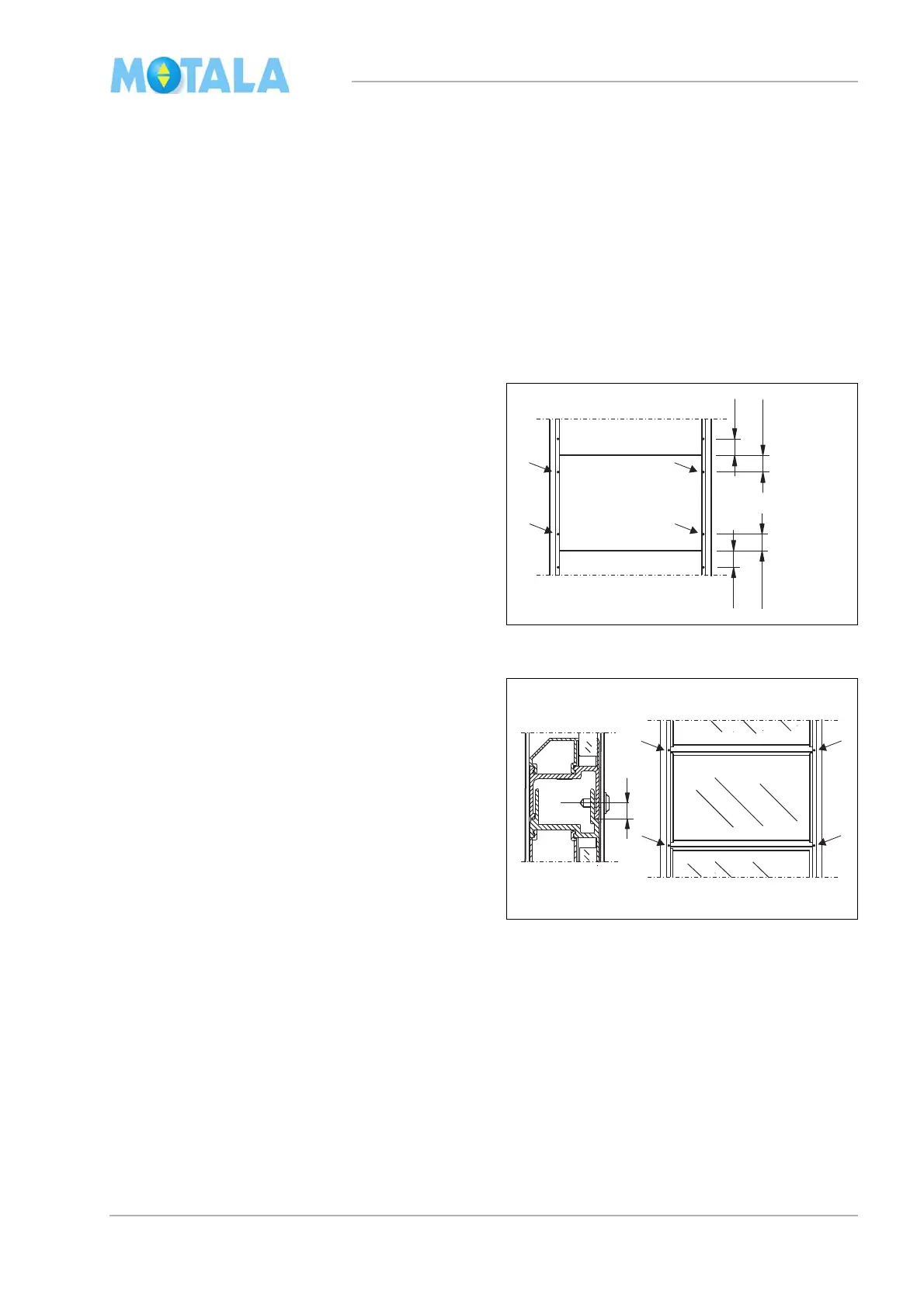

Generally, each module is assembled with four

scr

ews in the corner profiles. The screws are

placed about 100 mm from the upper and lower

edges.

For a nicer look, the screws can be exchanged

by

pop rivets (4 mm).

