PIPER AIRCRAFT, INC.

PA-28-161, WARRIOR III

MAINTENANCE MANUAL

PAGE 8

Nov 30/06

5C14

74-10-00

(c) Inspect the distributor block for cracks or other physical damage. Replace, as required.

(d) Inspect the brass electrode posts for signs of physical wear. Replace block assembly, as

required, but note that during normal operation, the post will experience an electrical-

metal transfer with the distributor gear electrode.

(e) Inspect oilite bushing for gumming oil. The bushing should be free of contamination and

the gear should turn freely in the distributor block with no appreciable drag. If the bushing

is gummed, wipe the bushing with MEK and lubricate with one drop of Exxon Teresstic

100 or Slick P/N M-3306. No other oils should be placed in these bushings.

(f) Ensure the distributor block surfaces are free of all oil and carbon dust prior to

reassembly.

(g) Inspect distributor gear teeth for wear and general integrity. Replace block assembly as

required.

(h) Inspect the electrode finger for looseness. The electrode should be held securely to the

shaft when tested with light finger pressure. If loose, replace block and gear.

(i) Clean the end of the electrode to remove

electrical deposits.

(j) Inspect bearing bar for cracks or other physical

damage. Replace as required.

(k) Ensure the bearing bar is free of all and carbon

dust prior to reassembly.

