L

--

740

--

28

--

E

●

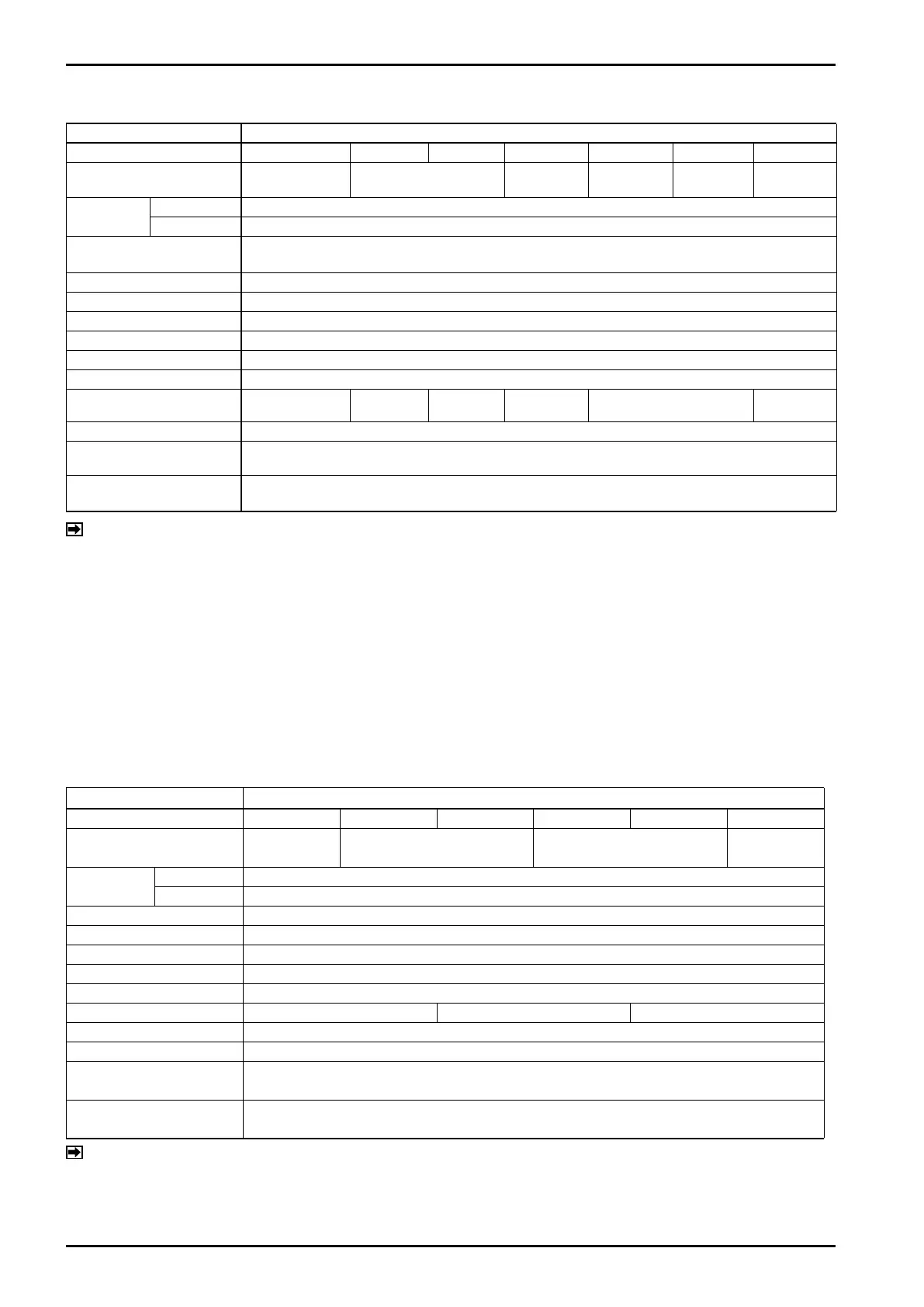

CA006 to CA080

Item Description

Model CA006 CA010 CA015 CA025 CA040 CA050 CA080

Nominal flange size

10mm, 3/8"(※1),

DN15

15mm, 1/2", DN15

25mm, 1",

DN25

40mm, 1・1/2",

DN40

50mm, 2",

DN50

80mm, 3",

DN80

Materials

Wetted parts SUS316L, SUS316 + Alloy C, Alloy C

Housing SUS304

Process connection

JIS 10, 20, 30, 40, 63K RF / ASME (JPI) 150, 300, 600 RF

DIN PN 10, 16, 25, 40 RF(※2), IDF ferrule (※3), screw-in

Acceptable fluids Liquid and gas

Density range 0 to 2.0g/mL

Viscosity range

Max.10000mPa・s

(※4)

Temperature range

Separately mounted:

-

200 to +200℃, Integrally mounted:

-

200 to +150℃ (※5) (※6)

Tube withstands (at 20°C) 9.4MPa (※7)

Max. operating pressure Varies according to process connection.

