Detailed Description

2.14 Reference point approach (R1)

Basic logic functions: NC/PLC interface signals (Z1)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

113

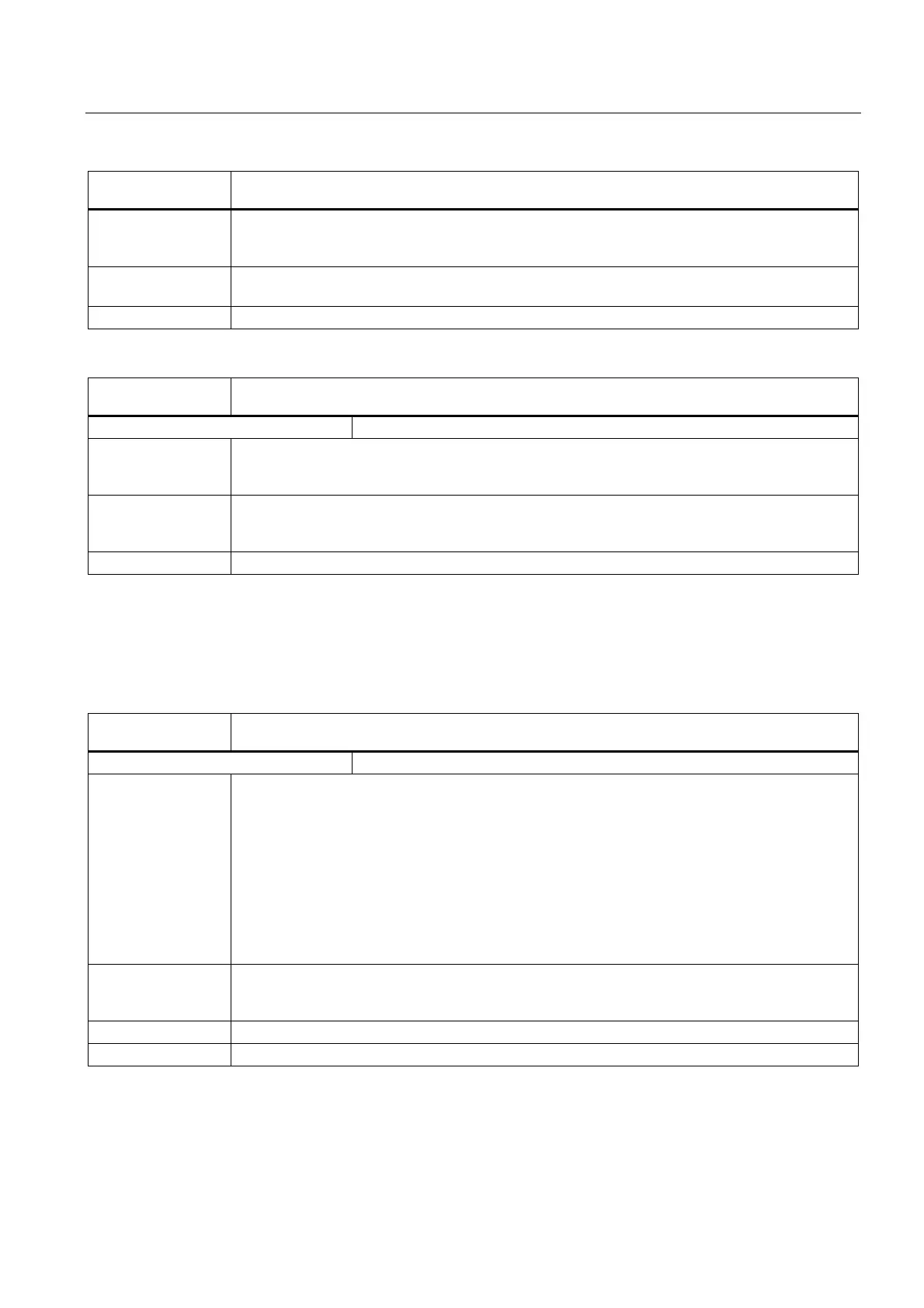

DB31, ...

DBX2.4 - DBX2.7

Reference point value 1 to 4

Application

example(s)

On a machine tool with large traversing distances, four coded reference cams can be distributed

over the entire distance traveled by the axis, four different reference points approached and the

time required to reach a valid referenced point reduced.

Special cases,

errors, ......

If the machine axis has arrived at the reference point and none of the four "reference point value 1

to 4" interface signals has been set, the value of the reference point is automatically set to 1.

Corresponding to .... MD34100 $MA_REFP_SET_POS (reference point value)

DB31, ...

DBX12.7

Reference point approach delay

Edge evaluation: no Signal(s) updated: cyclic

Signal state 1 or

edge change

0 → 1

The machine axis is positioned on the reference cam.

Signal state 0 or

edge change

1 → 0

The machine axis is positioned in front of the reference cam. An appropriately long reference cam

(up to the end of the traversing range) should be used to prevent the machine axis from being

located behind (after) the referencing cam.

