7-12

7

Setting and Operating Outlines

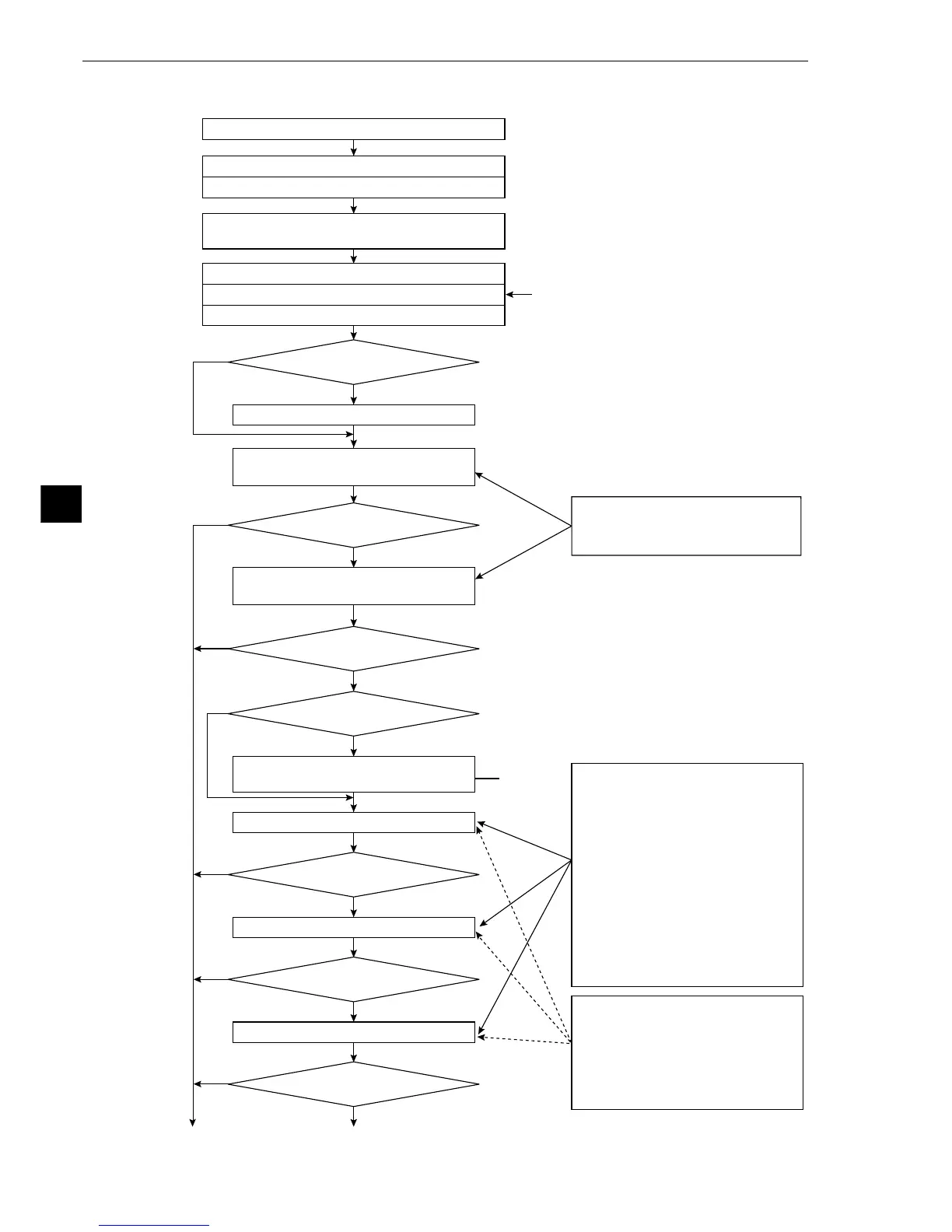

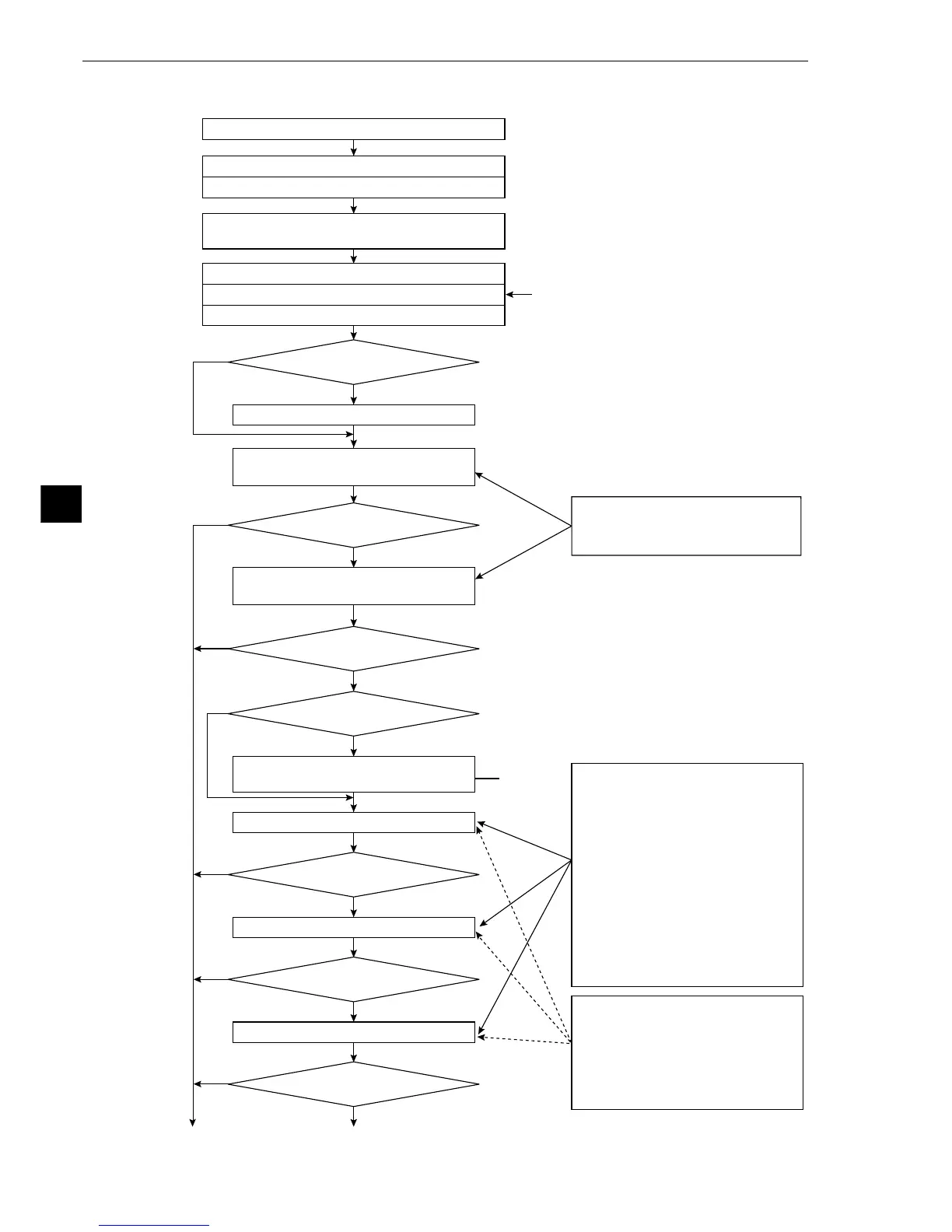

[2] Operation flow after a measurement start input signal is given

Yes

No

No

No

No

No

Yes

No

Yes

Yes

Yes

No

Yes

Yes

(*)

The window coordinates are

corrected within the range set for

each type of measurement,

based on the correction value

determined in the steps marked

with an (*)

Start (measurement start input ON)

Illuminance monitor set

External interface inhibit

(key, communications, parallel)

PC calculation

Parallel output (Y0 to Y15), "BUSY" ON

Executing illuminance monitoring

An error was detected

An error was detected

An error was detected

An error was detected

An error was detected

Executing measurement 1

Executing measurement 2

Executing measurement 3

Setting the coordinate correction

value (X, Y, θ)

① (To the next page)② (To the next page)

Positional correction

Executing measurement 0 using

camera 2

Executing measurement 0 using

camera 1

Measurement timer start

Reading the object type No.

Image capturing (camera 1/2)

The range of the lines to be captured,

as set in the measurement conditions,

is fetched.

[Measurement program to be

selected]

· Positional diviation measurement

[Measurement programs to select]

· Matching inspection for shape

and size

· Distance and angle measurement

· Lead inspection

· Area measurement after binary

conversion

· Counting by quantities by binary

conversion

· Label measurement by binary

conversion

· Detect existence using point

measurements

Loading...

Loading...