12 Appendix

Page 114 Installation manual for PMCtendo DD5/PMCprimo Drive3

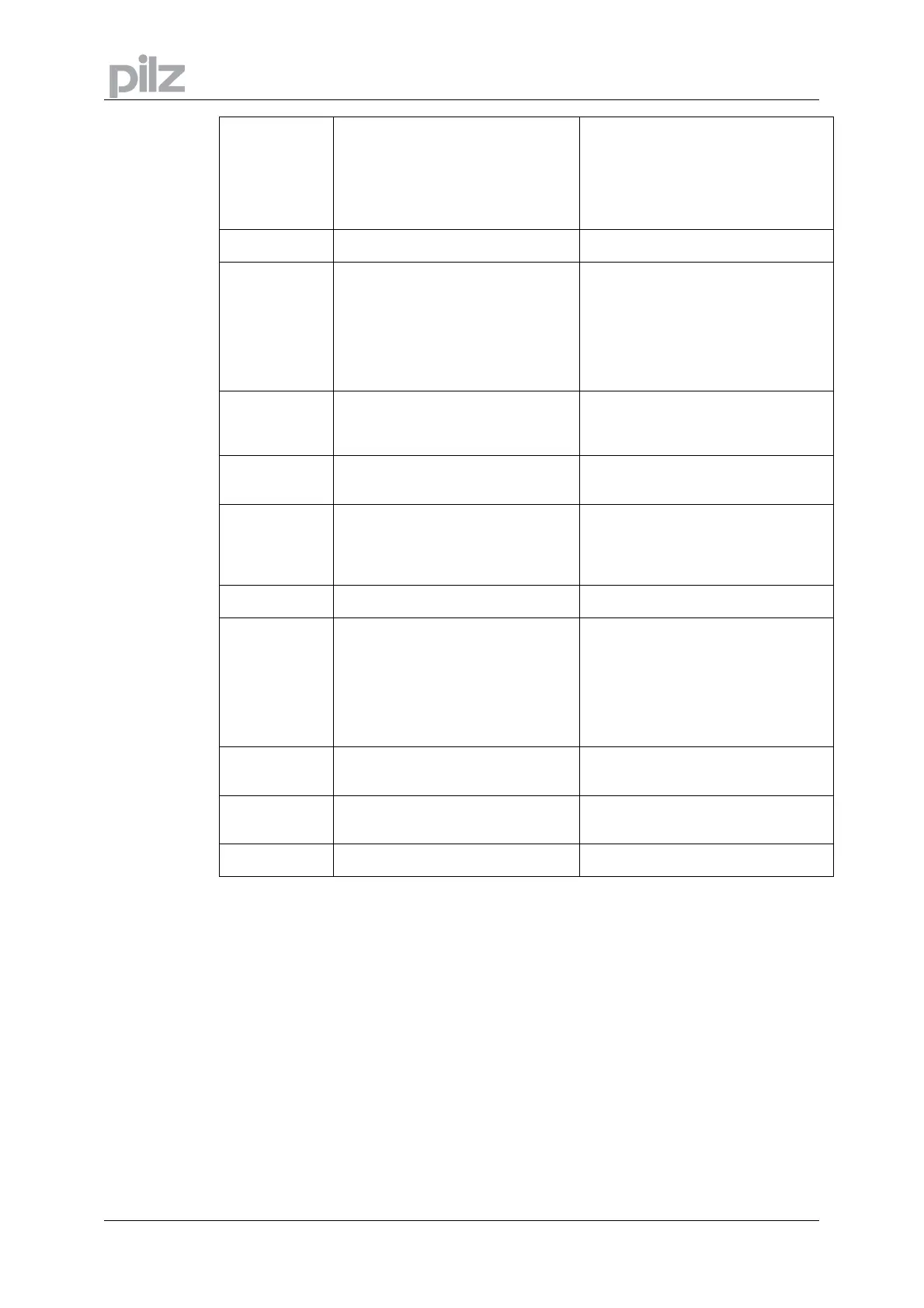

F11 message:

brake

— short-circuit in the supply cable for

the motor-holding brake

— motor-holding brake is faulty

— fault in brake cable

— no brake connected, although the

brake parameter is set to WITH

— remove the short-circuit

— replace motor

— check shielding of brake cable

— set brake parameter to “WITHOUT”

F13 message:

Internal temp.

— permissible internal temperature

has been exceeded

— improve ventilation

F14 message:

Output stage

fault

— motor cable has a short-circuit or

earth/ground short

— motor has short-circuit or

earth/ground short

— output module is overheated

— output stage is faulty

— short-circuit or short to ground in

the external regen resistor

— replace cable

— replace motor

— improve ventilation

— return the servo amplifier to the

manufacturer for repair

— remove short-circuit / ground short

F16 message:

Mains BTB/RTO

— enable was applied, although the

supply voltage was not present.

