L

--

740

--

28

--

E

●

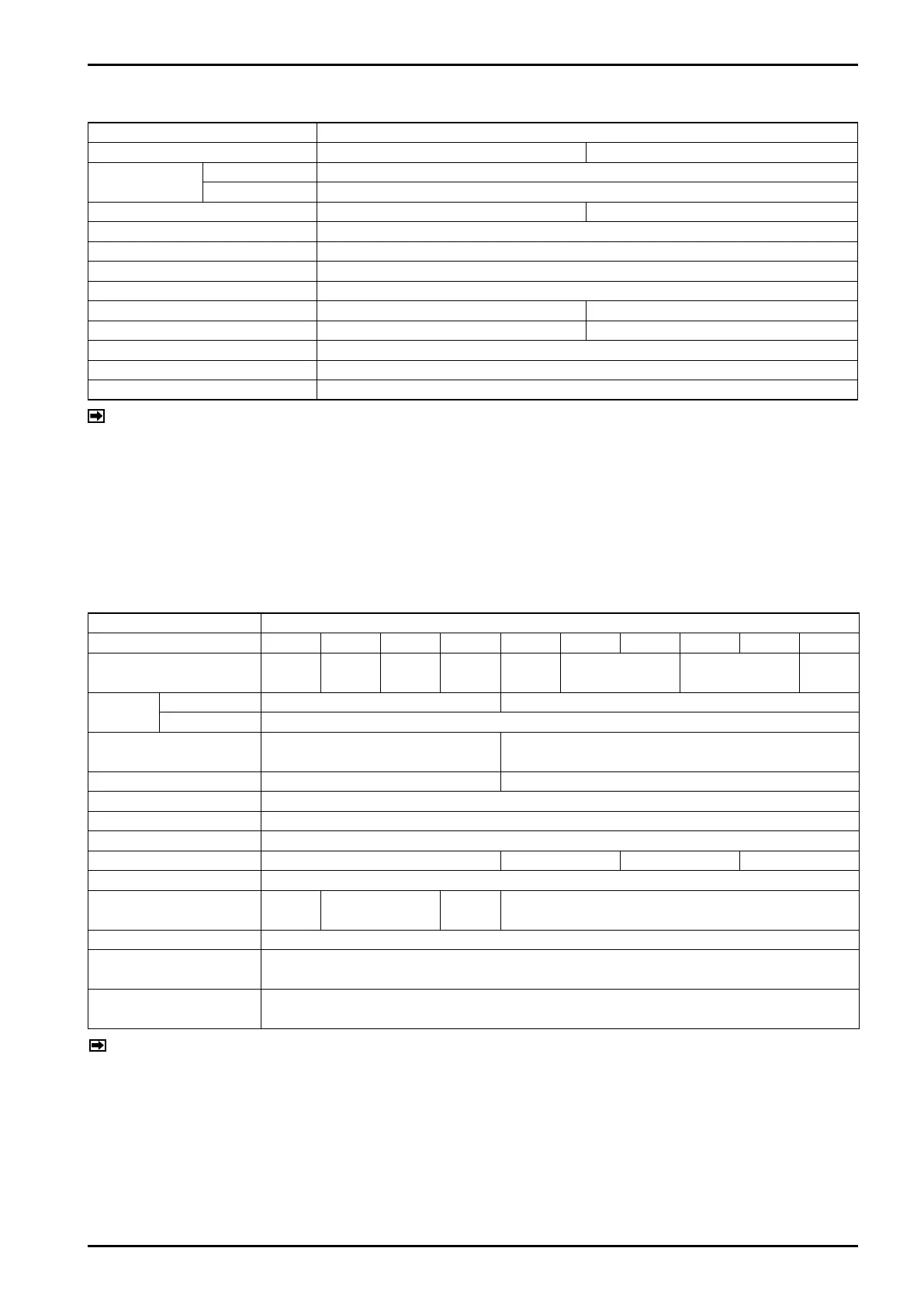

High pressure service models (CA010 and CA015)

