3

03.96

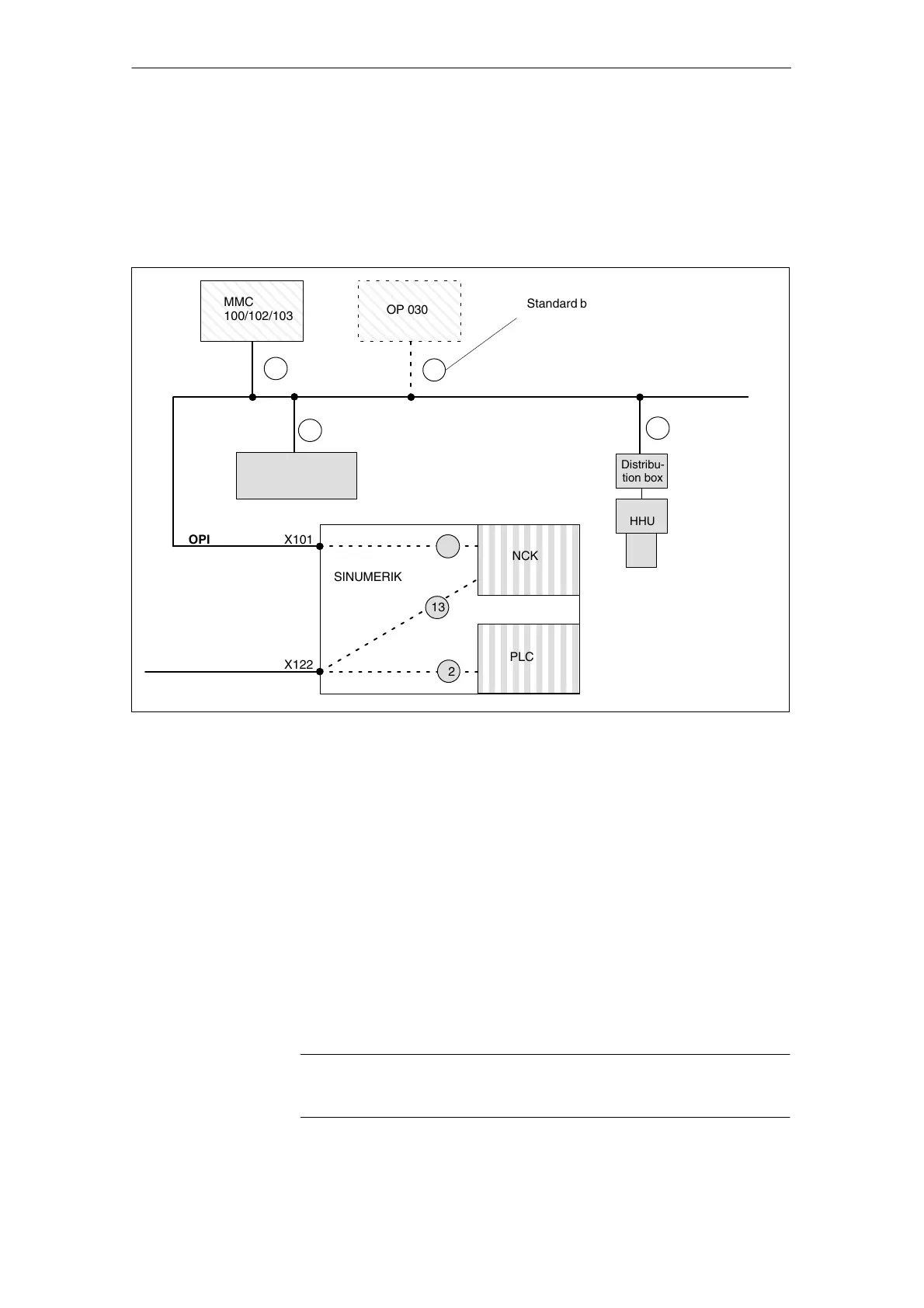

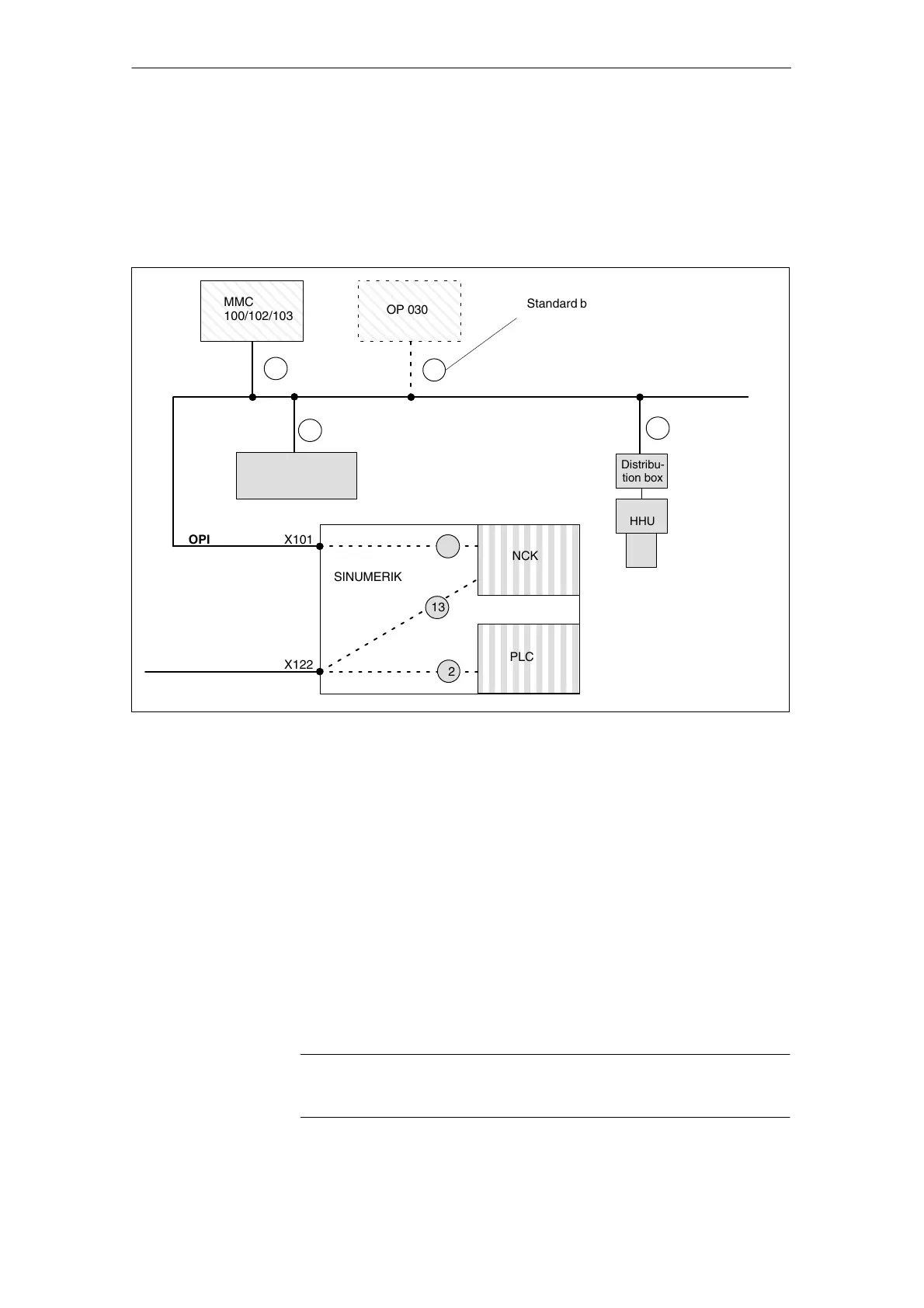

3.3 Connection of a 2nd MCP/customer OPI and/or 1 HHU (up to SW 3.1)

3-46

Siemens AG 2000 All Rights Reserved

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

3.3.3 Example of a configuration of MCP and HHU via OPI

S MCP with firmware version V 03_01_01

S HHU with firmware version V 01_01_02

MMC

100/102/103

OP 030

1

10

1 MCP

15

6

OPI

NCK

PLC

X101

SINUMERIK 840D

MPI

187.5 kbaud

13

13

2

X122

OPI

Distribu-

tion box

HHU

Standard bus

addresses

Fig. 3-6 Example of configuration of MCP and HHU via OPI

The following parameter settings must be made for the MCP and HHU operat-

ing components in FB1.

MCPNum:=1 (one MCP)

MCP1In:=P#E0.0 (MCP input signals)

MCP1Out:=P#A0.0 (MCP output signals)

MCP1StatRec:=P#A12.0 (status double word)

MCP1StatSend:=P#A8.0 (status double word)

MPIBusAdr:=6

BHG:=2 (HHU on OPI)

BHGIn:=P#M20.0 (HHU input signals)

BHGOut:=P#M0.0 (HHU output signals)

BHGStatRec:=P#M26.0 (status double word)

BHGStatSend:=P#M30.0 (status double word)

The other HHU parameters are set to appropriate defaults.

See FB basic program.

Note

Note the DIP switch settings (switches S1 and S2 in the HHU).

Preconditions

Parameterization

of basic PLC

program FB1

3 Settin

s, MPI / OPI

Loading...

Loading...