Examples

4.2 Examples 3-6: SETTCOR function for tool environments

Basic logic functions: Tool Offset (W1)

196 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Example 8

N10

def real _CORVAL[3]

N20

$TC_DP1[1,1] = 500 ; Turning tool

N30

$TC_DP3[1,1] = 10.0 ; Geometry L1

N40

$TC_DP4[1,1] = 15.0 ; Geometry L2

N50

$TC_DP5[1,1] = 20.0 ; Geometry L3

N60

$TC_DP12[1,1]= 10.0 ; Wear L1

N70

$TC_DP13[1,1] =0.0 ; Wear L2

N80

$TC_DP14[1.1] =0.0 ; Wear L3

N90

$SC_WEAR_SIGN = TRUE

N100

_CORVAL[0] = 10.0

N110

_CORVAL[1] = 15.0

N120

_CORVAL[2] = 5.0

N130

rot y 30

N140

t1 d1 g18 g0

N150

r1 = settcor(_CORVAL, "W", 1, 1)

N160

t1 d1 x0 y0 z0 ; ==> MCS position X7.990 Y25.000

Z31.160

In N90 the setting data is enabled:

SD42930 $SC_WEAR_SIGN (sign of wear)

i.e. the wear must be valued with a negative sign.

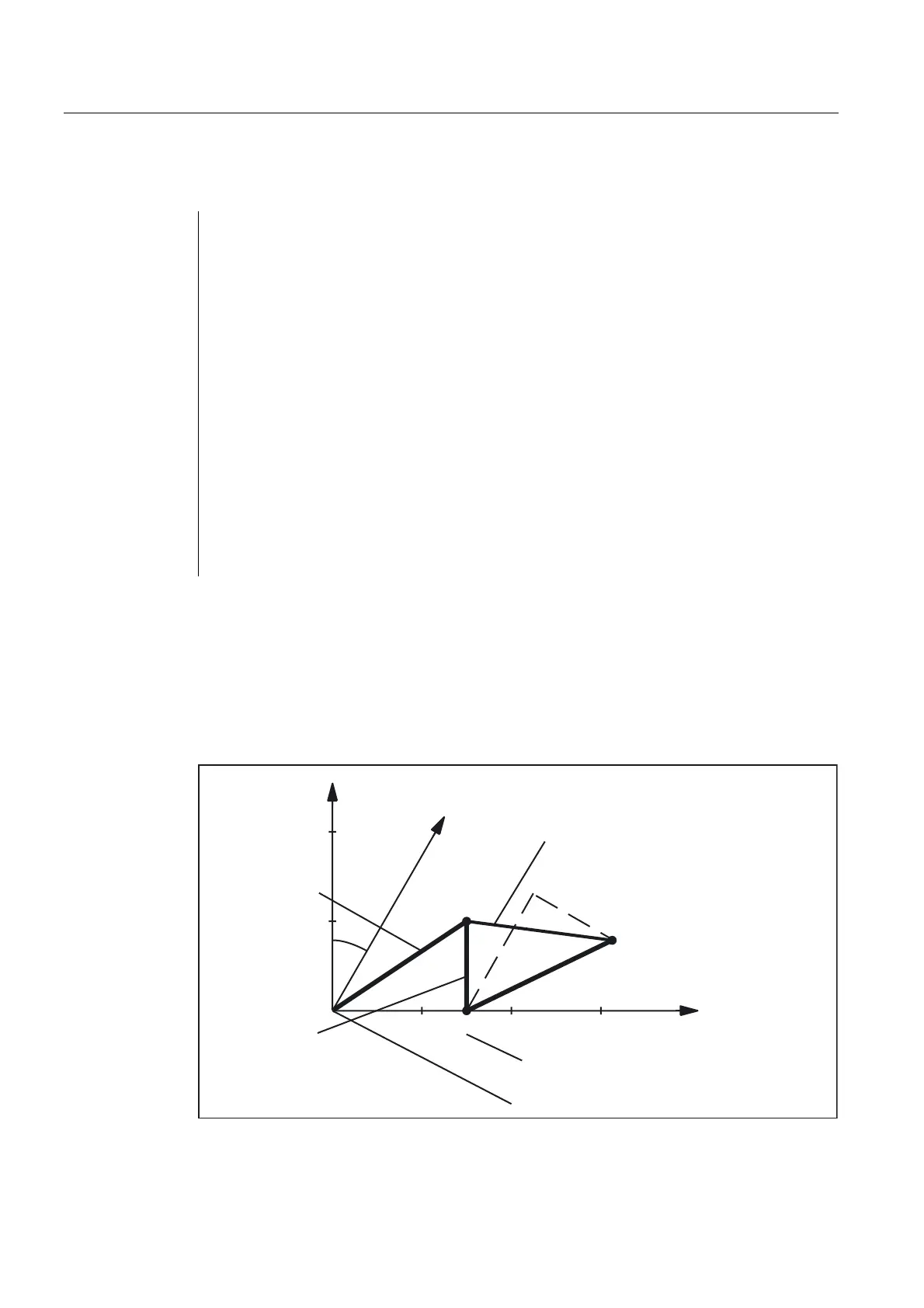

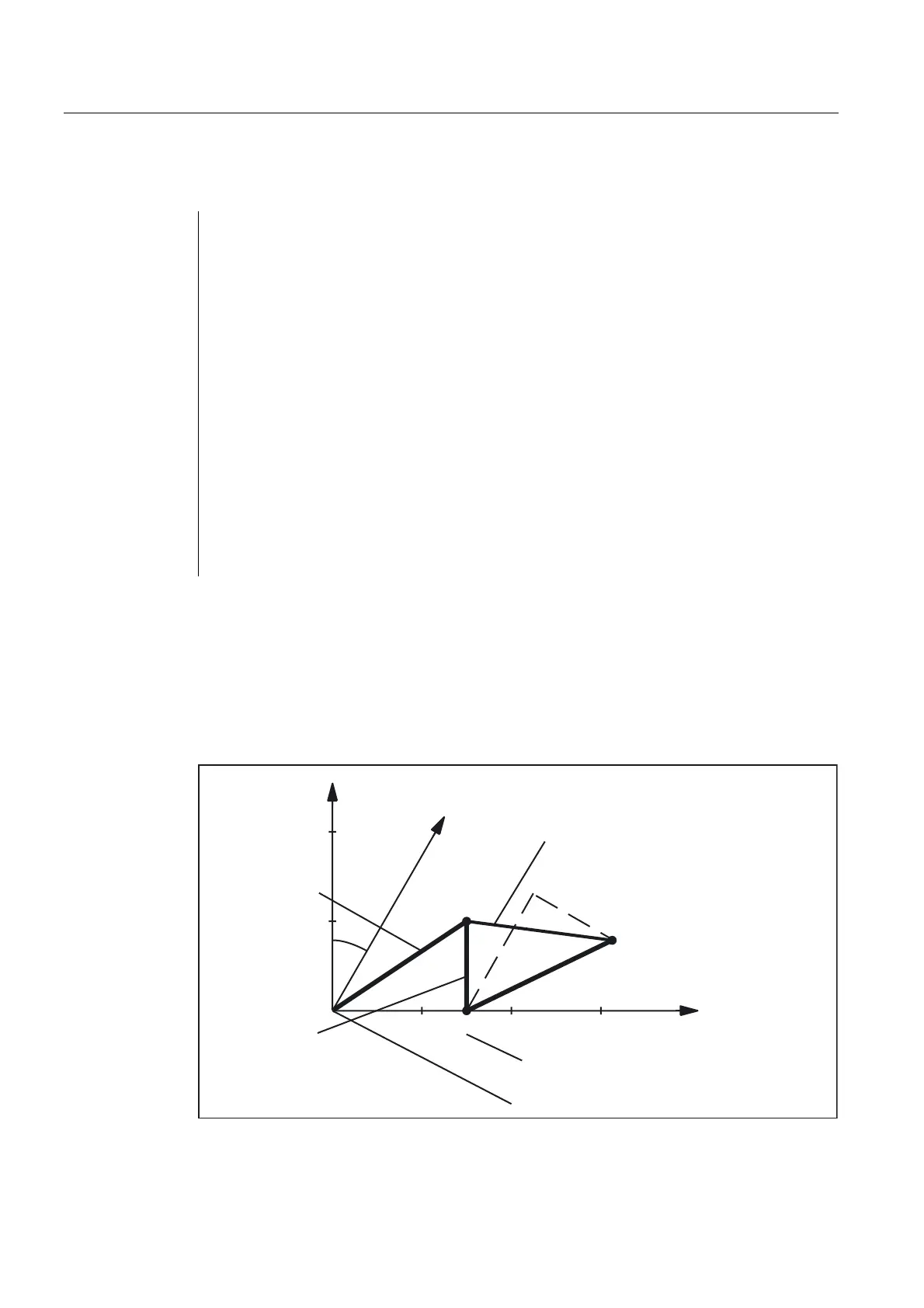

The compensation is vectorial (_CORCOMP = 1), and the compensation vector must be

added to the wear (_CORMODE = 1). The geometric conditions in the Z/X plane are shown

in the figure below:

3

=

=

3

3

;

;

B&259$/< ; =

*HRPHWU\

/ /

:HDU/ /

QHJDWLYHHYDOXDWLRQ

5HVXOWLQJZHDUFRPSRQHQW

2ULJLQDOWRROOHQJWK

Figure 4-2 Tool length compensation, example 8

Loading...

Loading...