Section 03 ENGINE

Sub-Section 05 (TOP END)

03-05-14

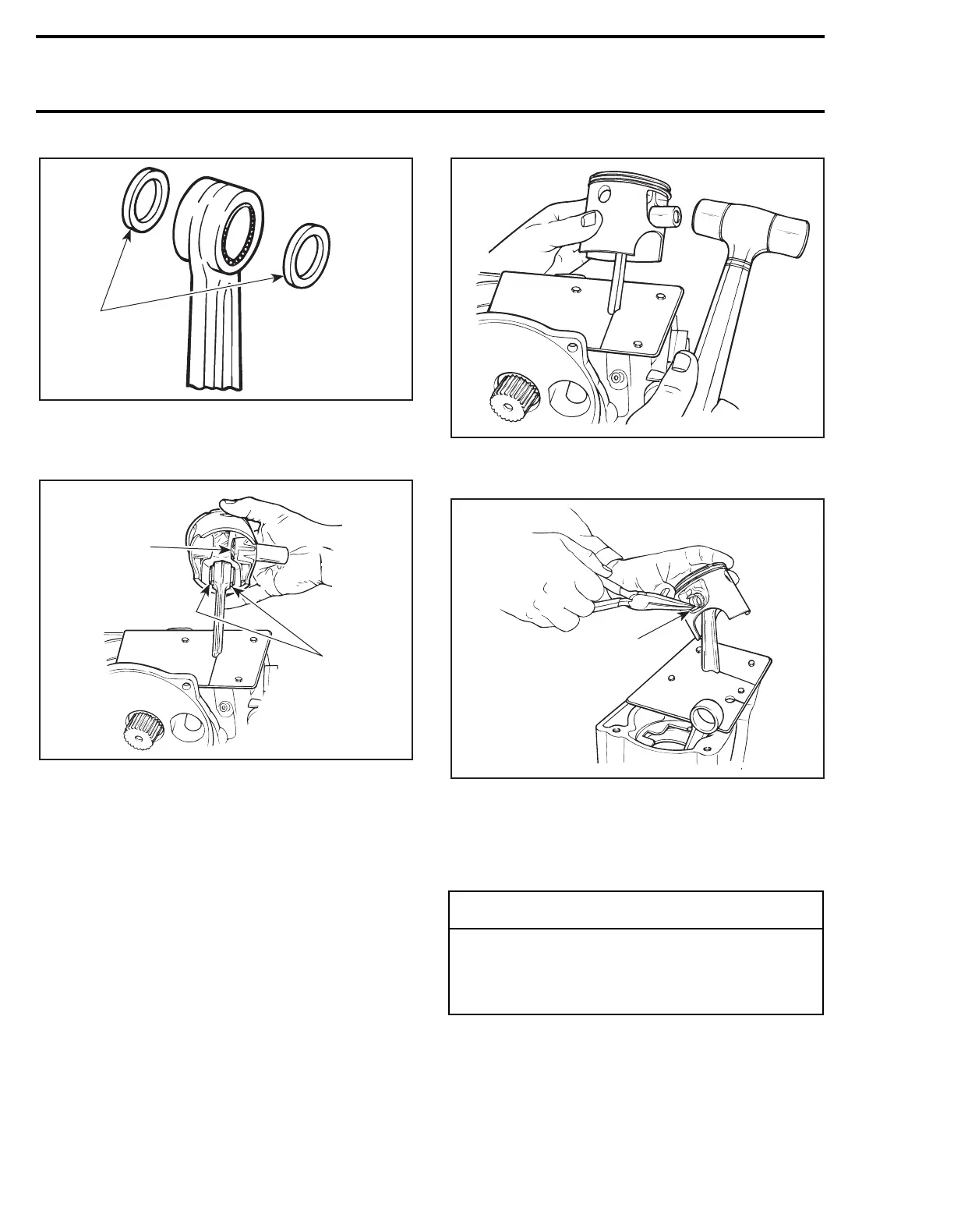

1. Thrust washer each side

– Insert piston pin into piston until it comes flush

with inward edge of piston hub.

