6 Assi

nin

Parameters to the Control and the PLC Pro

ram

6

03.96

6.12 System settings for power up, RESET and part program start

6-177

Siemens AG 2000 All Rights Reserved

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

6.12 System settings for power up, RESET and part program

start

The behavior of the control after

S Power up (POWER ON),

S Reset/part program end

S Part program start

can be changed with the machine data

MD 20110: RESET_MODE_MASK (definition of the control initial setting

after power up and reset) and

MD 20112: START_MODE_MASK (definition of the control initial setting

after part program start).

Table 6-25 Change system setting with MD

State Variable with MD

Power up (POWER ON) RESET_MODE_MASK

RESET/part program end RESET_MODE_MASK

Part program start START_MODE_MASK and

RESET_MODE_MASK

Select the required system behavior.

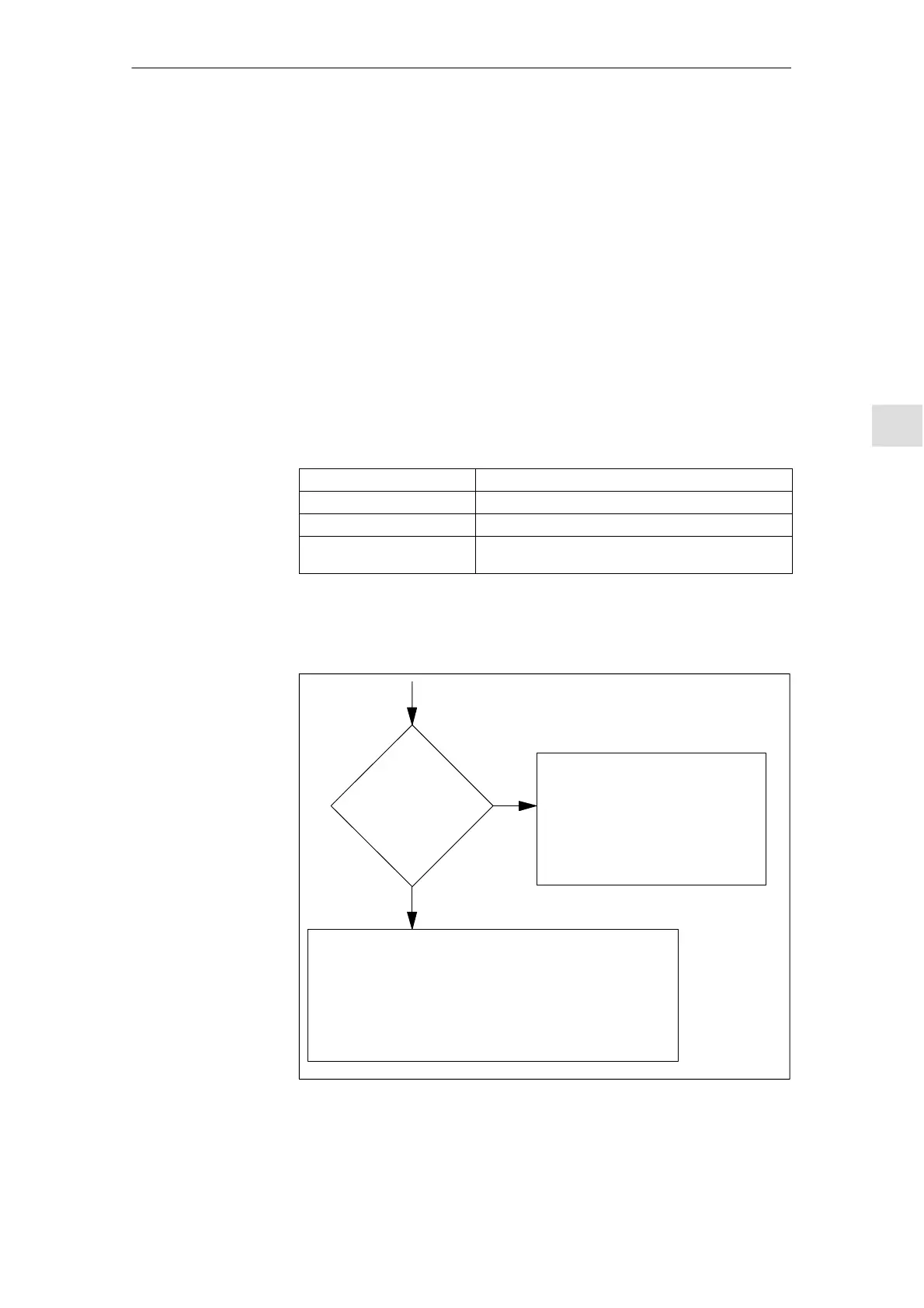

S After power up (POWER ON)

MD 20110: RESET_MODE_MASK, bit 0 = 0 or 1

Power up

(POWER ON)

MD 20110

RESET_MODE_MASK

bit 0

bit 0=0

bit 0=1

– G codes acc. to MD 20150: GCODE_

RESET_VALUES

– Tool length compensation not active

– Transformation not active

– No coupled-axis groupings active

– No tangential correction active

– not project. Synchronous spindle

coupling is deactivated

– G codes acc. to MD 20150: GCODE_RESET_VALUES

– Tool length compensation active to MD 20120: TOOL_RESET_

VALUE, MD 20121: TOOL_PRESEL_RESET_VALUE and

MD 20130: CUTTING_EDGE_RESET_VALUE

– Transformation active to MD 20140: TRAFO_RESET_VALUE

– No coupled-axis groupings active

– No tangential correction active

– Not project. synchronous spindle coupling is deactivated

Fig. 6-45 System settings after power-up

Concept

Procedure

Loading...

Loading...