Item Description

Model CA010 (high pressure service) CA015 (high pressure service)

Materials

Wetted parts Flow tube: Alloy C, Manifold: Equivalent to Alloy C (CX2MW)

Housing SUS304

Process connection Screw-in Rc 3/8 Screw-in Rc 3/4

Acceptable fluids Liquid and gas

Density range 0.3 to 2.0g/mL

Viscosity range Max.10000mPa・s (※1)

Temperature range

Separately mounted :

-

200 to +200℃, Integrally mounted:

-

200 to +150℃ (※2) (※3)

Max. operating pressure 36MPa at room temperature 43MPa at room temperature

Sensor housing withstands (※3) 3.0MPa 2.2MPa

Flow direction Forward / Reverse

Explosionproof configuration Refer to section 10.4

Dusttight, waterproof configuration IP66 / 67

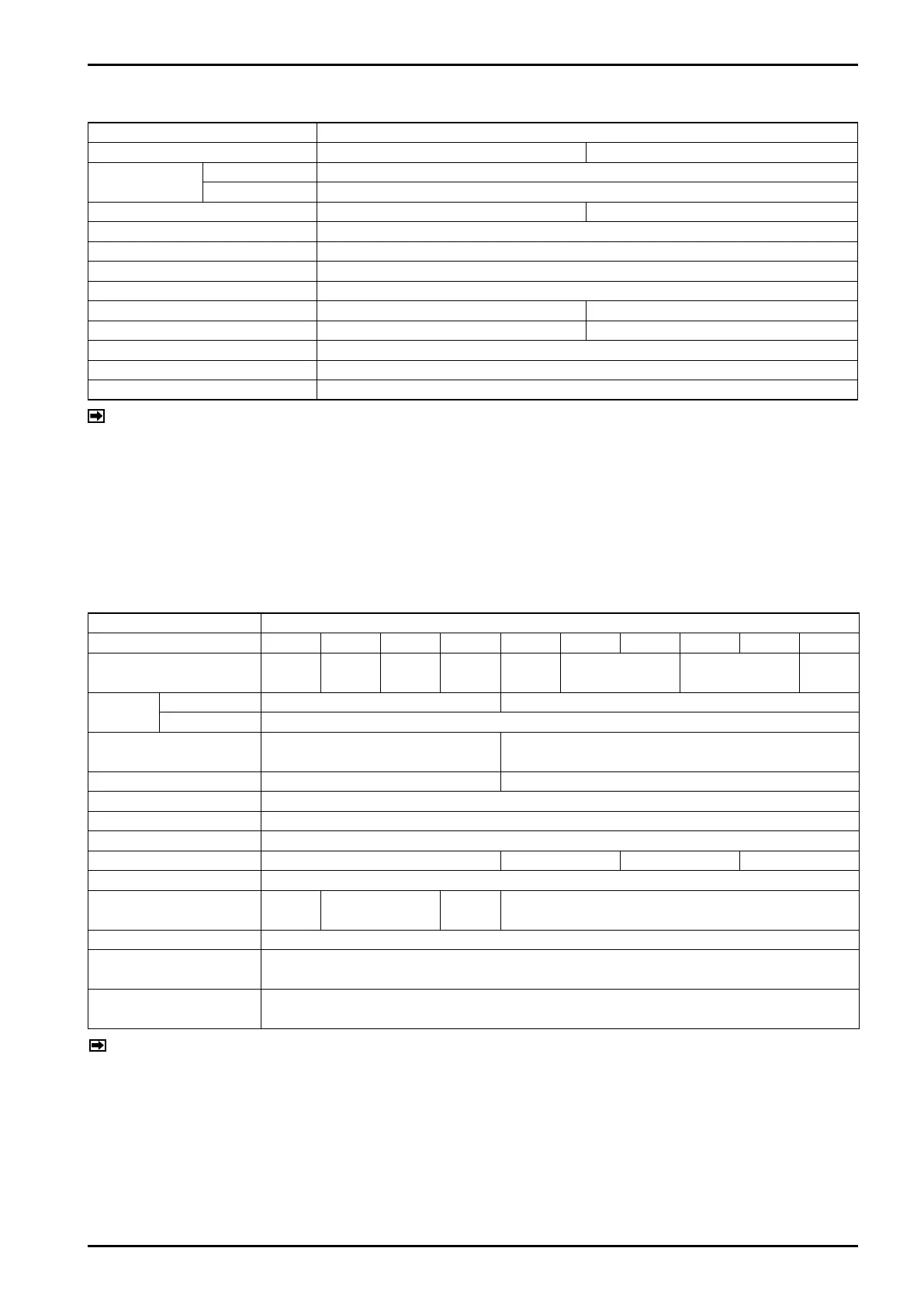

●

Low temperature explosionproof service models (CA025 to CA250)

Item Description

Model

CA025 CA040 CA050 CA080 CA100 CA150 CA15H CA200 CA20H CA250

Nominal flange size

25mm, 1",

DN25

40mm, 1・1/2",

DN40

50mm, 2",

DN50

80mm, 3",

DN80

100mm, 4",

DN100

150mm, 6", DN150 200mm, 8", DN200

250mm, 10",

DN250

Materials

Wetted parts SUS316L, SUS316 + Alloy C,Alloy C SUS316L

Housing SUS304

Process connection (※1)

JIS 10, 20, 30,40,63K RF / ASME (JPI) 150, 300, 600 RF

DIN PN 10, 16, 25, 40 RF (※2), IDF ferrule (※3)

JIS 10, 20, 30K RF / ASME (JPI) 150, 300, 600 RF

DIN PN 10, 16, 25, 40 RF (※2)

Acceptable fluids Liquid and gas Liquid

Density range 0.3 to 2.0g/mL

Viscosity range Max.10000mPa・s

Temperature range

-200 to +50℃ (Separately mounted only) (※4)

Tube withstands 9.4MPa (at 20℃)

13.56MPa (at 20℃) 10.6MPa (at 40℃) 8.8MPa (at 40℃)

Max. operating pressure