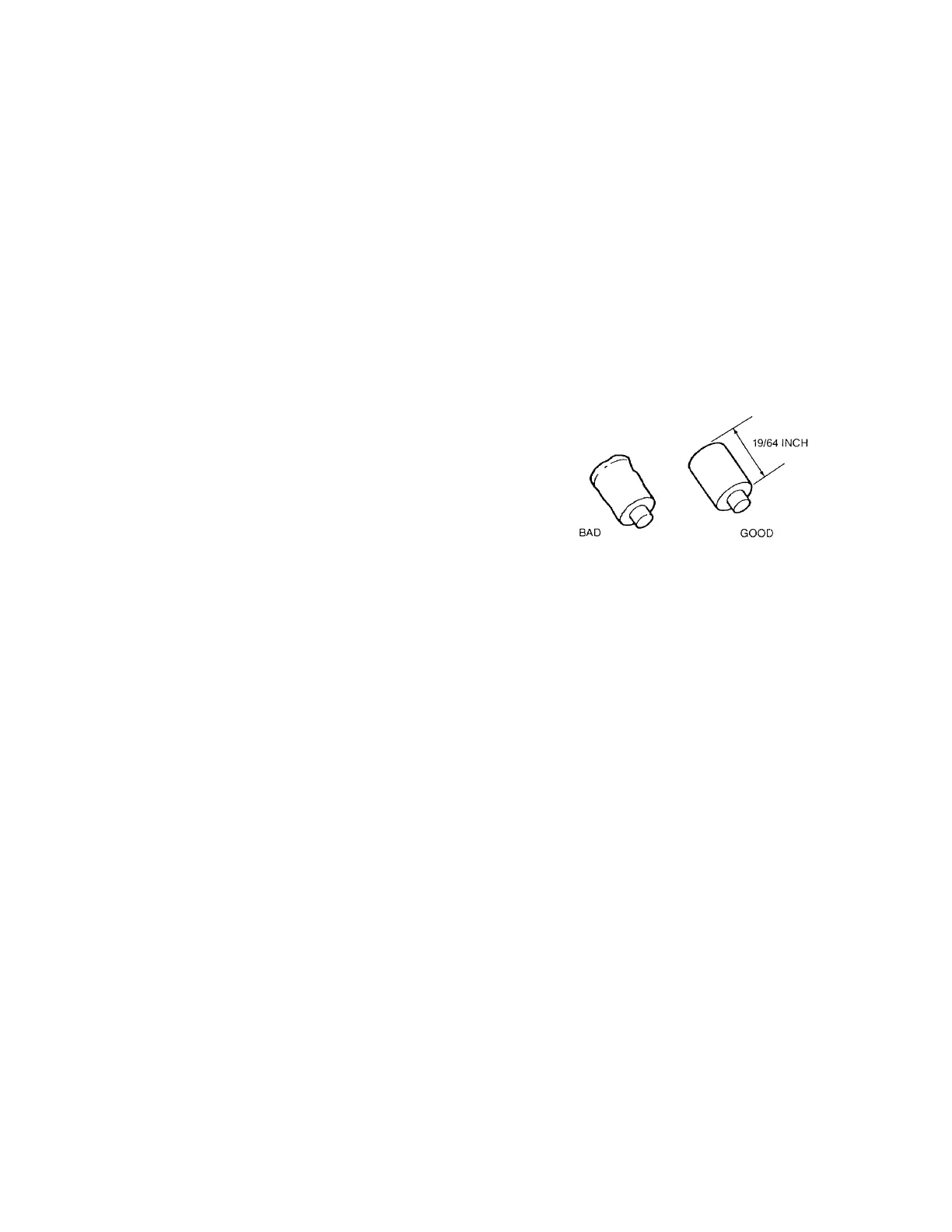

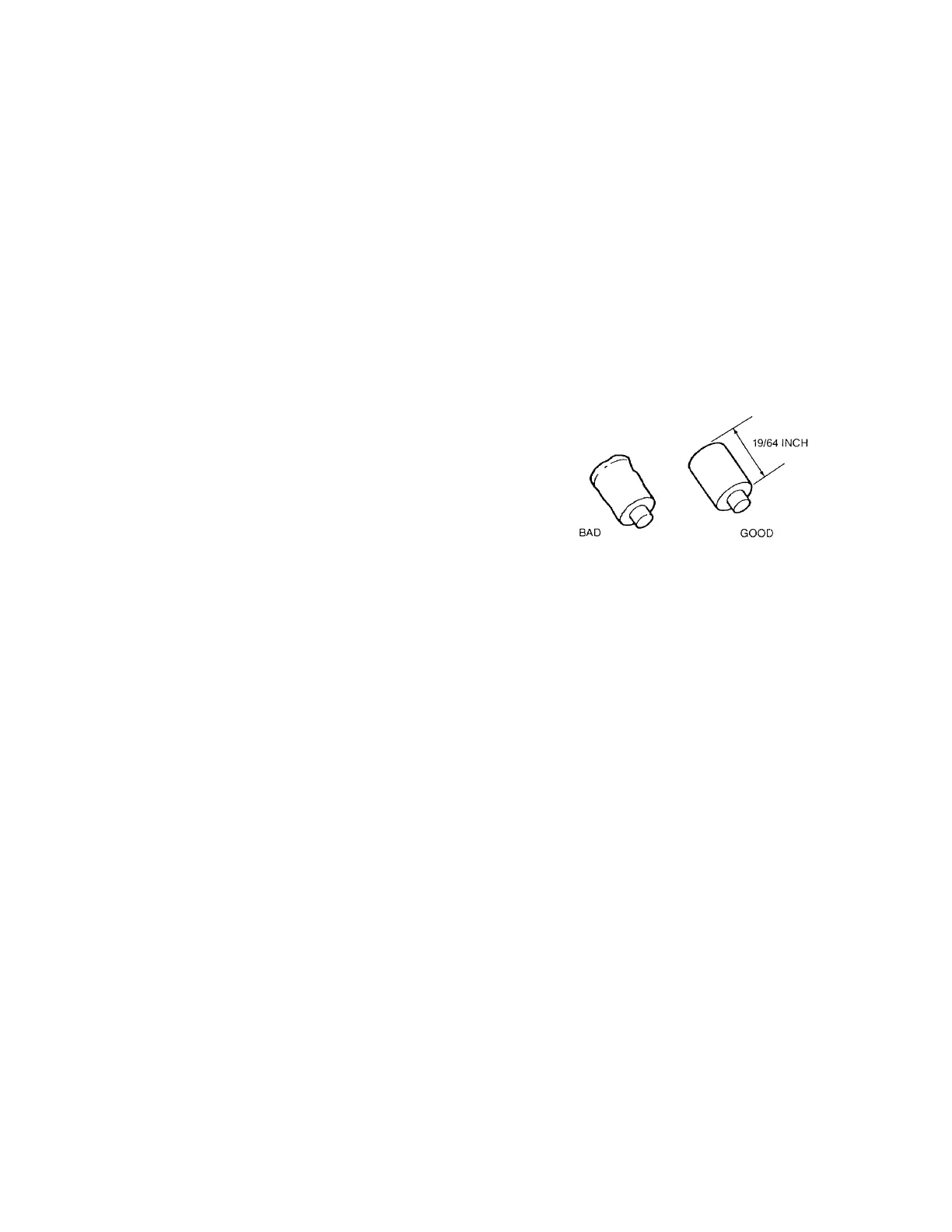

(9) Inspect the carbon brush. Overall length must be

greater than 19/64 (.297) inch and the outside

diameter must be uniform (see Figure 7). Replace as

required.

(10) Inspect the loading spring. Overall free standing length should be greater than 19/32 (.594)

inch. Springs that appear worn, that have flat spots or are too short must be replaced.

Carbon Brush Assembly

Figure 7

Loading...

Loading...