— at least 2 supply phases missed

— only ENABLE the servo amplifier

when the electrical supply voltage

has been switched on

— check the electrical supply

F17 message:

A/D converter

— error in the analog-digital conver-

sion, usually caused by EMC

interference

— reduce EMC interference check

shielding and grounding

F25 message:

Commutatiion

error

— wrong cable used

— offset is too large

— wake & shake missed

— check cable

— check resolver pole number

(RESPOLES), motor pole number

(MPOLES) and offset (MPHASE)

— execute wake & shake

F27 message:

error AS

— -AS- enable AND HW enable

have been set at the same time

— check programming and wiring of the

PLC / control system

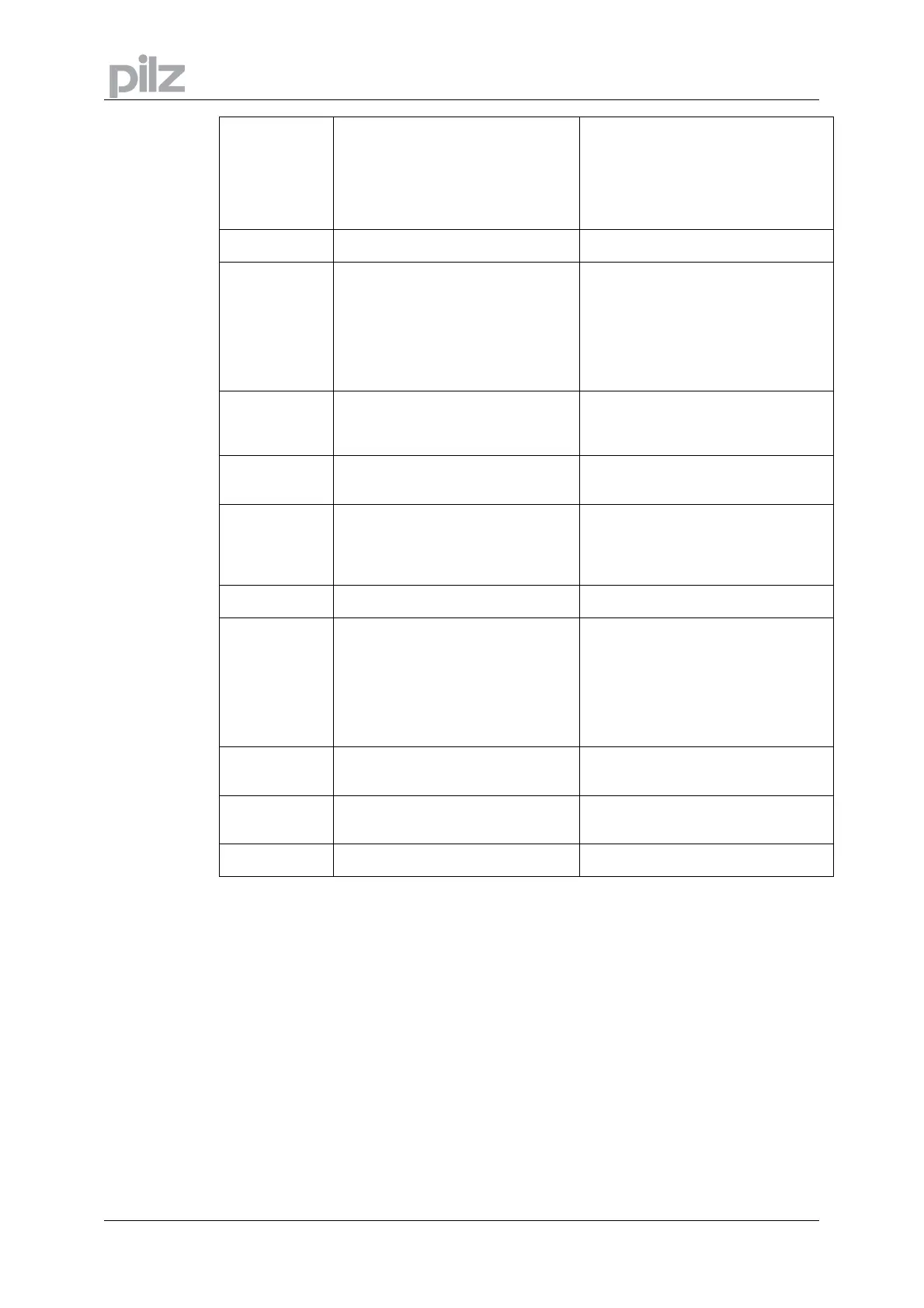

Motor does not

rotate

— servo amplifier not enabled

— software enable not set

— break in setpoint cable

— motor phases swapped

— brake not released

— drive is mechanically blocked

— motor pole no. set incorrectly

— feedback set up incorrectly

— apply ENABLE signal

— set software enable

— check setpoint cable

— correct motor phase sequence

— check brake control

— check mechanism

— set motor pole no

— set up feedback correctly

Motor oscillates

— gain is too high (speed controller)

— feedback cable shielding broken

— AGND not wired up

— reduce Kp (speed controller)

— replace feedback cable

— join AGND to CNC-GND

Drive reports

following error

— I

rms

or I

peak

set too low

— accel/decel ramp is too long

— increase I

rms

or I

peak

(keep within

motor ratings!)

— shorten ramp +/-

Motor

overheating

— I

rms

/I

peak

is set too high — reduce I

rms

/I

peak

Loading...

Loading...