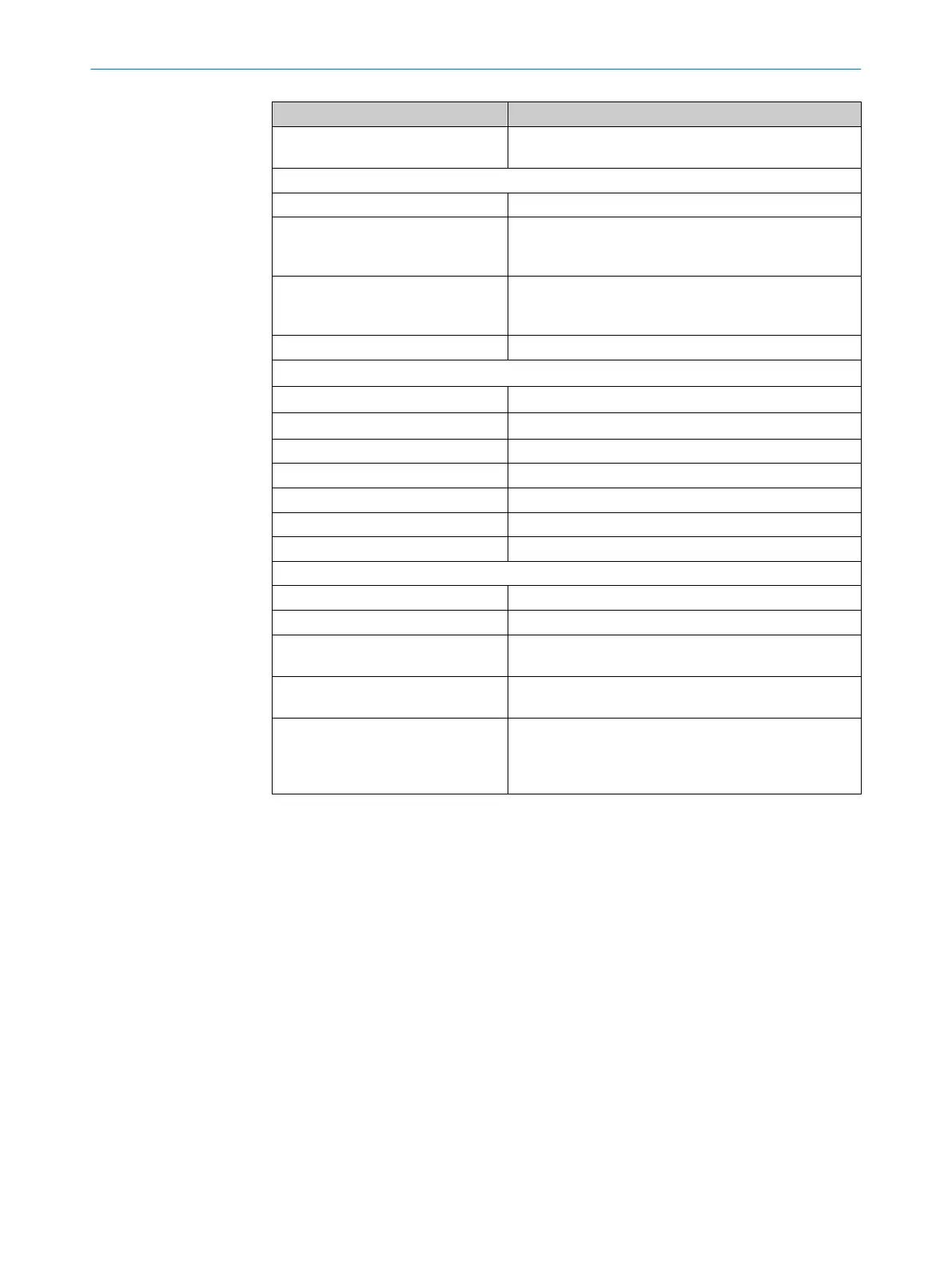

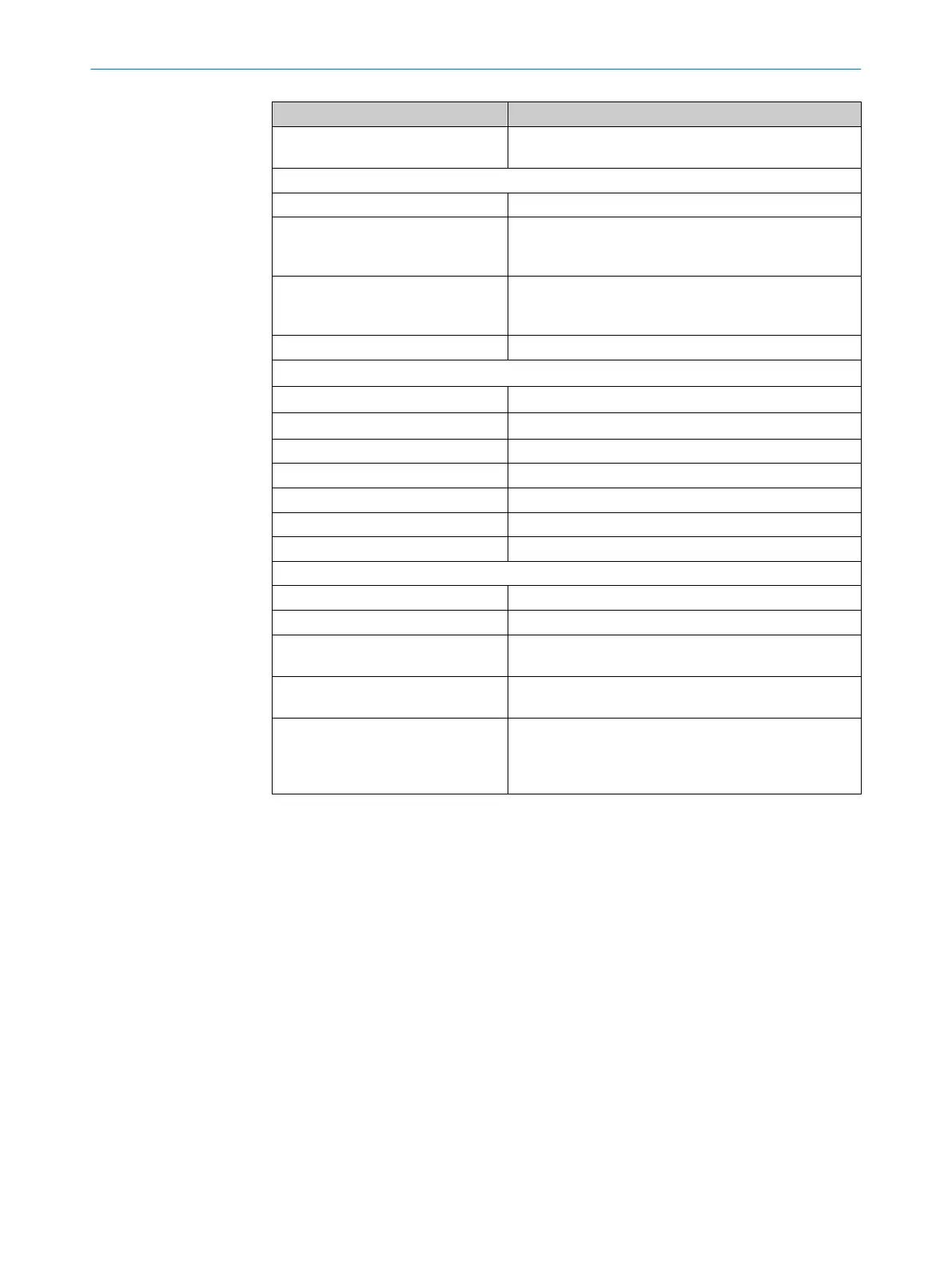

XTIO

Output voltage High 16 … 30VDC (max. 0.8V drop to terminal A1 of this

module)

Leakage current Low

Normal operation Max. 0.1mA

In the event of an error

1)

, H

ard‐

ware version <V1.10 (FX3-XTIO

Step1.xx)

Max. 1.6mA

In the event of an error

1)

, H

ard‐

ware version ≥V1.10 (FX3-XTIO

Step2.xx)

Max. 2.0mA

Output current Max. 2.0A

Sum current I

sum

T

U

≤45°C Max. 4.0A

T

U

≤55°C Max. 3.2A

UL/CSA applications Max. 3.2A

Test pulse duration (test gap)

2)

<650µs or deactivated

Test pulse rate (test period) Min. 200ms

Load capacity ≤0.5µF

Conductor resistance

3)

Max. 5Ω (e.g., 100m × 1.5mm² = 1.2Ω)

Max. permitted coil energy without external protection elements

4)

Hardware version V1.00 0.22J

Hardware version ≥V1.01 0.37J

Response time Depending on the logic configuration, for details see:

see

table 97, page 132

Synchronicity of outputs Qx within a

Flexi Soft station (time delay)

5)

Max. 1ms

Possible switching to High in the

e

vent of an internal hardware error

10ms or 50ms,

Details: see "Fault detection time and fault response

time when using single-channel outputs on the FX3-

XTIO", page 28

1)

In the event of an error (GND line open circuit) and with a load resistance of at least 2.5kΩ, no more than

t

he specified leakage current flows on the safety output. For lower load resistances, the leakage current

may be greater; however, the output voltage will be <5V in this case. A downstream device, for example

a relay or a FPLC (fail-safe programmable logic controller) must detect this state as Low.

2)

