FUEL SYSTEM 20D

Note: The fuel pump can be removed from the

engine and fitted again if:

• The crankshaft is not rotated

• The drive shaft of the fuel pump is not rotated

Caution:

If the crankshaft or the pump shaft is

rotated when the pump is off the engine. Or if the

engine timing is not correct the timing of the fuel

injection pump must be checked, operation 17D-03.

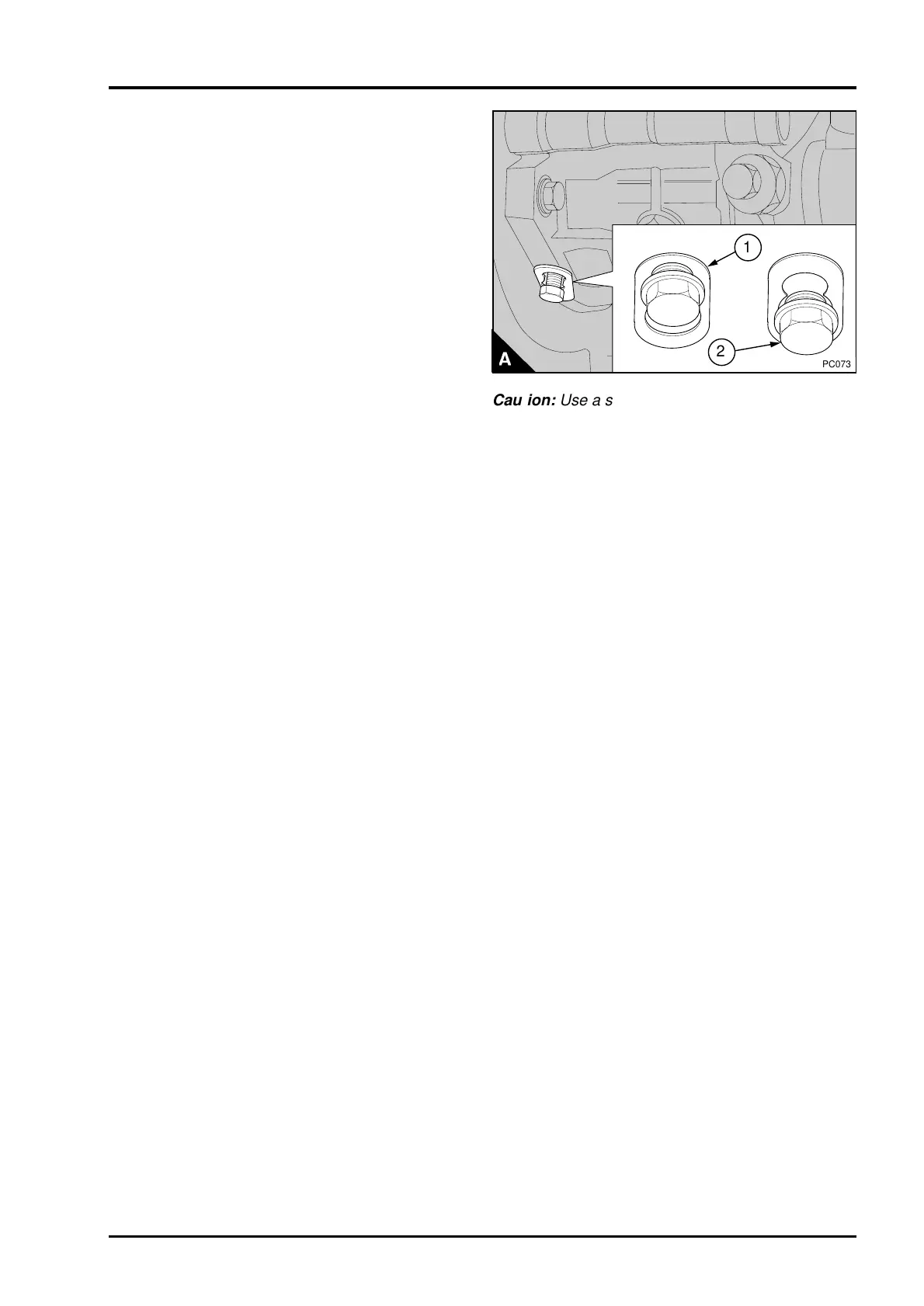

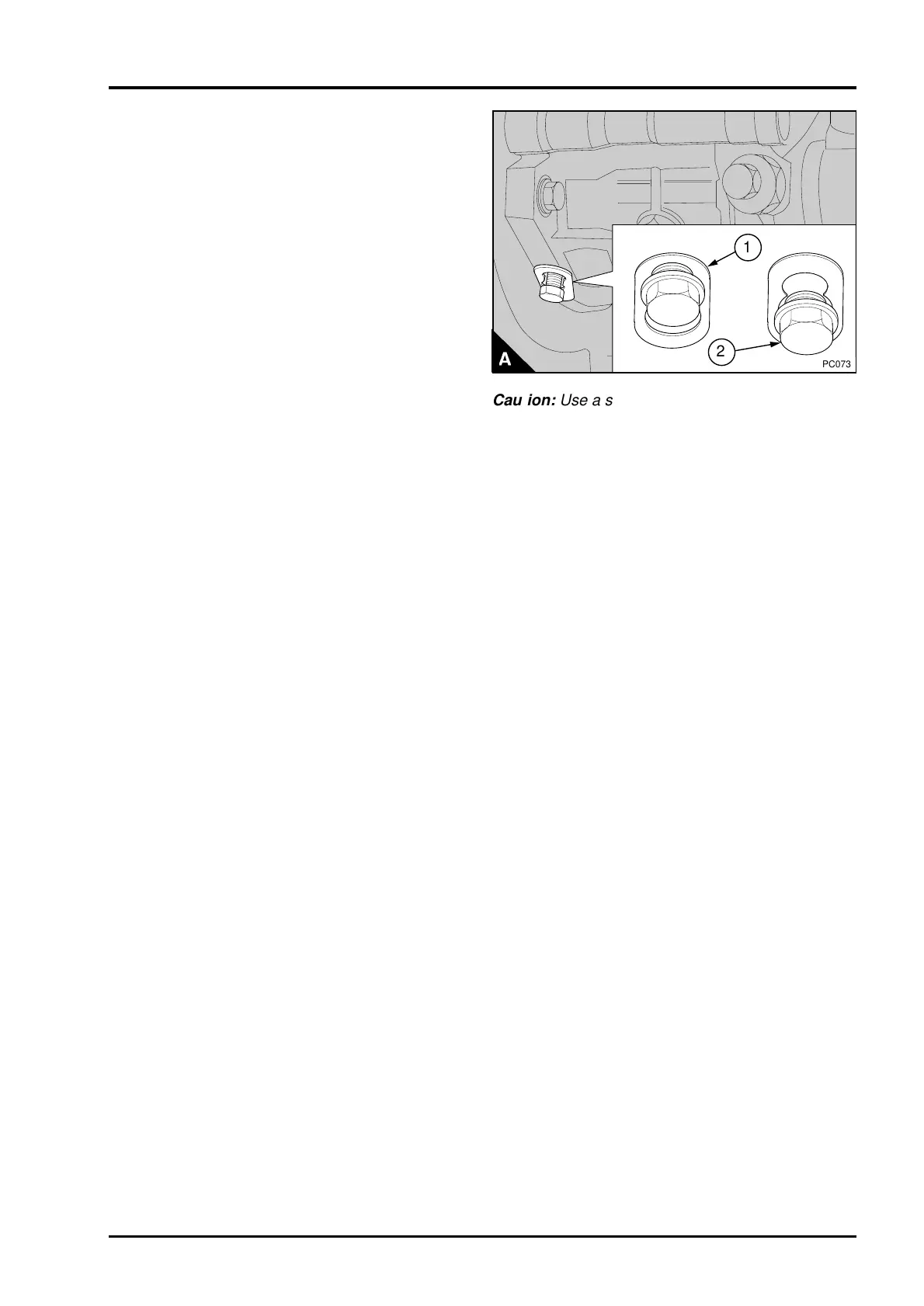

6 Release the locking screw and adjust the

spacer (A1) to enable the locking screw (A2) to be

tightened on the drive shaft of the fuel pump.

Tighten the locking screw to 12 Nm (9 lbf ft)

1,2 kgf m. Check that the spacer is free to move.

The drive shaft of the fuel pump is now

fastened.

Caution: Use a second spanner to prevent

movement of the high-pressure outlet when the

union nut for each high-pressure pipe is released.

7 Remove the pipes, the cables and the

connections for the cold start device and the

electrical stop solenoid from the fuel pump. Loosen

the nuts on the pump flange.

8 Release the setscrews and remove the gear

cover from the timing case cover. Release the nut

which retains the drive gear of the pump one to two

turns.

9 Fit the gear puller PD.155C and loosen the gear

on the drive shaft of the pump. Remove the puller,

nut and spring washer.

10 Remove the nuts from the flange of the fuel

pump and remove the pump.

To fit

1 Inspect the "O" ring and, if necessary, fit a new

"O" ring.

2 Lightly lubricate the "O" ring with clean engine

lubricating oil and put the pump into position on the

