Detailed Description

2.7 Basic tool orientation

Basic logic functions: Tool Offset (W1)

128 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

2.7 Basic tool orientation

Application

Normally, the orientation assigned to the tool itself depends exclusively on the active

machining plane. For example, the tool orientation is parallel to Z with G17, parallel to Y with

G18 and parallel to X with G19.

Different tool orientations can only be programmed by activating a 5axis transformation. The

following system variables have been introduced in order to assign a separate orientation to

each tool cutting edge:

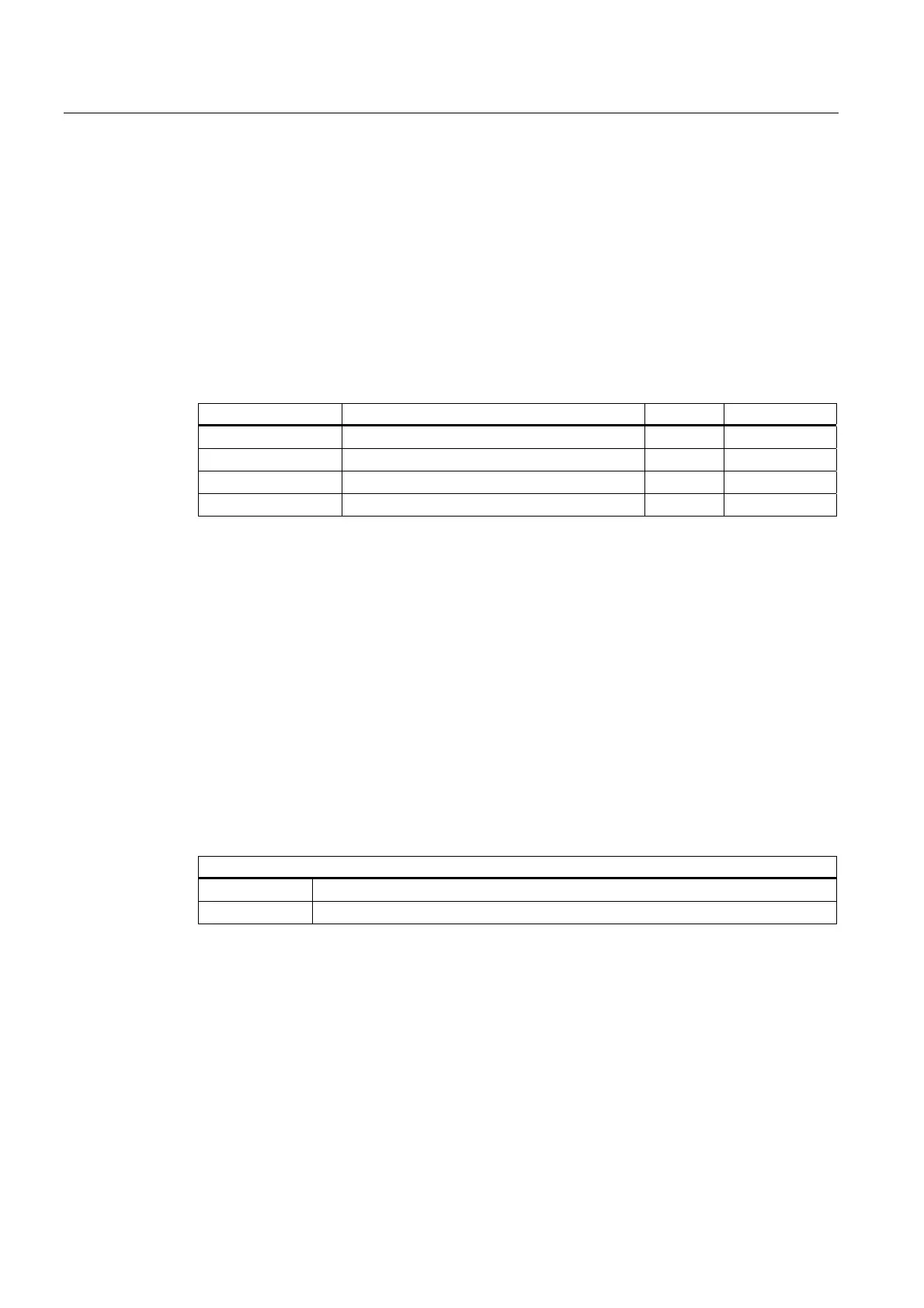

System variable Description of tool orientation Format Preassignment

$TC_DPV[t, d] Tool cutting edge orientation

INT

0

$TC_DPV3[t, d] L1 component of tool orientation

REAL

0

$TC_DPV4[t, d] L2 component of tool orientation

REAL

0

$TC_DPV5[t, d] L3 component of tool orientation

REAL

0

Indexing: Same as tool system variable $TC_DPx[t, d]

t: T number of cutting edge

d: D number of cutting edge

Identifiers $TC_DPV3 to $TC_DPV5 are analogous to identifiers $TC_DP3 to $TC_DP5 of

the tool length components.

