Application Macros 5-1

690+ Series Frequency Inverter

5APPLICATION MACROS

The Default Application

The Inverter is supplied with 8 macros, Macro 0 to Macro 7. Each macro recalls a pre-

programmed set of parameters when it is loaded.

• Macro 0 will not control a motor. Loading Macro 0 removes all links, and sets all parameters

to the values defined for each function block in Chapter 1 “Programming Your Application”.

• Macro 1 is the factory default macro, providing for basic speed control

• Macro 2 is a set-up providing speed control with Raise/Lower Trim

• Macro 3 is for PID process control

• Macro 4 is a Speed Programmed Winder (SPW) macro.

• Macro 5 supplies speed control using preset speeds.

• Macro 6 provides for basic speed control with similar functionality to the 620 and 590+

Series Drives.

• Macro 7 is for Phase/Register applications.

How to Load a Macro

RESTORE CONFIG

This menu restores the displayed application to the drive. The

information is saved on power-down.

Also listed with your application names are the factory macros.

To restore an application see below.

RESTORE CONFIG

> APPLICATION

M

E

`UP` TO CONFIRM

menu at level 2

RESTORE CONFIG

> MACRO 1

RESTORE CONFIG

RESTORE CONFIG

Now update the non-volatile memory within the Inverter by performing a SAVE CONFIG.

Refer to the Installation Product Manual, Chapter 5: “The Operator Station” -

Saving/Restoring/Deleting Your Application

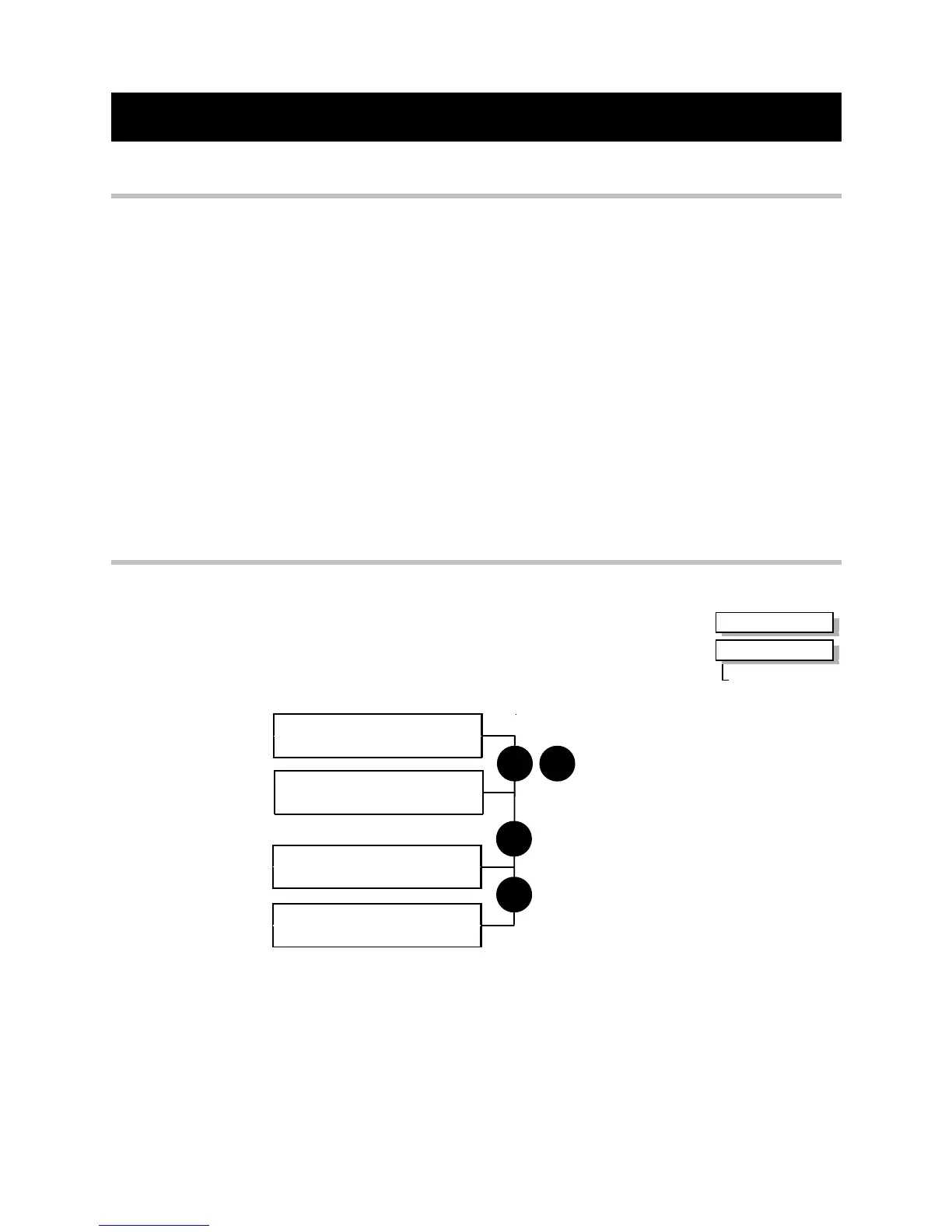

MMI Menu Map

1

SYSTEM

2

RESTORE CONFIG

RESTORE CONFIG

Loading...

Loading...