Detailed Description

2.3 Tool cutting edge

Basic logic functions: Tool Offset (W1)

48 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Basic length 1 to 3

In order that the discrepancy between the toolholder reference point F and the toolholder

reference point F' can be corrected on the three geometry axes (three dimensional), all 3

basic lengths are active irrespective of the tool type. In other words, a twist drill (tool type

200) with a tool length compensation (length 1) can also have a tool base dimension/adapter

dimension in 3 axes.

Note

Please refer to the following documentation for more information about base-

dimension/adapter-dimension tool length compensation:

References:

/PG/Programming Manual Fundamentals

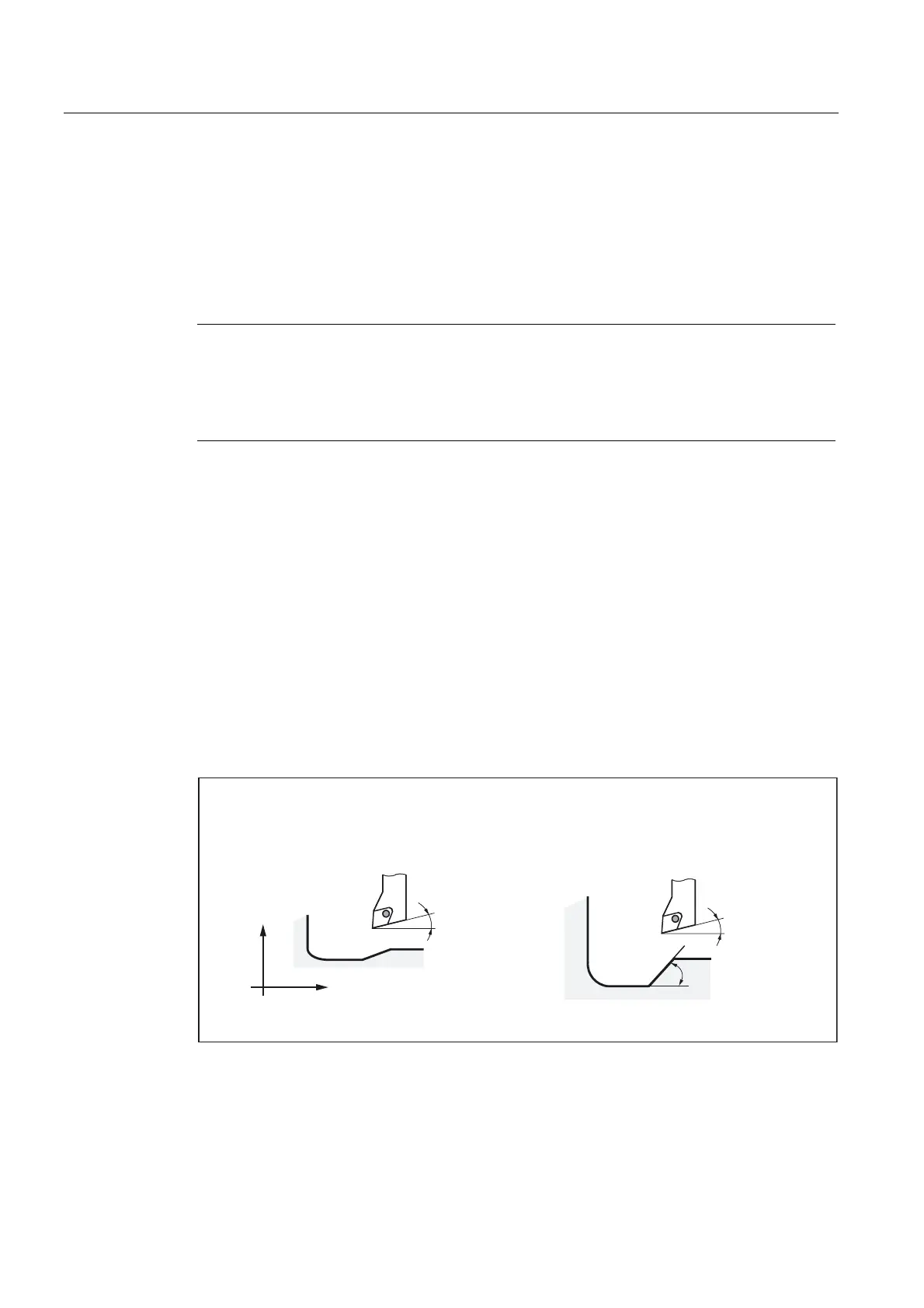

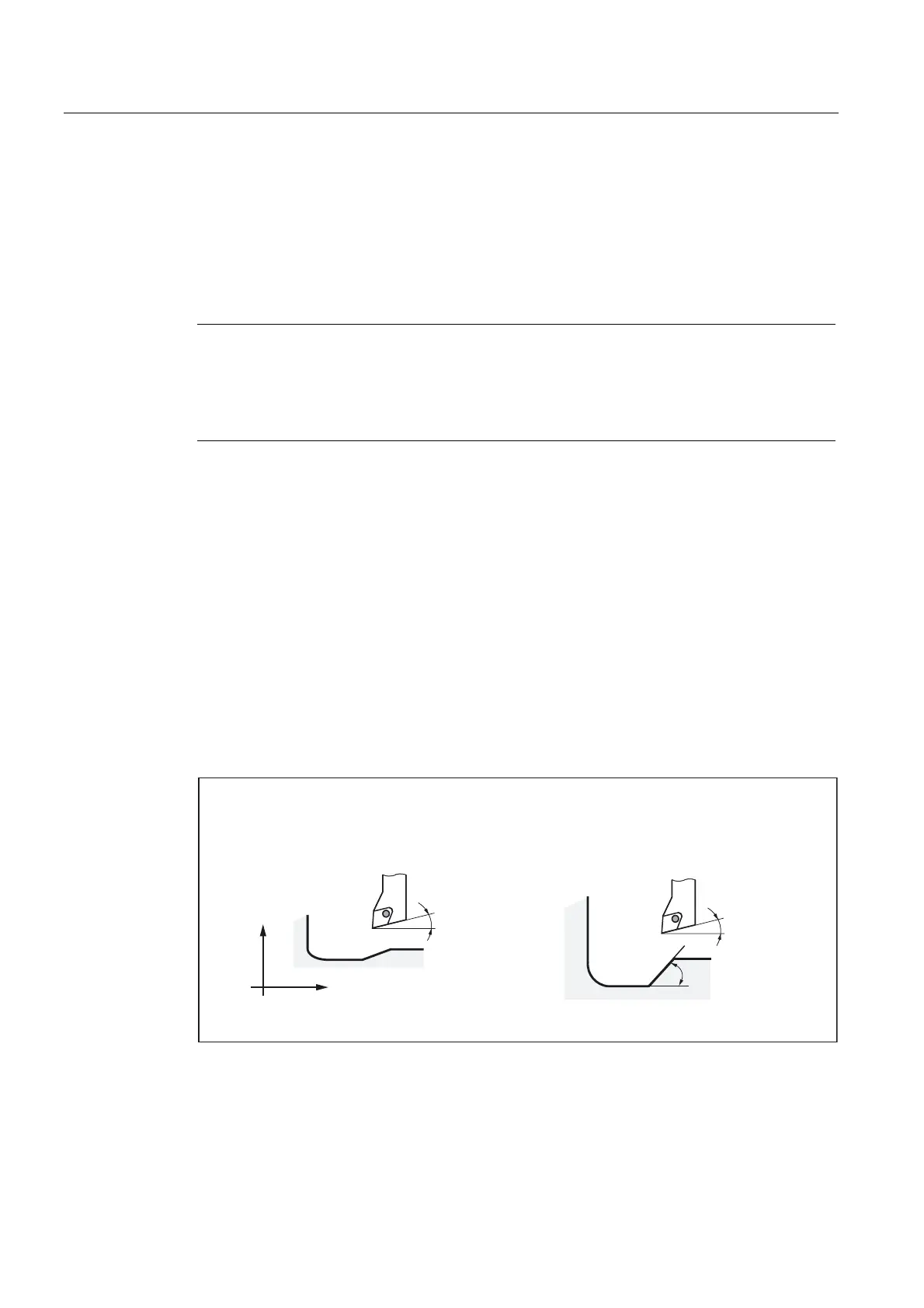

2.3.9 Technology - tool clearance angle (tool parameter 24)

Meaning

Certain turning cycles, in which traversing motions with tool clearance are generated,

monitor the tool clearance angle of the active tool for possible contour violations.

Value range

The angle (0 to 90° with no leading sign) is entered in tool parameter 24 as the tool

clearance angle.

VWFRQWRXUWREHPDFKLQHG

LVQRWYLRODWHG

QGFRQWRXUWREHPDFKLQHG

FRXOGEHYLRODWHG

7RROFOHDUDQFH

DQJOH

7RROFOHDUDQFH

DQJOH

;

=

Figure 2-12 Tool clearance angle of the turning tool during relief cutting

Loading...

Loading...