Corresponding to .... DB31, ... DBX2.4 - DBX2.7 (reference point values 1 to 4)

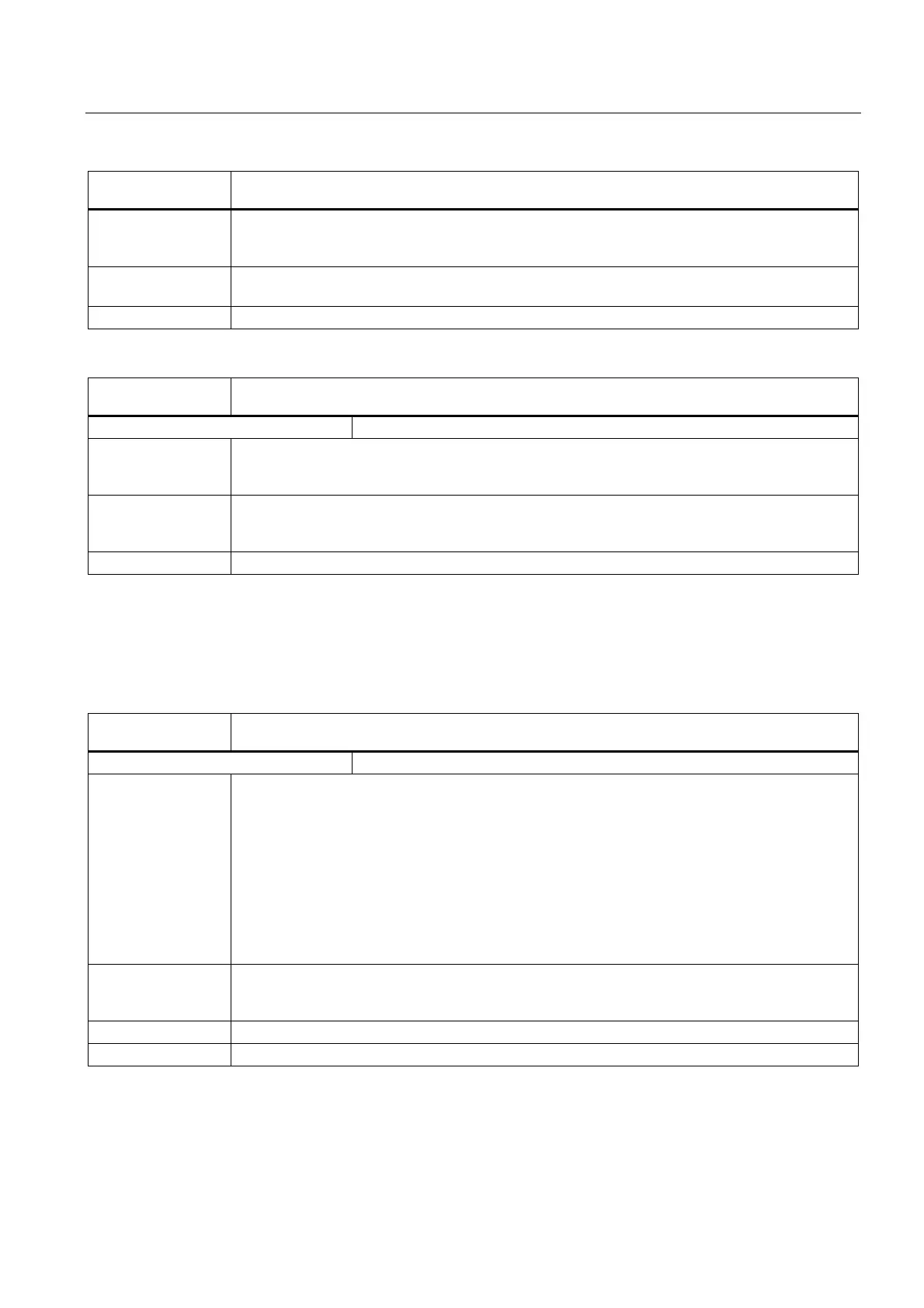

2.14.4 Signals from axis/spindle (DB31, ...)

DB31, ...

DBX60.4

Referenced/synchronized 1

Edge evaluation: Signal(s) updated:

Signal state 1 or

edge change

0 → 1

Axes:

When being referenced, if the machine axis has reached the reference point (incremental

measuring systems) or the target point (for length measuring system with distance-coded reference

marks), then the machine axis is referenced and the following interface signal is set:

DB31, ... DBX60.4 (referenced/synchronized 1)

(depending on which position measuring system is active when referencing).

Spindles:

After power-on, a spindle is synchronized the latest after one spindle revolution (260 degrees) (the

zero mark passed or the Bero responded).

Signal state 0 or

edge change

1 → 0

The machine axis/spindle with position measuring system 1 is not referenced/synchronized.

Corresponding to .... DB31, ... DBX1.5 (position measuring system 1)

Additional references /FB1/ Functions Manual Basic Functions; Spindles (S1)

Loading...

Loading...