6 Assi

nin

Parameters to the Control and the PLC Pro

ram

6

03.96

6.9 Axes and spindles

6-142

Siemens AG 2000 All Rights Reserved

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

6.9.14 Spindle configuration

Setpoints: MD 30100: CTRLOUT_SEGMENT_NR

MD 30110: CTRLOUT_MODULE_NR

MD 30120: CTRLOUT_NR

MD 30130: CTROUT_TYPE

Actual values:

MD 30210: ENC_SEGMENT_NR

MD 30220: ENC_MODULE_NR

MD 30230: ENC_INPUT_NR

MD 30240: ENC_TYPE

Note

For further information about spindle configuration, see above in this chapter in

the “Drive configuration” section.

6.9.15 Encoder matching (spindle)

For the purpose of matching the spindle encoder, the same machine data apply

as for the axis. MD 30300: IS_ROT_AX and MD 30310: IS_ROT_MODULO

must always be set for the spindle so that the encoder is always matched to one

revolution. IS_ROT_AX and MD 30310: ROT_IS_MODULO must always be set

for the spindle so that the encoder is always matched in relation to one

revolution. In order to obtain a display which is always referring to 360 degrees,

MD 30320: DISPLAY_IS_MODULO must be set. If the motor encoder of the

611D system is used for the purpose of encoder matching, then the encoder

matching data must be entered for each individual gear stage if several gear

stages are present. The maximum multiple of the 611D drive is always used as

the maximum multiple of encoder lines. This multiple is 2048.

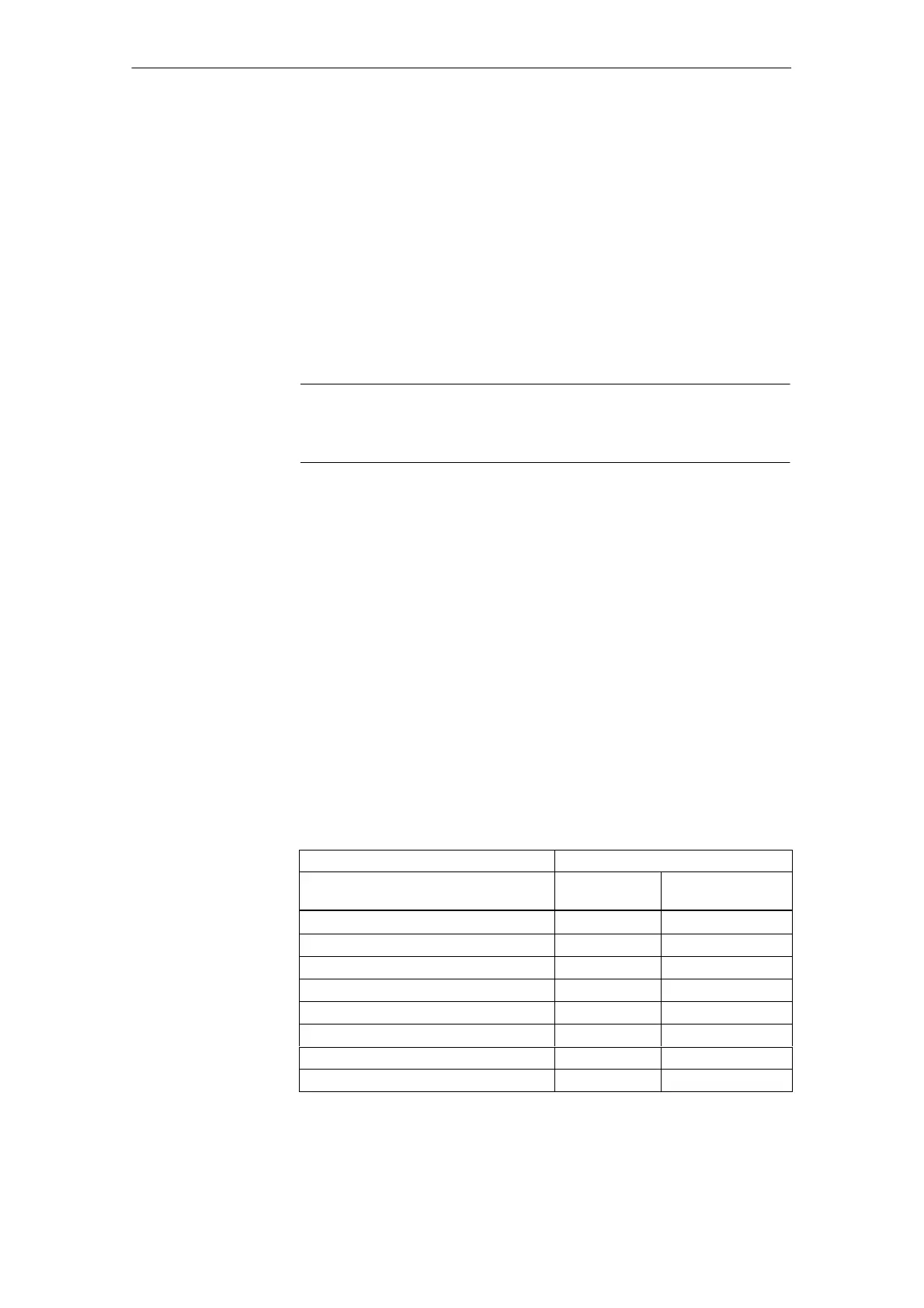

Table 6-20 Machine data for encoder matching

Machine data Spindle

Encoder on

motor

Encoder on spindle

30300: IS_ROT_AX 1 1

31000: ENC_IS_LINEAR 0 0

31040: ENC_IS_DIRECT 0 1

31020: ENC_RESOL Lines/rev. Lines/rev.

31080: DRIVE_ENC_RATIO_NUMERA Motor rev. Load rev.

31070: DRIVE_ENC_RATIO_DENOM Encoder rev. Encoder rev.

31060: DRIVE_AX_RATIO_NUMERA Motor rev. See following note

31050: DRIVE_AX_RATIO_DENOM Load rev. See following note

Machine data for

setpoints and

actual values

Encoder matching

via machine data

Loading...

Loading...