1. Piston pin flush here

2. Thrust washers

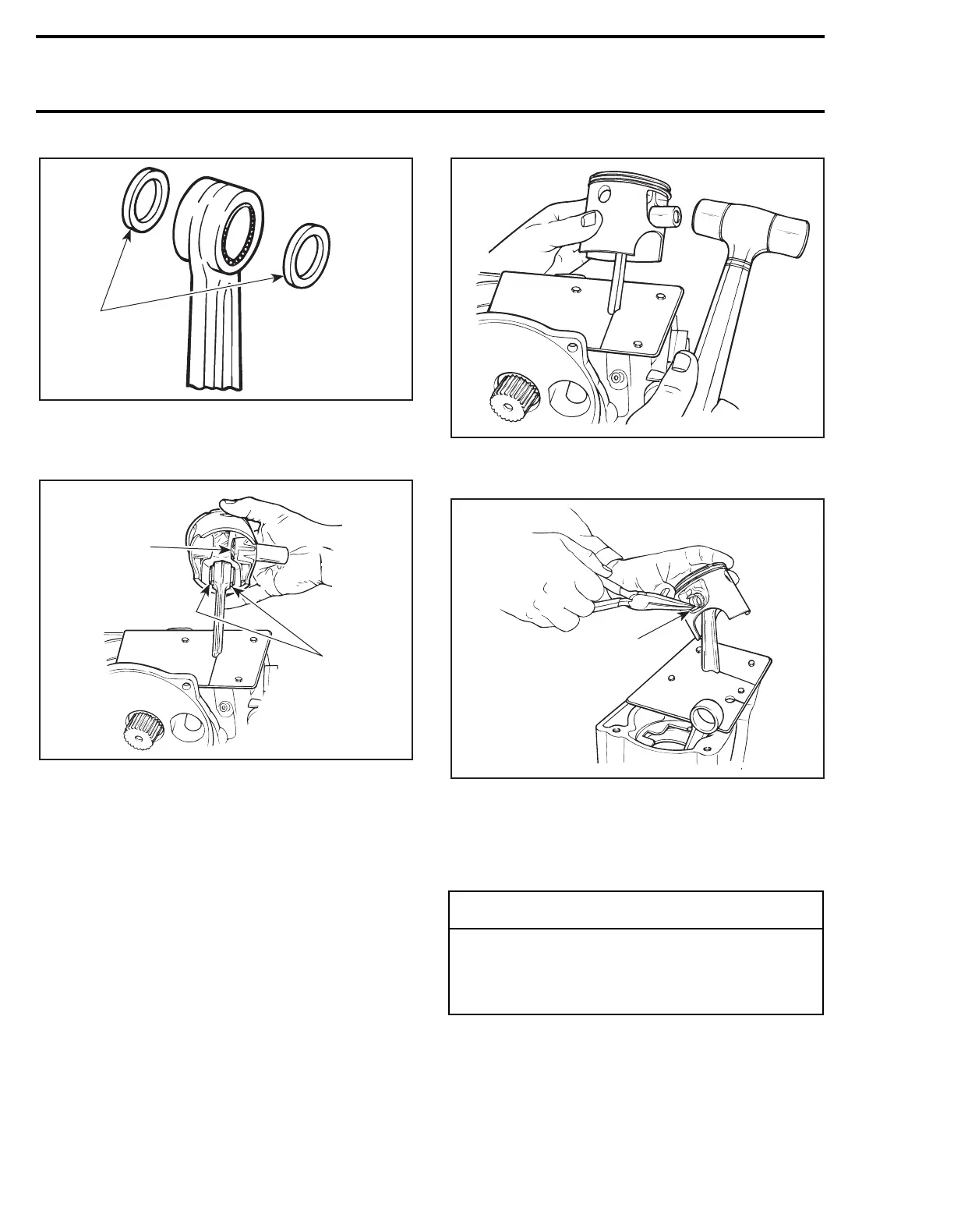

– Place piston over connecting rod and align

bores, then gently tap piston pin with a fiber

hammer to push out inner plastic ring on oppo-

site side. Support piston from opposite side.

– As necessary, pull halves of inner sleeve with

long nose pliers.

1. Pulling inner sleeve half

5, Circlip

Secure remaining circlip

no. 5

taking into consid-

eration the following.

F01D0VA

1

F01D0RA

1

2

-

CAUTION

To minimize the stress on the circlips, install

them so that their openings are located at 6

o’clock (at bottom). Always use new circlips.

At installation, take care not to deform them.

F01D0SA

F01D0TA

1

Loading...

Loading...