4.1 Periodic Inspection and Maintenance

It is necessary to perform periodic inspections of this instrument to ensure its safe use.

It is possible to have these periodic inspections performed by Shimadzu service personnel

on a contractual basis.

For information regarding the maintenance inspection contract, contact your Shimadzu

representative.

Turn off the main power switch on the back of the instrument and unplug

the power cable prior to maintenance when instructed.

Fire, electric shock or malfunction may occur.

For parts replacement, use parts and tools listed in "1.2 Component Parts" P.2

and "5.2 Maintenance Parts" P.130.

If any other parts or tools are used, part damage, injury, and malfunction may

occur.

Never remove the cover.

This may cause injury or a malfunction of the device.

Contact your Shimadzu representative if the cover must be removed.

4.1.1

Prior to Inspection and Maintenance

•

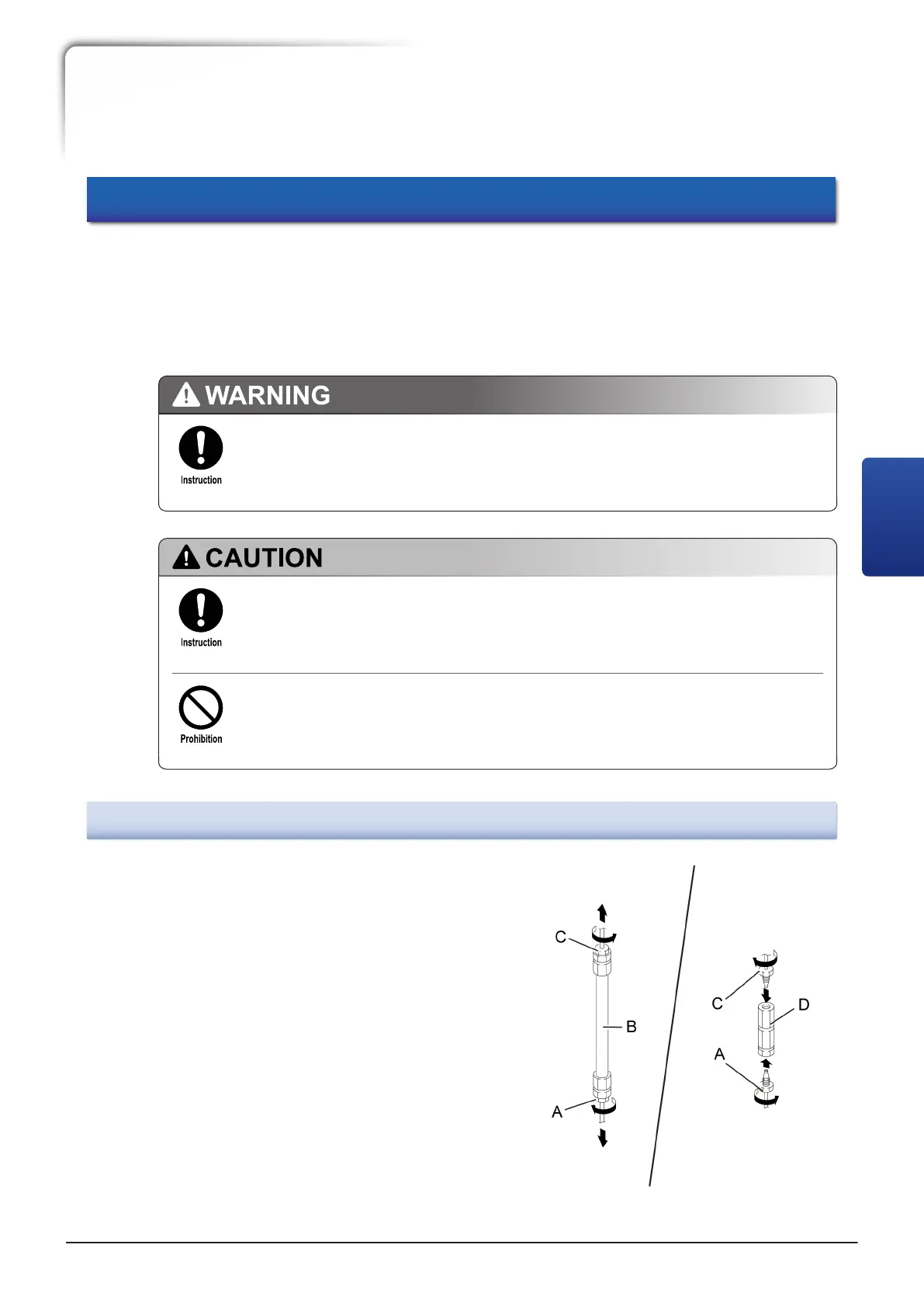

Loosen the male nuts (A and C) on the

column inlet and outlet with an 8-mm

wrench and then remove the column (B)

from the flow path. Attach the coupling

(D) to the male nut (A and C), and

tighten it with an 8 mm wrench.

• Replace the mobile phase in the flow

lines with at least 20mL of water.

When normal phase solvent was used,

replace the internal channel with

2-propanol and then with water.

• Wipe away any dirt from the front panel

and the main cover.

• Remove the right panel cover and filter

holder before starting the work. Release

4

Maintenance

LC-40D X3 CL LC-40D XR CL

79

4

Loading...

Loading...