Varies according to process connection.

(※5)

Sensor housing

withstands (※6)

1.6MPa 1.8MPa 1.4MPa

—

Flow direction Forward / Reverse

Explosionproof

configuration

Refer to section 10.4

Dusttight, waterproof

configuration

IP66 / 67

NOTES

※1: When "SUS316L" or "SUS316L + Alloy C" is selected for the materials of wetted parts, the flange material

is "SUS316". (CA025 to CA080)

※2: For the material of DIN flange, you cannot select "Alloy C".

※3: For application to foods, this product does not comply with CE marking.

※4: Refer to section 10.5 for the ambient temperature.

※5: Refer to section 3.1.5 for PED specification.

※6: This pressure does not represent the rated test pressure of a pressure vessel, but 1/4 of the breakdown test

pressure at OVAL (distorted enclosures do not constitute a failure of the test), or the data obtained from the

FEM analysis, whichever is lower (or safer).

※: For the product compliant with High Pressure Gas Safety Act or CE marking, consult us.

※: Only separately mounted transmitter is applicable.

NOTES ※1:

If the viscosity is 10000mPa·s or more, contact OVAL.

※2: Refer to section 10.4 for explosionproof specification.

Refer to section 10.5 for the ambient temperature.

※3: This pressure does not represent the rated test pressure of a pressure vessel, but 1/4 of the breakdown

test pressure at OVAL (distorted enclosures do not constitute a failure of the test), or the data obtained

from the FEM analysis, whichever is lower (or safer).

※: For products that are compliant with the High Pressure Gas Safety Act, consult OVAL.

Loading...

Loading...