timing case. Ensure that the key is engaged

correctly in the keyway of the drive gear.

3 Fit the spring washer and the nut to retain the

drive gear. Tighten the nut to approximately 15 Nm

(11 lbf ft) 1,5 kgf m.

4 Hold the top of the pump toward the engine to

remove the backlash and fit the nuts to the pump

flange. Tighten them to 22 Nm (16 lbf ft) 2,2 kgf m.

5 Release the locking screw on the pump and

adjust the spacer (A1) to prevent the locking screw

(A2) from locking the pump shaft, tighten the

locking screw to 12 Nm (9 lbf ft) 1,2 kgf m. Check

that the spacer cannot move. The drive shaft of

the fuel pump is now free to move.

6 Fully tighten the nut for the drive gear to 80 Nm

(59 lbf ft) 8,2 kgf m. Fit the gear cover.

2

a

a

1

PC073

Caution: Use a second spanner to prevent

movement of the high-pressure outlet when the

union nut for each high-pressure pipe is tightened.

7 Fit the pipes, cables and connection for the cold

start device and electrical stop solenoid to the

pump.

8 Remove the piston position probe and fit the

atomiser together with a new seat washer. Tighten

the setscrews of all of the atomisers gradually and

evenly to 12 Nm (9 lbf ft) 1,2 kgf m.

9Eliminate air from the fuel system, operation

20D-08.

10 Fit the cylinder head rocker cover.

11

Operate the engine and check for leakage. With the

engine at the normal temperature of operation,

check that the idle speed and the maximum no load

speed are correct, operation 20D-07.

Perkins Phaser/1000 Series, April 1995 20D.03

Loading...

Loading...