MD18114

The system variables for describing the tool orientation are only available if machine data is

not equal to zero:

MD18114 $MN_MM_ENABLE_TOOL_ORIENT (assign orientation to tool cutting)

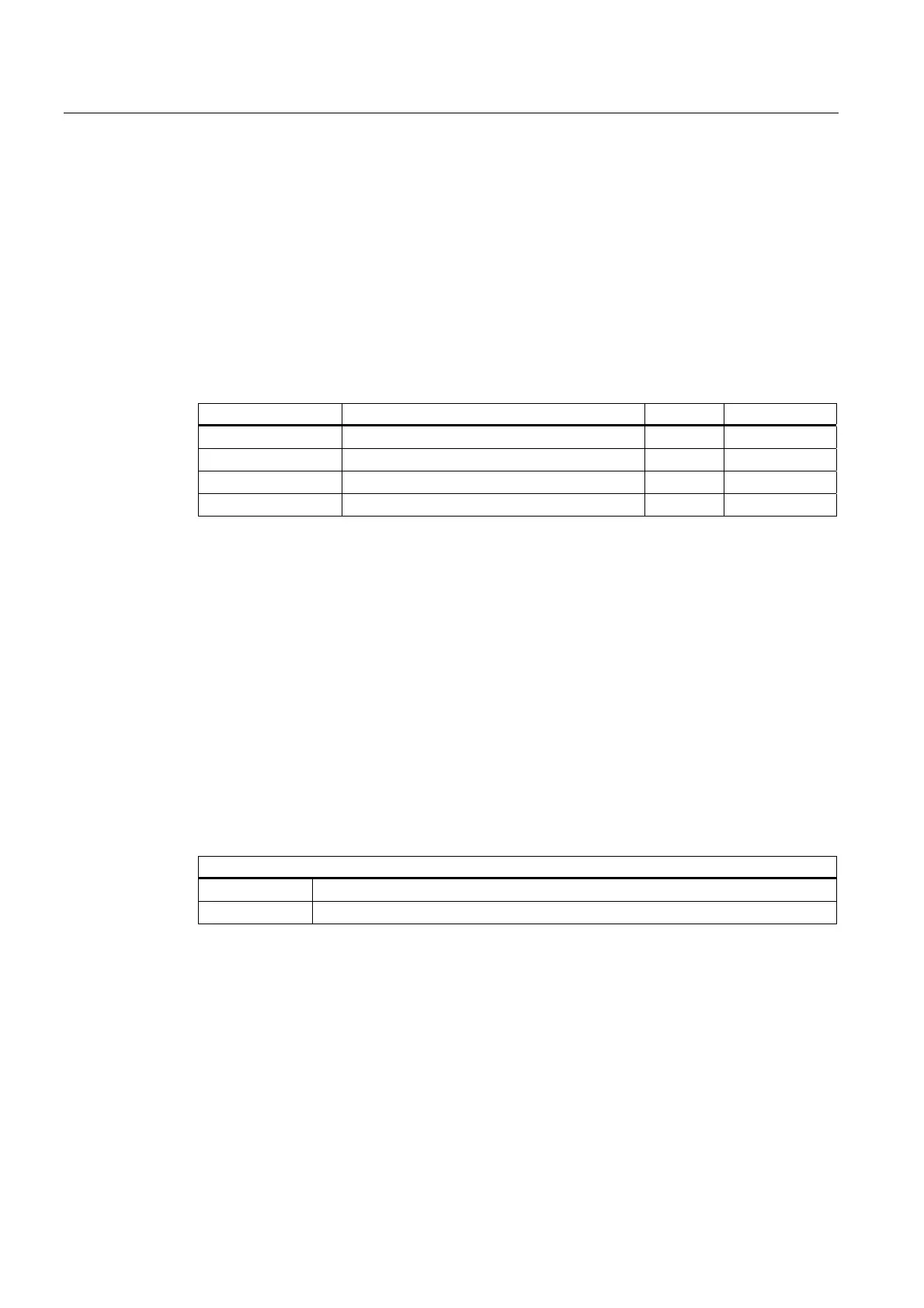

MD18114 $MN_MM_ENABLE_TOOL_ORIENT

Value = 1 Only system variable $TC_DPV[t, d] is available.

Value = 2 All four system variables are available.

Loading...

Loading...