When activated, the outputs are tested regularly (brief switching to Low). When selecting the downstream

control elements, ensure that the test pulses with the specified parameters do not result in a switch-off,

or deactivate the test pulses on the outputs yourself.

3)

Make sure to limit the conductor resistance of the individual cables to the downstream controller to this

value in order to ensure that a short-circuit between the outputs is safely detected. (See also EN60204

Electrical equipment of machines, Part 1: General requirements.)

4)

Examples of the maximum resulting coil induction depending on coil current:

•

Hardware version V1.00: 1,760mH @ 0.5A, 440mH @ 1A, 110mH @ 2A

•

Hardware version V1.01: 2,960mH @ 0.5A, 740mH @ 1A, 185mH @ 2A

For inductive loads (e.g. contactors, relays and valves), no external protective elements are required if

this maximum coil energy is not exceeded.

RC elements parallel to the inductive load should not be used because these can create an oscillating

circuit that causes an overshoot in the positive voltage range once the induction voltage has decayed

and thereby trigger a cross-circuit error. The tolerated time for the overshoot (>3.5V) must be

observed:

•

Firmware version ≤V2.10.0: <1ms

•

Firmware version V2.11.0: <3ms

•

Firmware version ≥V3.00.0: <3ms or <43ms if an extended error detection time for switching

capacitive loads has been configured

The overshoot can be reduced if necessary using an external parallel resistance.

12 T

ECHNICAL DATA

144

O P E R A T I N G I N S T R U C T I O N S | Flexi Soft Modular Safety Controller 8012478/1IG6/2023-02-24 | SICK

Subject to change without notice

Loading...

Loading...