Sensor housing withstands

(MPa). (※8)

3.8 3.0 2.2 1.6 1.8 1.4

Flow direction Forward / Reverse

Explosionproof

configuration

Refer to section 10.4

Dusttight, waterproof

configuration

IP66 / 67

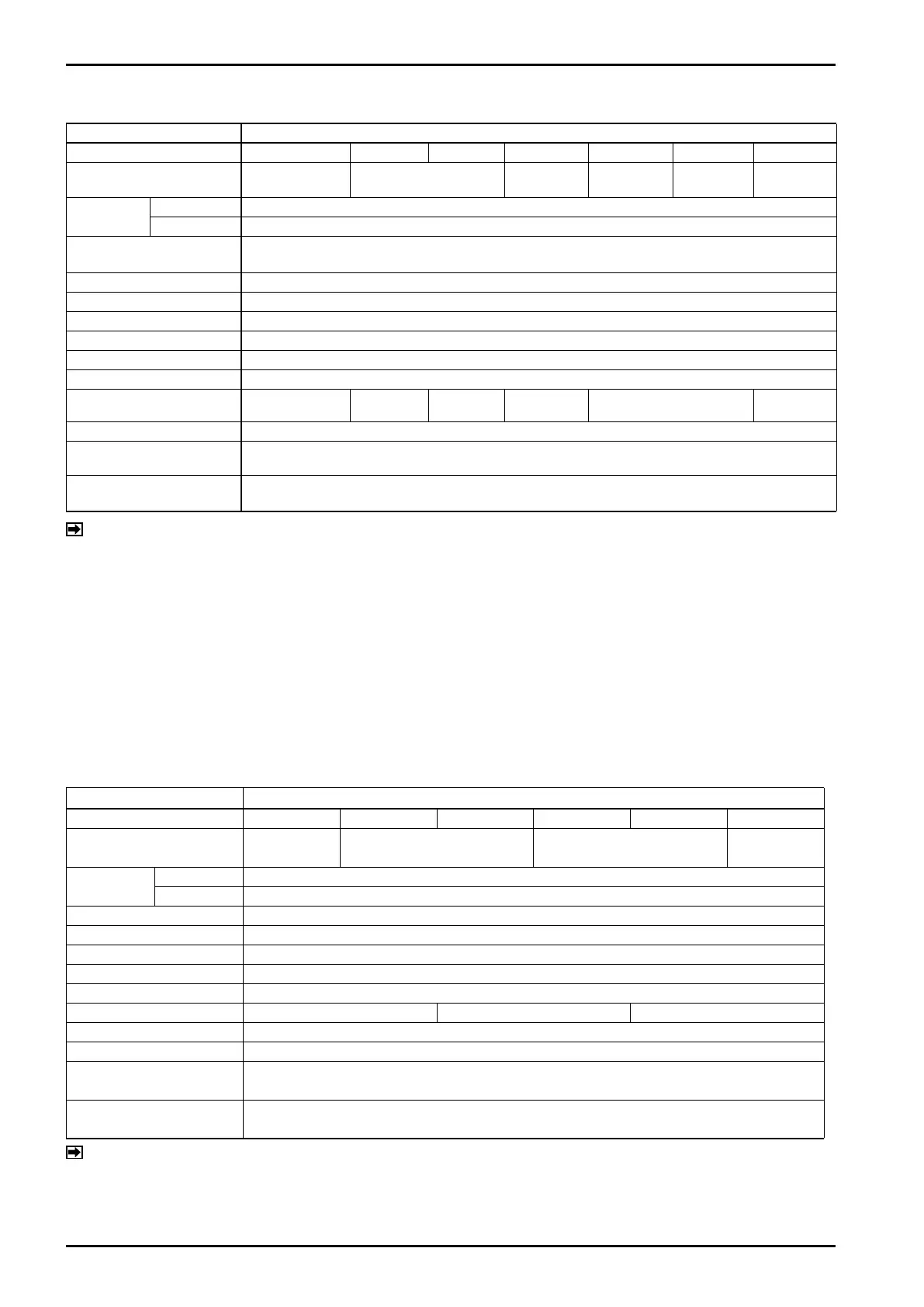

●

CA100 to CA250

Item Description

Model CA100 CA150 CA15H CA200 CA20H CA250

Nominal flange size

100mm, 4",

DN100

150mm, 6", DN150 200mm, 8", DN200

250mm, 10",

DN250

Materials

Wetted parts

SUS316L

Housing SUS304

Process connection JIS 10, 20, 30, 40K RF / ASME (JPI) 150, 300, 600 RF/ DIN PN 10, 16, 25, 40 RF

Acceptable fluid

Liquid

Density range

0.3 to 2.0g/mL

Viscosity range

Max.10000mPa・s

(※1)

Temperature range

Separately mounted:

-

200 to +200℃, Integrally mounted:

-

200 to +150℃ (※2) (※3)

Tube withstands (at 20°C) (※4)

13.56MPa 10.6MPa 8.8MPa

Max. operating pressure

Varies according to process connection.

Flow direction

Forward / Reverse

Explosionproof

configuration

Refer to section 10.4

Dusttight, waterproof

configuration

IP66 / 67

NOTES ※1: 1/2" for ASME and JPI flanges.

※2: DIN franges are available only to meters of the wet part material, "SUS316L"and"SUS316L+Alloy C".

※3: For application to foods, this product does not comply with CE marking.

※4: If the viscosity is 10000mPa·s or more, contact OVAL.

※5: Refer to section 10.4 for explosionproof specification.

Refer to section 10.5 for the ambient temperature.

※6: In case of PED specification, the minimum temperature lower limit is -196℃.

※7: Refer to section 3.1.5 for PED specification.

※8: This pressure does not represent the rated test pressure of a pressure vessel, but 1/4 of the breakdown test

pressure at OVAL (distorted enclosures do not constitute a failure of the test), or the data obtained from the FEM

analysis, whichever is lower (or safer).

※: For availability of high pressure gas safety regulation compliant and CE mark compliant products, consult the

factory.

NOTES ※1:

If the viscosity is 10000mPa·s or more, contact OVAL.

※2: Refer to section 10.4 for explosionproof specification.

Refer to section 10.5 for the ambient temperature.

※3: In case of PED specification, the minimum temperature lower limit is -196℃.

※4: Refer to section 3.1.5 for PED specification.

※: For products that are compliant with the High Pressure Gas Safety Act, consult OVAL.

Loading...

Loading...