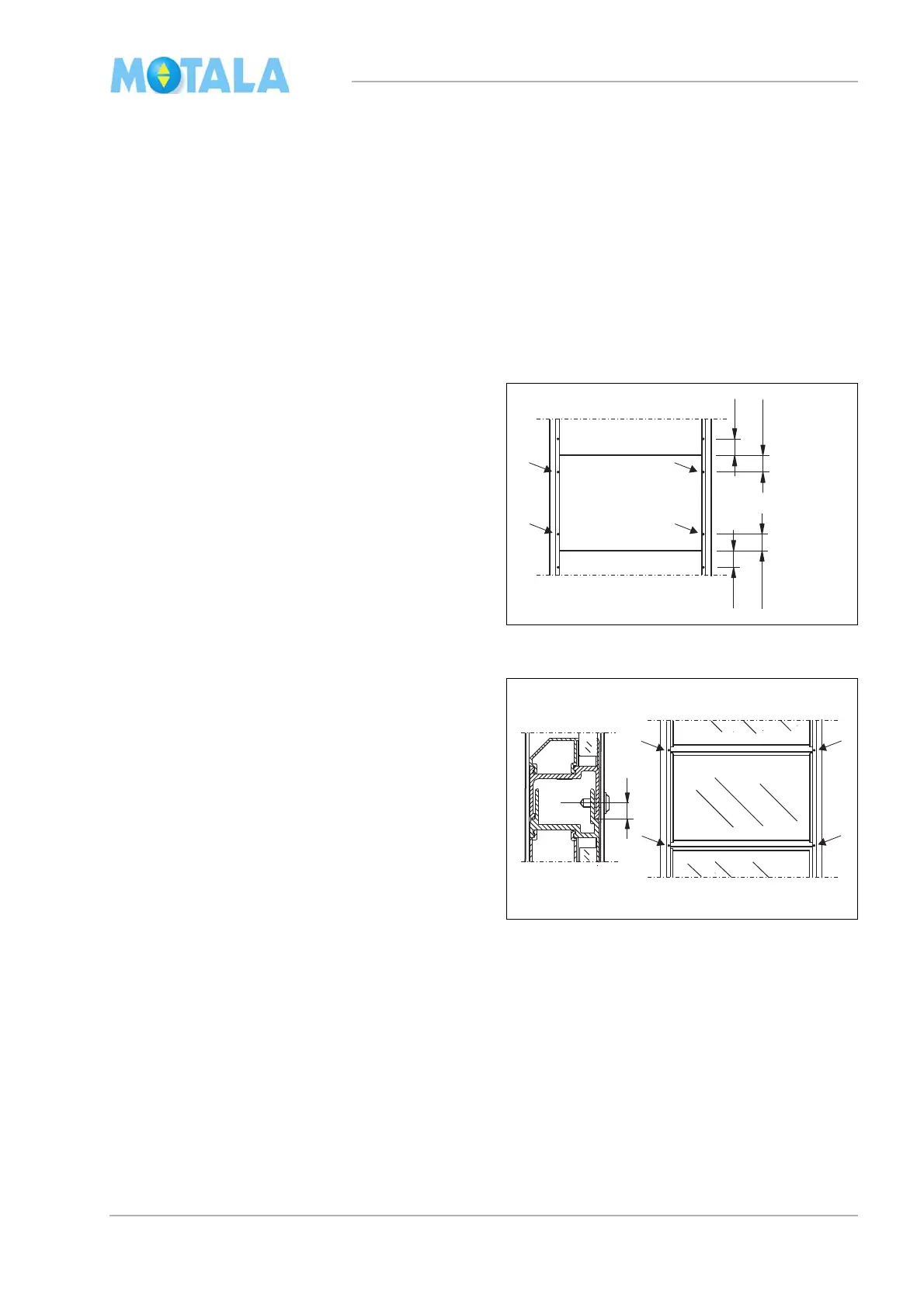

Glass modules are to be placed with the bevel-

led window moulding on the outside of the lift

well

. (The flush side on the inside.)

The modules are generally put together so that

each modul

e is fastened with four screws in the

corner profiles. You need to pre-drill 3,2mm.

The screws in the splice between two modules

are

placed about 8 mm from the lower edge of

the upper module so that the screw also goes

through the male profile of the lower module.

For glass modules, precision gauge blocks are

used at joist passages and in the pit so that the

glass surfaces are placed at the proper height

according to the layout drawing. Note that the

measurements in the layout drawing apply to

cutting measurements of the precision gauge

blocks. Example: see the heading “Layout

drawing” on page 48

Loading...

Loading...